Case Study

ESP production well diagnosis

Contact

In Brief

Validation of ESP operation and production rate

Product Line

Region

Customer Challenges

- The customer had an Electrical Submersible Pump (ESP) oil well which was producing from multiple zones through the tubing and annulus on one of the largest onshore oilfields in the Middle East

- The customer had a non-return valve (NRV) in place to isolate the tubing and annulus production and prevent well recycling

- The well was expected to be one of the best producers in the field based on the production index (PI)

- The customer was performing routine testing with a trailer-mounted well test separator which identified well and/or ESP underperformance

- Expro was approached to provide additional measurements to help diagnose the well underperformance

Expro Excellence

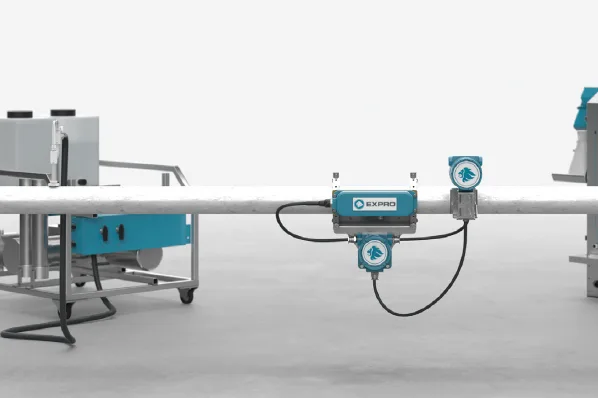

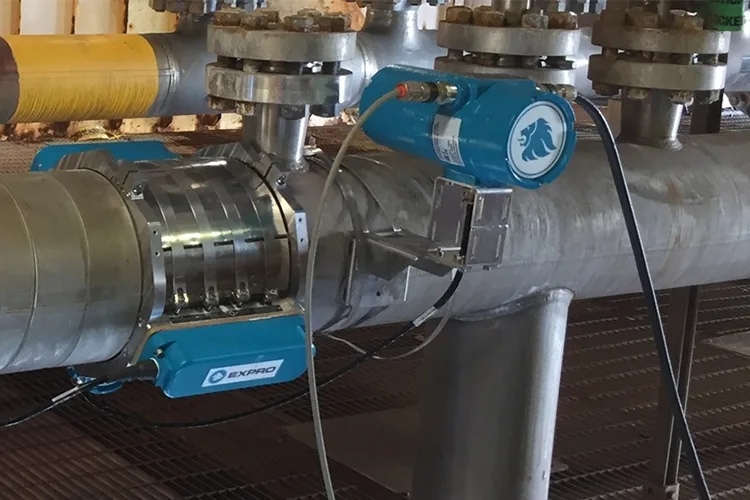

- Expro performed production surveillance using a clamp-on SONAR meter at three discreet measurement locations; tubing, annulus and commingled flowline

- No flow area was detected on the commingled flowline downstream of the choke

- Surveillance on the tubing line upstream of the choke indicated a flow of ~2000 bbls/D while surveillance on the annulus line indicated flow of ~2000 bbls/D however, in the reverse direction

- This clearly indicated that the NRV was not functioning and the well was recycling

Value to Client

- Tested the well at production conditions to verify the separator results and to eliminate any effect of well performance introduced by the temporary rig up of the mobile test separator

- Timely measurement at multiple locations to facilitate quick diagnosis

- Validation of ESP operation and production rate

- Diagnosis of faulty NRV

- Return of well to production after remediation

- Clamp-on SONAR meter was subsequently applied as best practice to underperforming ESP wells with a further diagnosis of four failed NRVs across the field

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU