Case Study

DST tools withstand extreme-duration exposure

Contact

In Brief

Expro’s DST equipment was left in the well for a total duration of over 14 months, being exposed to harsh downhole conditions of over 14,000psi and 270°F

Product Line

Region

Customer Challenges

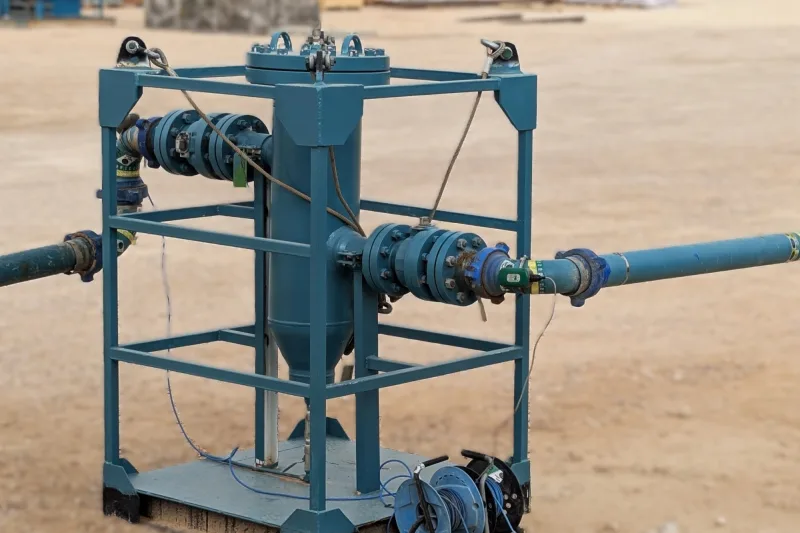

- Expro provided downhole Drill Stem Test (DST) services as part of an established contract with a national oil company

- In Q1 2020 an offshore exploration well was successfully tested, and downhole test objectives were completed without any issues. However, prior to the pull out of the hole an unexpected nonoperational delay arose and further DST operations were put on hold

- This unexpected development resulted in Expro’s DST equipment being left in the well for a total duration of over 14 months, being exposed to harsh downhole conditions of over 14,000psi and 270°F throughout

Expro Excellence

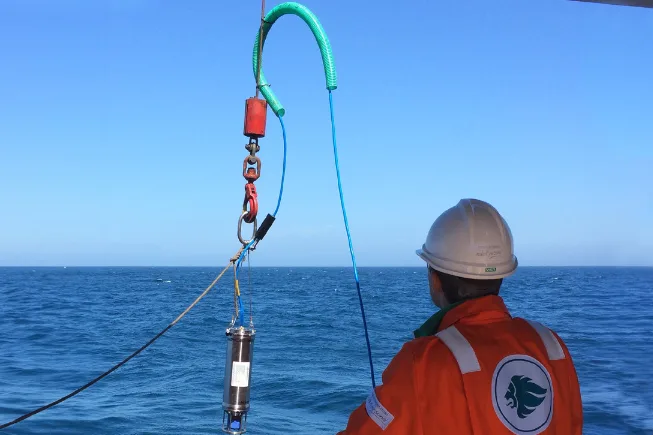

- Once operations resumed, the Expro DST equipment was pulled out of the well and returned to the Expro base without issue, avoiding any costlyor time-consuming fishing or milling operations

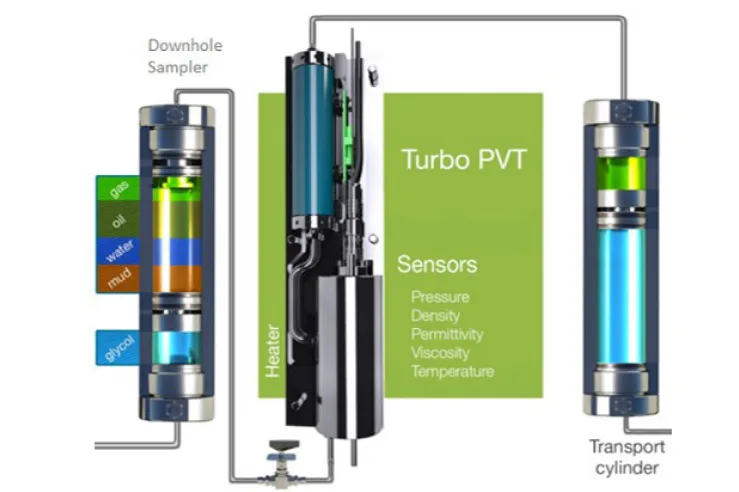

- By reviewing the well conditions during pre-job planning and fitting specially-selected premium elastomer compounds, the Expro Ops team had ensured the DST tools remained in excellent condition despite the exposure being many times longer than planned. Full trapped nitrogen precharge within the tools confirmed that no leak had taken place over the entire duration downhole

- Workshop testing of the multi-cycle tester valve confirmed that even after the extreme exposure it was still able to hold pressure and function well, demonstrating the robust and reliable design

- The Expro Ops team worked closely with Expro engineering to thoroughly inspect tool metalwork, using a range of specialist inspection techniques to verify integrity. This was able to confirm that despite the aggressive downhole conditions no significant degradation had occurred and tools remained fit for service

Value to Client

- The robust Expro DST equipment ensured there were no complications when it came to pulling tools out of the well, and as a result the client was able to return the rig back into service without additional cost or delay

- The reliability of the Expro DST equipment provided the client with further confidence that the Expro Ops team have the knowledge and capability to configure tools to be optimal for specific downhole conditions

- The durability of the Expro DST equipment allowed it to be refurbished and returned to active service for the client without the additional costs or delay should it have needed replaced

- The data gained from the unique tool exposure allowed Expro to further enhance the knowledge base and procedures for planning any future operations where a non-routine long exposure maybe encountered

Contact

For further information, please contact DST-TCP@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU