Case Study

22” BRUTE® deployed for safe and quick wellsite evacuation

Contact

In Brief

Expro's industry-leading 22" BRUTE® Storm System - 2021 World Oil Award finalist for Best Well Integrity technology

Product Line

Region

Customer Challenges

- Hurricane Ida was rapidly intensifying in the Gulf of Mexico while our long-standing deepwater customer was drilling out their 18” hole section after just cementing the 22” casing in place

- To evacuate from the wellsite safely and quickly, our customer elected to run an isolation barrier in 22” casing to temporarily suspend operations

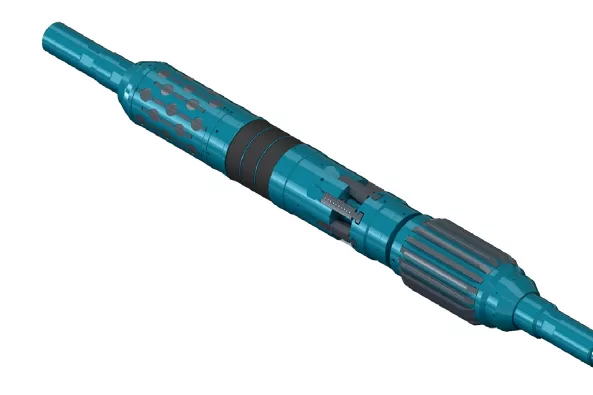

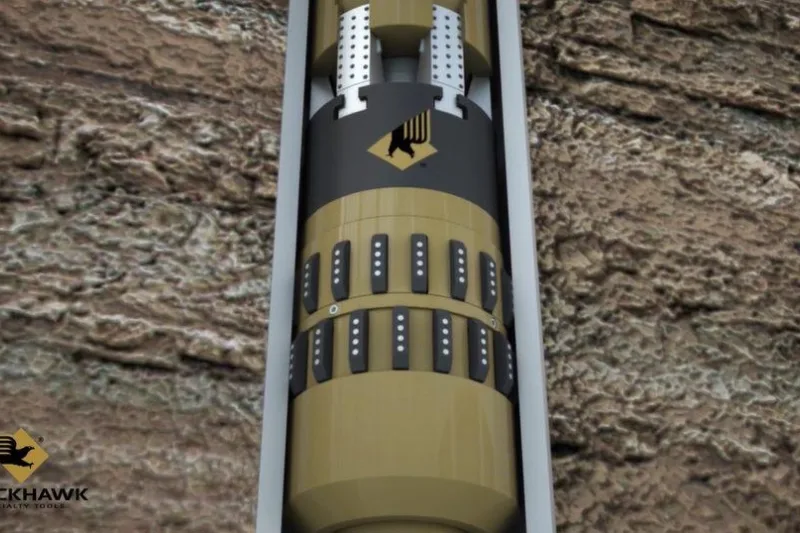

- Our 22” BRUTE® Storm System was selected because it is the industry’s only retrievable service packer for this casing size with the capability to handle required hang-off weights and test pressures

- The packer system was available onboard because it was previously mobilized to the rig for casing/casing shoe testing contingencies

Expro Excellence

- This application of Expro’s industry-leading 22” BRUTE® Storm System used our BRUTE® 22” Service Packer, which is a 2021 World Oil Award finalist for Best Well Integrity Technology

- The system is API 11D1 compliant for reliable quality and performance control, a key differentiator among retrievable service packers

- Its modular design minimized the amount of equipment required on rig location; therefore, reducing operational costs while covering multiple planned and unplanned scenarios and applications

- The simple and robust design allowed our customer to set and retrieve the packer faster, significantly increasing operational efficiencies and rig time savings

Value to Client

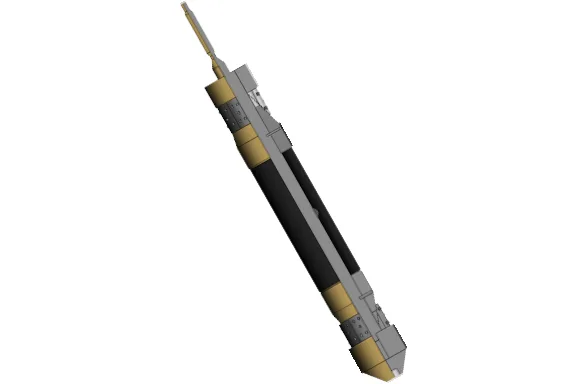

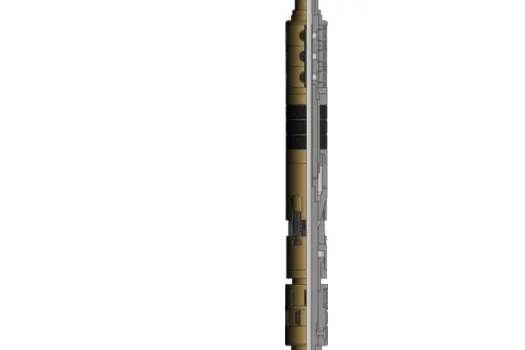

- The high tensile, fully mechanical 22” BRUTE® Storm System was quickly and safely deployed on the first attempt, allowing the rig ample time to prepare for the evacuation

- Once deployed in the well, the system suspended 110,000 lbs of drill pipe from the packer, allowing our customer to implement a successful integrity test of 1,200 psi before releasing from the packer and disconnecting from the well to move the drillship to a safe zone

- The retrievable design of the system also reduced rig time required to resume normal operations by eliminating the need for drill out operations required when using traditional suspension methods, such as cement retainers and/or cement plugs

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU