Project Summary

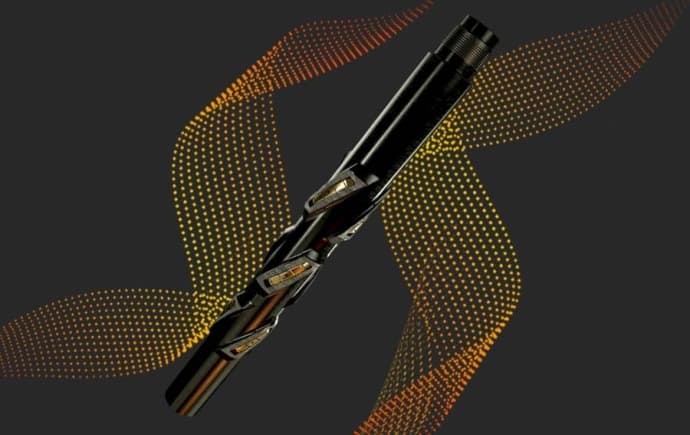

Coretrax Activated Drilling Scraper (ADS) incorporated into the cement drilling BHA saves rig time by eliminating need for a dedicated scraper run to optimize CBL results.

Project Details

The Coretrax Activated Drilling Scraper (ADS) was run on a recent plug and abandonment (P&A) project for a North Sea Operator. To abandon the well, the client planned to drill out 2x existing cement plugs and the upper +/-275ft of a 3rd, to provide an adequate sump above the top reservoir depth to allow a casing scraper to be run and clean the casing ahead of logging. It was then planned to scrape the casing ID across the Cement Bond Log (CBL) interval, to ascertain the existence of cement behind the 9 5/8” casing.

Solution

To reduce the number of cleanout runs, it was preferred to run a scraper in the initial BHA, although this would only be possible if the scraper remained dormant in the string making the Activated Drilling Scraper the best solution for the application.

The Coretrax ADS remains dormant in the drill string, this allows drilling and any other operations to be completed before the scraper is hydraulically activated. The design of the tool allows a wide range of casing weights to be covered and a choice of activation ball sizes to suit the ID of the BHA. Multiple drilling scrapers can be run in tandem to scrape different casing IDs simultaneously. The ADS is a robust design featuring high torque premium connections, suited to both vertical and high angle applications. The scraper blades provide 360° coverage, eliminating the requirement to rotate the string.

The depth of the lowest cement plug and existing bridge plug determined the positioning of the ADS in the string, which was below jars, accelerators, and drill collars with a small ID, dictating the requirement to use a smaller activation ball.

The assembly was made up and RIH, successfully drilling the 2 cement plugs, before drilling the top 280ft of the 3rd plug, with varying parameters. Once drilling was complete, the string was POOH to 7300ft, baseline parameters recorded before the activation ball was dropped and pumped down with 80gpm/290psi. Shear out was observed with a 900psi pressure spike indicating that the scraper had activated, and the blades were engaged and ready to scrape the casing. The ADS washed in hole scraping casing from 7300-8650ft at 10ft/min (ADS depth at 8615ft and 500gpm without rotation). Once area scraped a drill pipe single was laid out to work the full stand before the well was circulated clean and the mud conditioned, ahead of logging.

Achievement

This successful run with the ADS eliminated the requirement for a dedicated scraper run in preparation for the CBL log, saving our client over 5 hours of valuable rig time.