Well Flow Management

Expro provides flow measurement, reservoir characterization, and production data to optimize operations and maximize your financial returns.

Optimize production, maximize profit

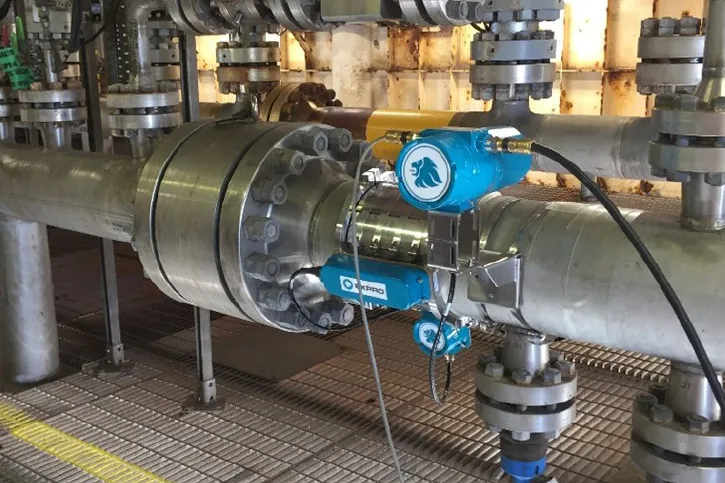

Our expertise in well testing, reservoir characterization, production optimization, and pipeline integrity enhances your well lifecycle.

From Exploration to Abandonment and beyond

Expro delivers decision-ready data, optimized production, and sustainable flow management across the entire well lifecycle. Our solutions extend from the reservoir to the export line, helping operators improve efficiency, reduce emissions, and safeguard integrity.

The five pillars of Well Flow Management

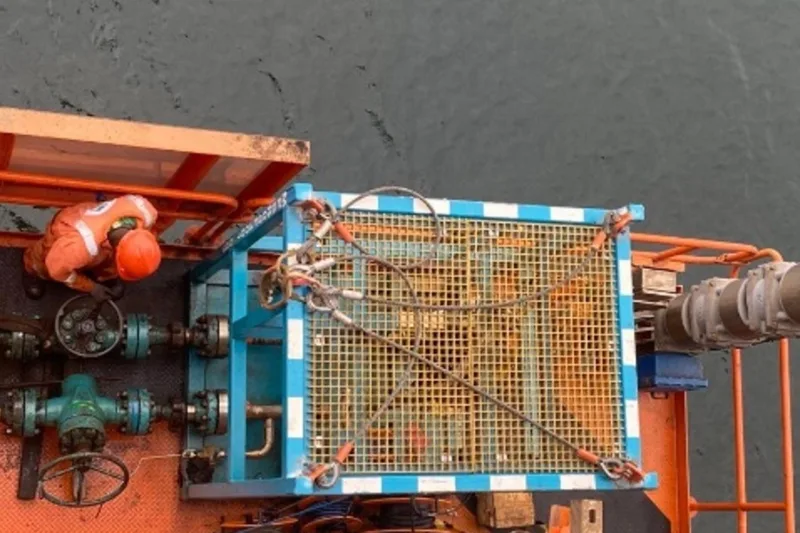

- Well Test

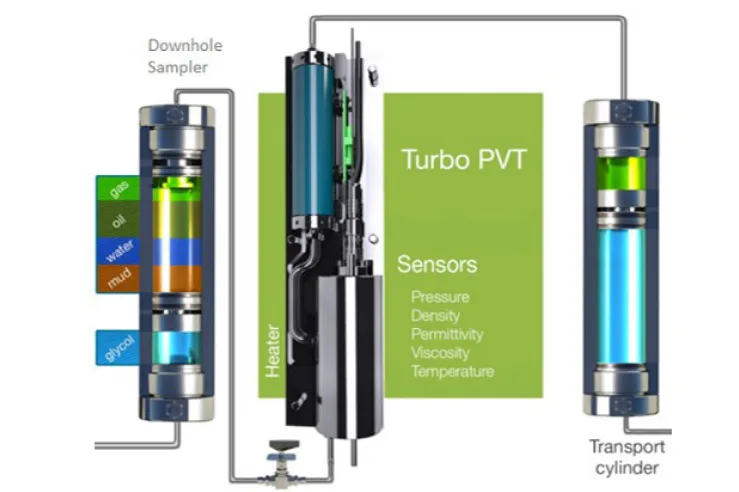

- Reservoir Characterization

- Production Optimization and Flow Assurance

- Pipeline Integrity

- Edge – Data to Desk

Downloads

- Harsh environment HPHT Gas-Condensate Production Clean-up experiences - Kristin Field

- Integrating Quantitative and Qualitative Rock Strength Data in Sanding Prediction

- Lessons Learned From Statfjord A Oil Spill and Actions Taken to Reduce Spill Risk

- Wellbore Cleanup Best Practices – A North Sea Operator’s Experiences

Get in touch

Contact Well Flow Management

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU