Case Study

From stuck to success: Expro’s innovative pigging solution

Contact

In Brief

Custom pigging enabled safe cleaning of previously "unpiggable" pipeline

Product Line

Region

Customer Challenges

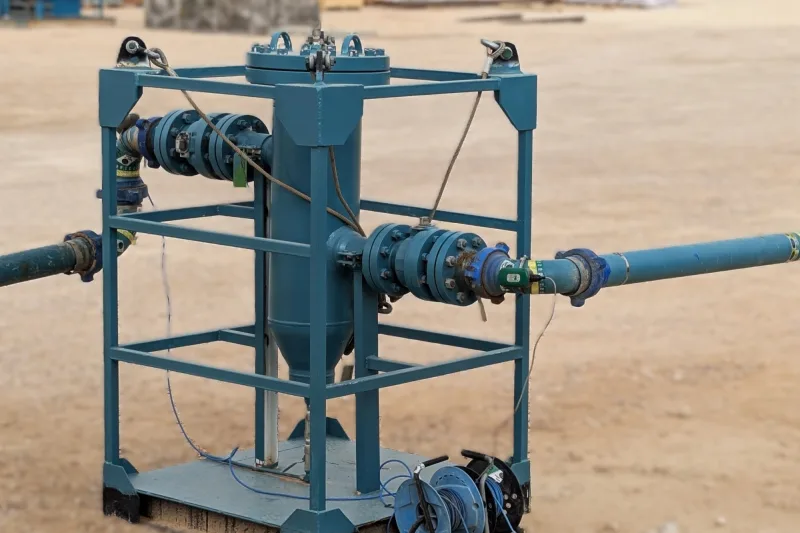

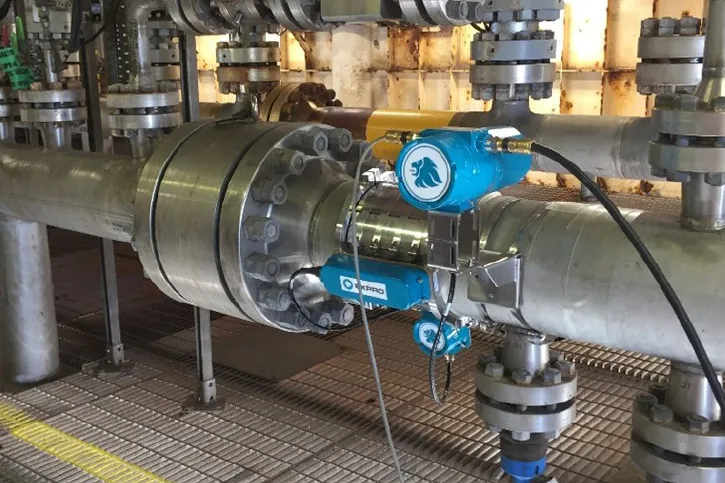

- One of our customers in North America required internal cleaning of a 6 inch pipeline segment that had not been cleaned or inspected for integrity in many years

- All previous attempts at traditional pigging resulted in pigs becoming stuck due to heavy debris and contaminants

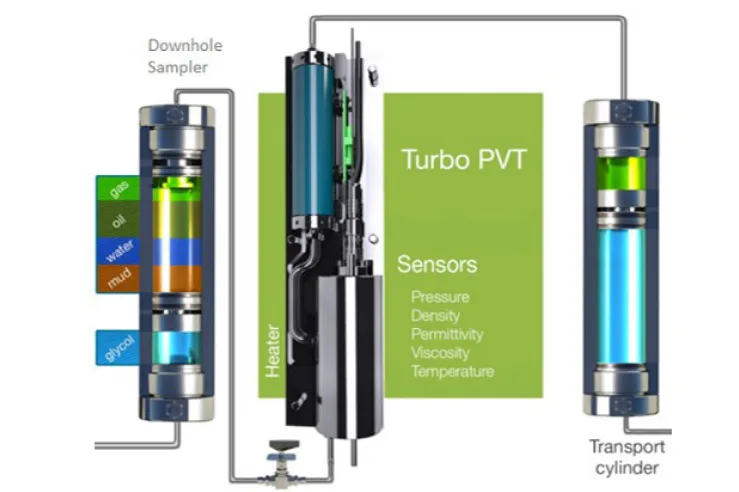

- The pipeline’s condition and contaminants prevented sensor readings, meaning any In-Line Inspection (ILI) smart pig would not generate reliable data

- Without thorough cleaning, any ILI smart pig would likely become stuck, necessitating costly excavation, cut-out, and repair of the pipeline segment

Expro Excellence

- Expro was selected for the project due to advanced mechanical and chemical cleaning techniques

- Engineered and delivered a custom pigging plan with a progressive

approach:- Utilized custom, highly deformable pipeline pigs

- Applied advanced pipeline cleaning chemicals

- Used traditional pipeline cleaning pigs in succession

- Successfully passed over 20 cleaning pigs through the segment previously deemed “unpiggable,” effectively removing debris and contaminants

- Expro’s solution enabled safe, efficient cleaning where all prior

attempts had failed

Value to Client

- Prevented future pig cut-outs, saving the client significant time and cost

- Enhanced pipeline production increasing throughput while decreasing restriction

- Improved the quality of data acquired during the ILI smart pig integrity inspection

- Delivered a reliable, cost-effective solution for a new client, demonstrating Expro’s capability to solve complex pipeline challenges

- The achievement ensured the pipeline was ready for inspection, reducing operational risk and supporting asset integrity

Contact

For further information, please contact pipelineservices@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU