Case Study

Expro provides topside process facilities for 90-day heavy oil EWT

Contact

In Brief

Delivery of a fast-track, best in class EWT in the North Sea where Expro was recognised by the industry and nominated in the Overall Excellence

Category at the UK Oil & Gas Awards

Product Line

Customer Challenges

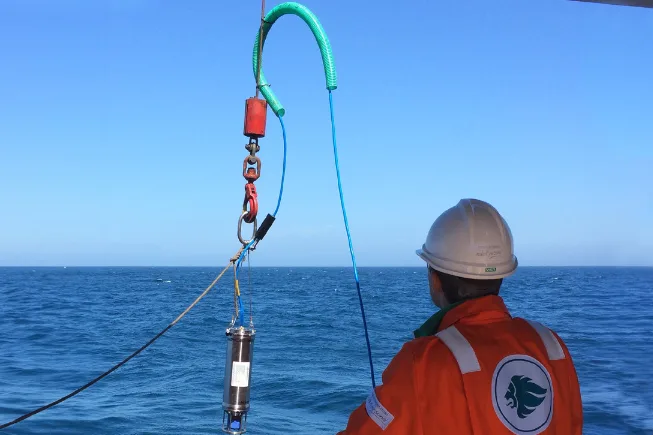

- In order to gain a detailed understanding of the Bentley reservoir and thereby support future field development planning, Xcite Energy planned to carry out an Extended Well Test (EWT). The plan was to flow for a period of 90-days, with temporary process facilities installed onboard the Rowan Norway (DNV Class jack-up rig), and export stabilised crude oil to an offshore shuttle tanker

- Given the heavy nature of the crude oil (10°API), it was important that the test package provided reliable production, as shutdown of the surface facilities or export system could have compromised the objectives and resulted in the end of the test

- In order to minimise the number of control interfaces, and thereby maximise system reliability, the topsides EWT provider was required to take responsibility for integration of their own process safety control system with other service partners contracted by the client during the operational phase

Expro Excellence

- Delivered a fast-track, best in class EWT in the North Sea where Expro was recognised by the industry and nominated in the Overall Excellence Category at the UK Oil & Gas Awards. The EWT topsides scope was awarded to Expro in November 2011 and commissioned for first oil in May 2012

- All project management, engineering and operations personnel were supplied from Expro’s Aberdeen Centre of Excellence for this North Sea project

- Lessons learnt from previous Expro heavy oil / enhanced oil recovery projects were applied to the design, thereby ensuring that the client was not exposed to shut down or loss of production at any point during the test. This was critical, as shutdown of the surface facilities or export system could have compromised the objectives and resulted in the end of the test

