Case Study

Delivering high quality, onsite fluids analysis with Expro's ELITE composition

In Brief

Expro enabled on-rig compositional analysis, ensuring fluid sample integrity and quality, accelerating reservoir evaluation and decision-making by more than two months

Product Line

Customer Challenges

- Expro’s client needed to obtain reservoir compositional and contaminant data as part of a high profile E&A campaign in Southern Europe

- Good quality samples were a key objective of the campaign, and the operator required assurance that the samples were captured correctly and there were no nonconformities

- With no PVT laboratory in the area, samples would need to be exported for analysis, and their quality would not be known until they had reached the lab

- Decisions on whether to proceed with next steps of the operation required input from sample analysis

- If samples were not representative, no further opportunities would be available to re-sample

Expro Excellence

- Expro’s proposed solution delivered on the rig data, providing confidence in sample quality, as well as initial composition and contaminant data to confirm the value of the reservoir fluids

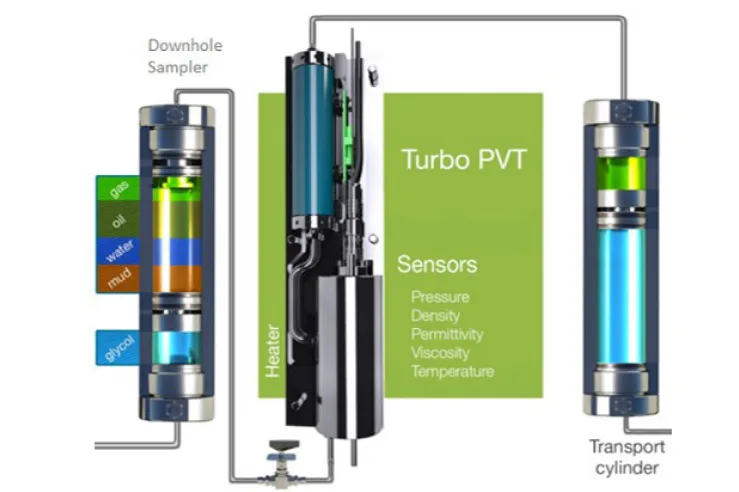

- TurboPVT transfers were used to validate samples during transfer from openhole tool to transport bottle, recording transfer progress and providing phase volumes, mud contamination levels, and pressurized density measurements

- ELITE Composition delivered C36+ hydrocarbon composition of the reservoir fluids, including BTEX (Benzene, Toluene, Ethylbenzene, and Xylenes), CO₂, and N₂, as well as GOR and stock tank liquid density

- Further onsite analysis was conducted on the samples, including mercury and hydrogen sulfide in the hydrocarbons, and ionic composition of two water samples by MultiIon analyzer

Value to Client

- All samples were transferred, ensuring their integrity by restoring to reservoir conditions and maintaining single phase throughout

- Operator was able to confirm samples contained target fluids, and no further sampling runs were required

- Initial analysis of the samples confirmed the quality of the hydrocarbon discovery, and allowed the client to calibrate logs and improve the accuracy of their dynamic reservoir data

- Client is able to move forward with the next project phase, commence reservoir modeling much sooner than had samples been sent to a conventional lab, which could have delayed the decision making by several months

- Knowing contaminant levels enables earlier procurement of materials for upcoming projects in the area

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU