Decommissioning is a major consideration in the global oil and gas industry in 2021 decommissioning expenditure totalled £1.2 billion and is expected to ramp up to £2.5 billion per year over the next decade.

With over 4,000 development wells awaiting plugging and abandonment (P&A) along with many partially suspended or partially abandoned wells that require final abandonment. Providing a solution that is cost-efficient, competent, and safe is paramount as operators look to reduce decommissioning costs by more than a third.

Safe, Simple and Low-Cost P&A

Confidently setting an environmental barrier for P&A operations has traditionally been limited to complex and costly mechanical bridge plugs and inflatable devices.

To meet the demand for a safe, simple and significantly cost-effective solution for big bore cement plug placement Coretrax, offers the CX-Enviroplugs. It is available as part of the Coretrax’s wide range of abandonment products and services and is particularly suited to wells requiring an environmental barrier to prevent the leakage of oil-based mud.

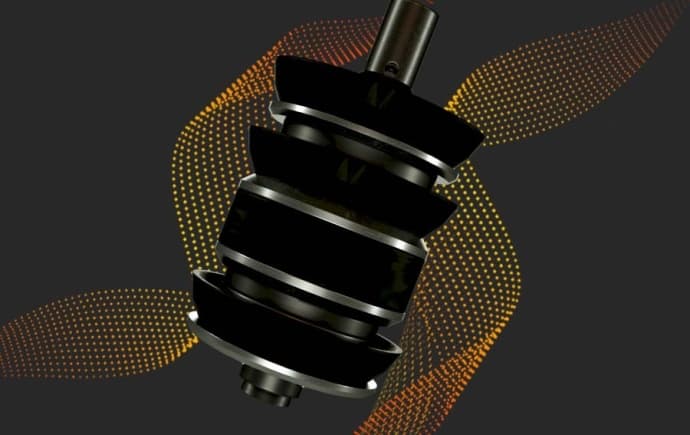

The CX-Enviroplug allows the option of pressure testing in larger ID casing. Available in sizes 18-5/8” to 20”, the three-finned tool, which allows self-centralization, incorporates a compression set element. The inclusion of a compression set elastomer in the design allows for a pressure test of up to 1,000psi to be achieved. The tool is also able to pass through a smaller wellhead restriction.

The plug is run on the drill pipe and once at depth, a ball is dropped, and pressure applied to shear out the disconnect sub. This leaves both the lower section of the disconnect sub, and the plug, downhole. Once released, an open-ended slick stinger remains, allowing cementing to take place immediately. The disconnect tool utilized on the CX-Enviroplug is also suitable for other applications.

Manufactured from drillable materials, the device also boasts a one-way valve and bypass ports across the plug to prevent surging when running in hole.

North Sea P&A Activity

As part of an abandonment project within the UKCS, Coretrax delivered bridge plugs for the permanent abandonment of several wells. Coretrax ran a 13-3/8” CX-2 bridge plug, a permanent cast iron bridge plug, the CX-2 is designed to set with a combination of hydraulic pressure and mechanical pull and boasts a built-in setting mechanism for greater efficiency. The slick OD and large ID of the released running tool minimizes cement disturbance when pulling out of hole. This makes it ideal for cement plug operations.

The bridge plug was made up and run in hole to a setting depth of 232m and set by the operators own personnel as per Coretrax procedures. It was then tagged with 10k lbs and tested to 500psi with a primary release seen upon return to surface.

As part of the batch environmental cap operations, two CX-Enviroplugs were also deployed by the operator. Here, the disconnect sub was made up to the drill pipe and the plug made up to the string and run in hole. The 13-3/8” casing stump was then tagged at 220m, and weight set down to set the plug. A ball was dropped from surface to activate the disconnect tool and pressure increased to 2,200psi. As per procedure, a pressure drop was then observed, the disconnect sub sheared, and the plug disconnected. An open-ended stinger is left, and cementing was carried out. This successful run resulted in the well being fully abandoned.

The main advantage of using the fully-drillable CX-Enviroplug is that it significantly reduces cost by eliminating the need for a mechanical base for the environmental cap. In the abandonment campaign, Coretrax achieved a rig-time saving of approximately 48.7 hours.