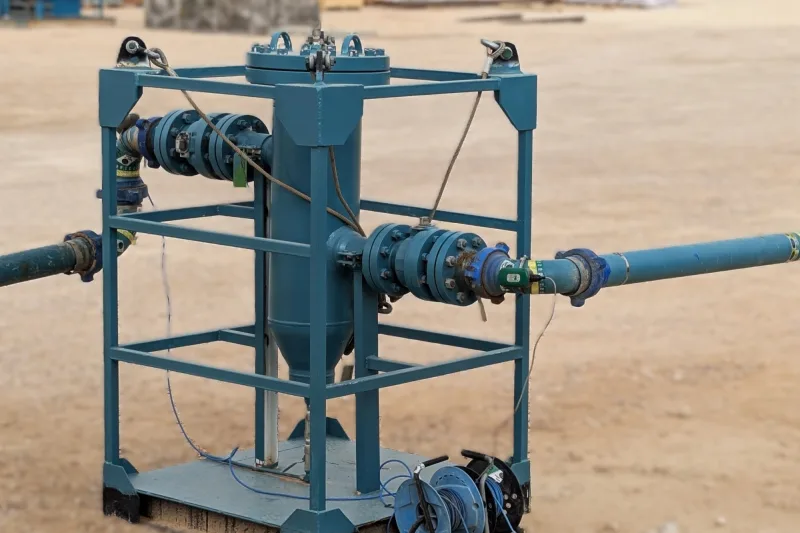

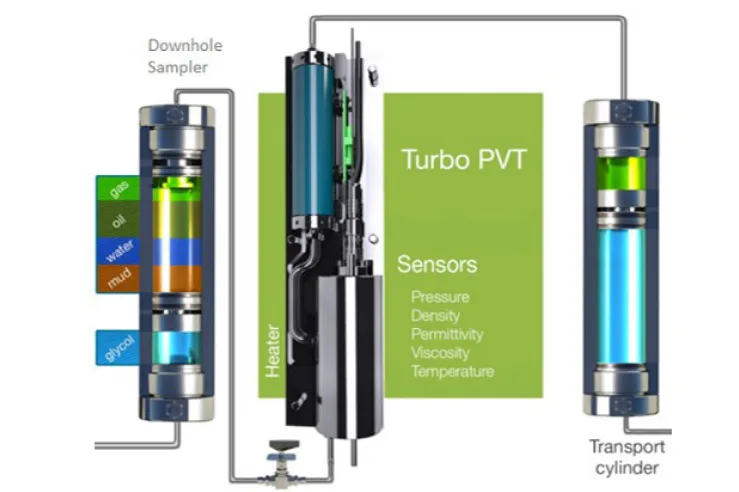

- The main process consisted of inlet heating upstream of the choke manifold, followed by two stages of separation (first 3-phase and then 2-phase) to remove water and stabilise the crude

oil before exporting the ‘dead crude’ to the shuttle tanker - Expro designed, installed and commissioned a fully integrated PLC based control system, which complied with the rig’s safety case and allowed full control of the system - from the downhole ESPs to final export via the shuttle tanker moored 1.5 km from the rig. As the system integrator, Expro took on responsibility for engineering, documentation, installation, and commissioning of the system, all of which was subject to a full DNV audit prior to opening the well

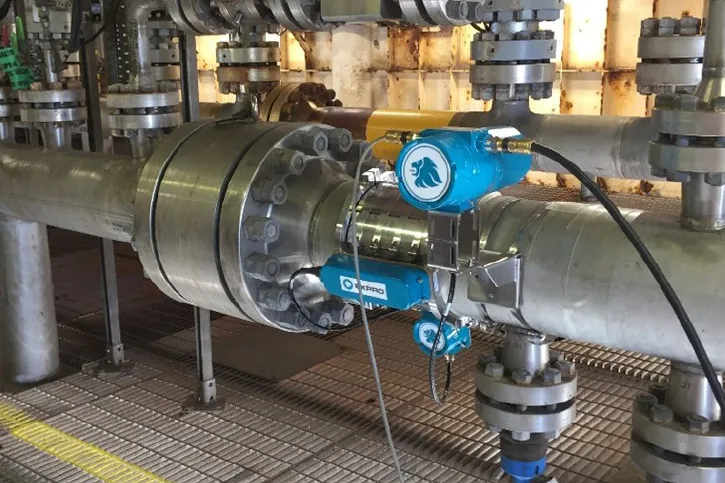

- Expro’s measurement and data acquisition systems were specifically selected for a heavy crude oil with very low GOR. Live data was streamed to personnel onshore, which enabled

the project to be supported real-time from both onshore and offshore; thereby ensuring that the test objectives were met

Value to Client

- By utilising existing assets from inventory and exporting stabilised crude oil, rather than burning it via a well test burner, Expro was able to provide the client with a cost-effective solution whilst minimising its impact on the environment

- More than two months of stabilised crude oil production was exported to market; thereby helping to offset the project costs and allowing the client to meet their commercial objectives

- Valuable data was acquired as a result of the test; thereby ensuring that the client’s field development planning would be based on accurate, good quality information

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU