Case Study

Existing inline metering correction and insight into process conditions

Contact

In Brief

Providing reliable measurements allowing the operator to manage their process efficiently

Product Line

Region

Customer Challenges

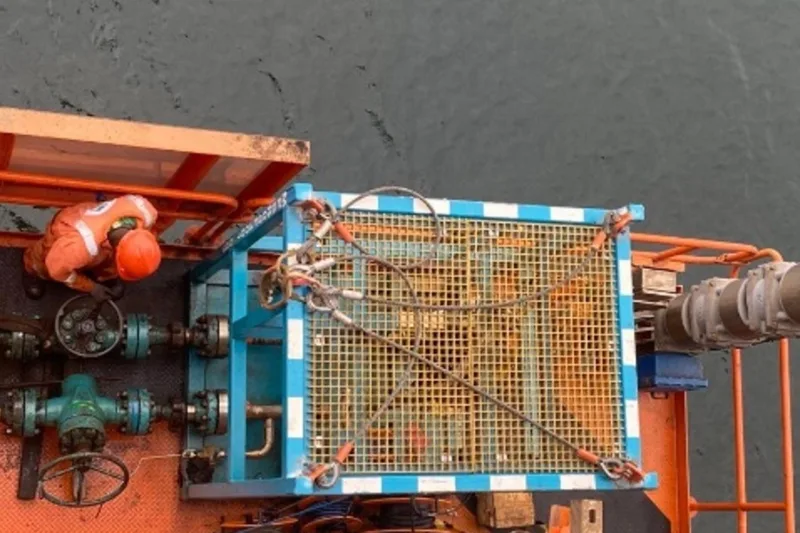

- An operator of an offshore field was measuring flow rates on production separator oil and water outlets across three platforms

- The existing inline metering systems were providing unreliable measurements and prevented the operator from managing their process efficiently

- The customer required non-intrusive but robust solution, which could handle the highly dynamic flowing conditions

- The customer's preference was to continue production, avoid shutdown and resolve the metering issue

Expro Excellence

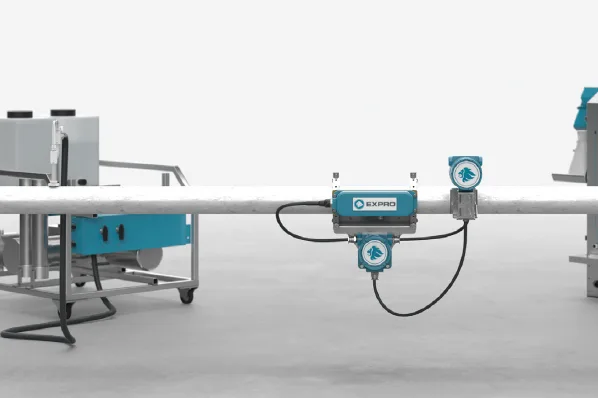

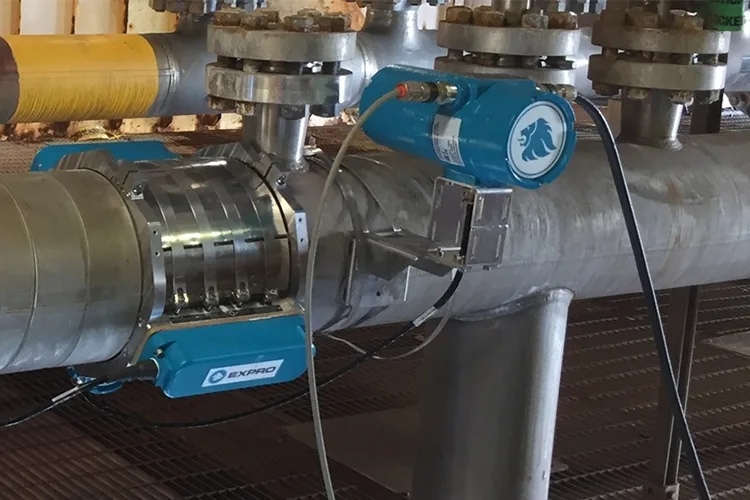

- Expro proposed to use a mobile self contained surveillance package with 3"-12" meter sizes to monitor the separator liquid flow outlets, determine a volumetric rate and establish a gas volume fraction

- Expro's clamp on non-intrusive metering was retrofitted to existing lines without any modifications

- Expro performed 24-hour surveillance with different wells flowing into the separator based on the customer's testing program

- Results were compared to the existing inline metering system

Value to Client

- Expro's diagnostic identified two key issues:

- Slugging was due to a faulty level control valve

- Free gas (GVF) was measured in the single phase liquids, oil and water outlets

- Expro surveillance provided an accurate reference flow rate measurement to identify the error in the existing inline metering

- The customer received insight into the dynamic nature of their process conditions to facilitate a change and bring the process conditions within the working envelope of the existing inline metering

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU