Case Study

Zero flaring achieved: operational gains through SONAR-based flare gas monitoring

Contact

In Brief

Using Non-Intrusive SONAR Meter monitoring and diagnostics tools to achieve Zero Flaring

Region

Customer Challenges

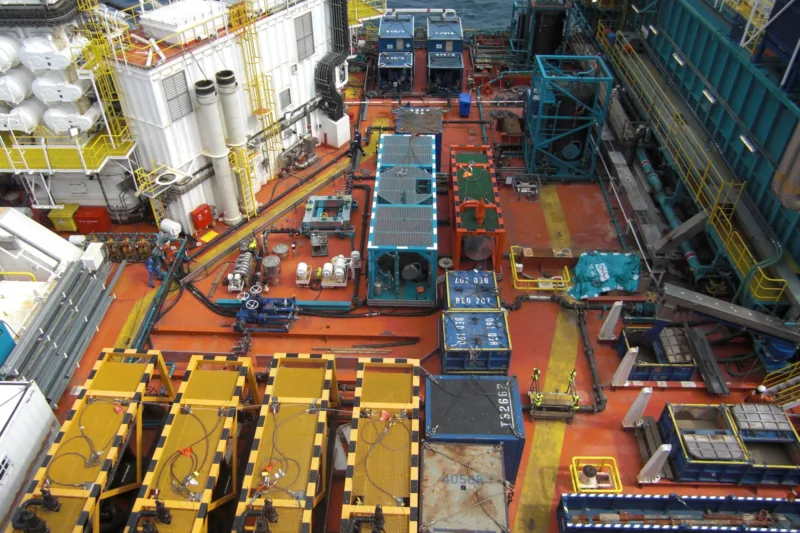

- Oil production facilities in the Middle East routinely flare residual gas as a by-product of oil treatment processes. The client sought to optimize the quantity and quality of this flared gas with the dual goals of reducing environmental impact and enhancing operational efficiency

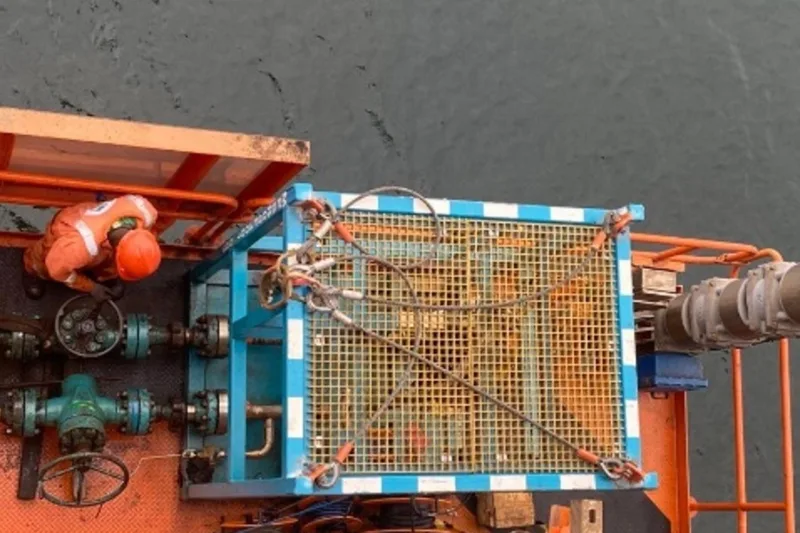

- To achieve this, the operator installed a specialized gas compressor to capture and divert flare gas for power generation downstream. However, effective optimization required accurate, continuous gas flow measurements across the facility

- Traditional inline flow measurement was ruled out due to the high operational expenditure (OPEX) and complexity of installation. Furthermore, process data showed fluctuating gas compositions and unstable readings over 24-hour cycles

Expro Excellence

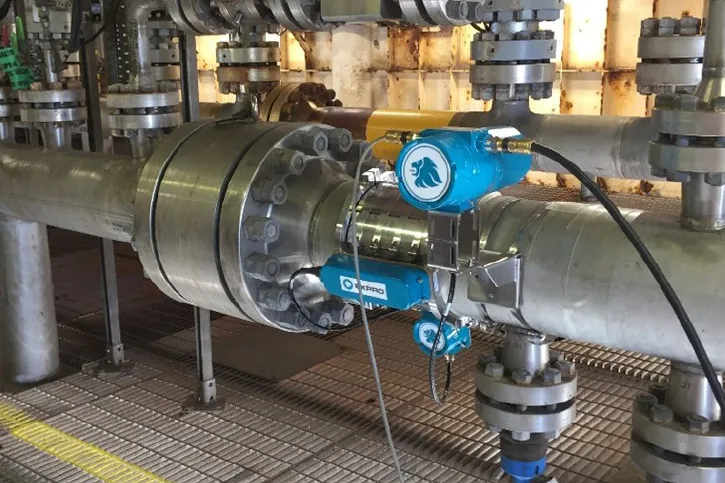

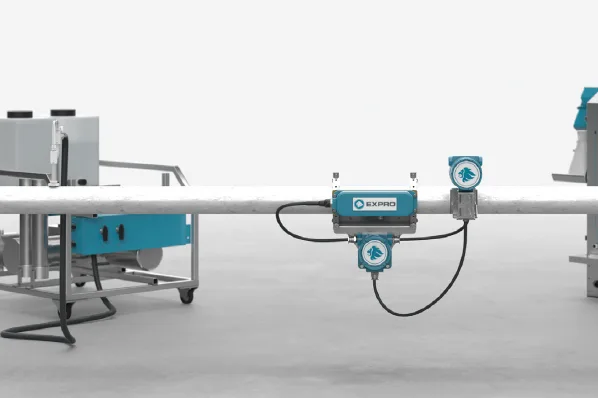

- Expro proposed the deployment of non-intrusive SONAR Meters, recognized for their ability to reliably measure low-pressure gas flows - even in the presence of wet gas - without the need for costly inline installation

- A testing program was initiated involving eleven test points on flare and process gas lines, with pipe sizes ranging from 8 to 16 inches

- The SONAR Meters successfully captured gas flow rates and the Speed of Sound (SoS) within the gas medium over 24-hour monitoring periods

- Diagnostic data and SoS trend analysis revealed nighttime liquid dropout due to temperature drops, directly impacting flaring volume

Value to Client

- Achieved Zero Flaring: The implementation of SONAR Meters enabled the operator to eliminate routine flaring, significantly reducing environmental impact

- Emission Reduction: By recovering flare gas, the facility reduced annual CO₂ emissions by an estimated 70,000 tons

- Enhanced Gas Production: The total flare gas recovered from the facility was 2.5 MMSCF/D which was then redirected for treatment and commercial sale

- Operational Insight: The diagnostic capability of the SONAR Meters identified liquid presence within gas lines - information crucial for optimizing compressorperformance and preventing

potential operational issues

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU