FloatCure®

FloatCure® is the only buoyant cementation system. FloatCure® combines the power of buoyancy to reduce torque and drag with full run-in-hole circulation capability, ensuring casing is landed at target depth.

Buoyant Cementation

Horizontal or extended reach wells are expensive and can be challenging to drill, but they often have a number of benefits to the operator. Traditional casing floatation techniques do not offer circulation; therefore, it is not possible to wash the casing down with buoyancy or complete the cement job.

Expro's FloatCure® is the only solution offering net effective weight reduction of a casing or liner string with full circulation at all times throughout the entire run in hole operation and cement job. FloatCure® can be utilised in any well whether subsea, platform or land.

Buoyant cementation with FloatCure®

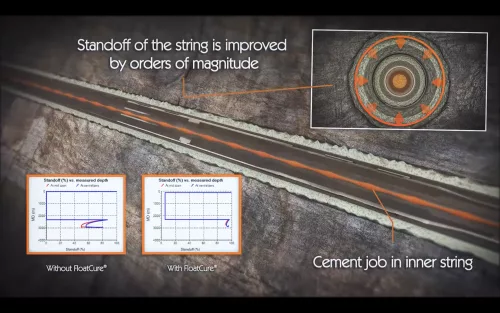

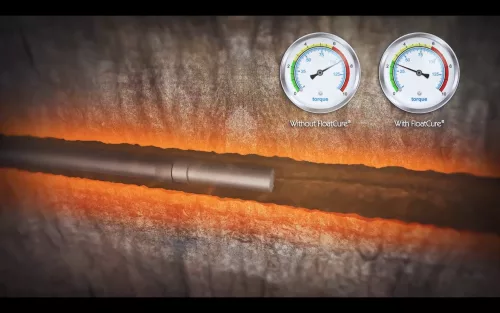

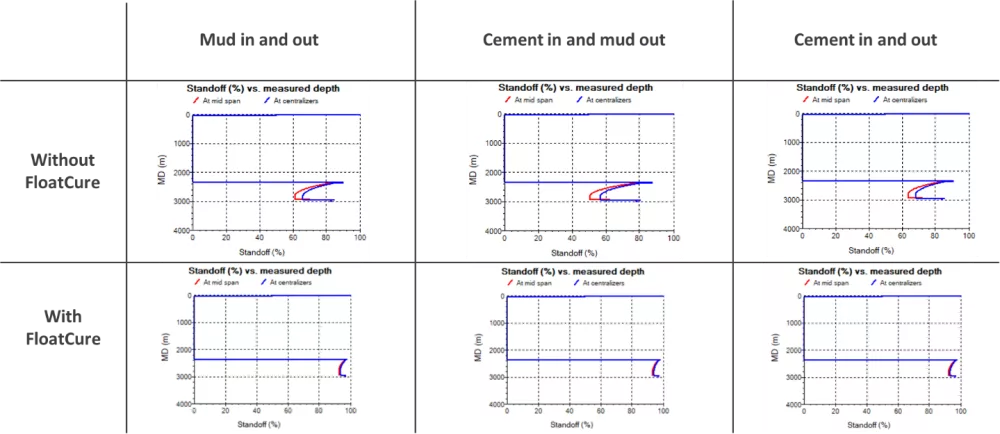

Enabled by Expro's proprietary and field proven SeaCure® technology, FloatCure® harnesses the power of buoyancy to reduce the effective weight and corresponding torque and drag of the string being cementing, ultimately improving its standoff and the overall quality of the cement job.

FloatCure® technology delivers a new level of cementing reliability by maximising the use of casing and liner buoyancy, drastically improving casing standoff whilst reducing hook-load and torque & drag by up to 80%. FloatCure® can enable the deployment and cementing of otherwise un-runnable or un-rotatable liners.

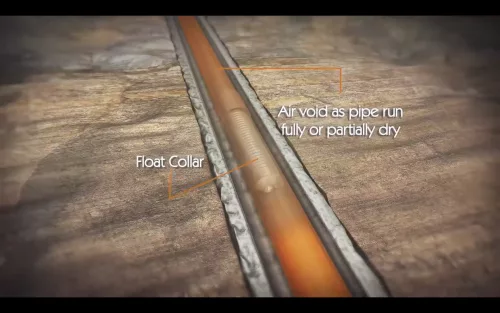

At the rig floor, a casing or liner is run with a SeaCure® float shoe or float collar. The collar consists of dual floats, with a wiper plug receiver and drill pipe latch-in receiver complete with back-up release shear out feature. Critically, the liner is run either entirely or partially dry to provide buoyancy for the system.

By deploying the casing string either partially or entirely dry during make-up, followed by the SeaCure® inner-string technology, a buoyancy chamber is maintained at all times during the run-in-hole and cementation process, facilitating the industry’s only technique of influencing net effective weight of a casing being circulated to depth and then cemented.

FloatCure® can be utilised with any liner hanger system, which will influence the ultimate operational sequence for setting the liner and subsequent pressure testing.

FloatCure® provides major key benefits while extending your reach through reducing the system net effective weight. However, unlike conventional buoyancy-assist floatation equipment, FloatCure® maintains buoyancy and pump-through capability for the casing/liner system throughout the entire running and cementing operations.

This differentiation means that, only FloatCure® can provide critical well cleaning and optimal cement placement whilst rotating the liner, significantly improving stand-off of the string. All of these benefits are delivered utilising simple, reliable and field-proven technology.

FloatCure® Value

- Access stranded hydrocarbons from existing infrastructure

- Deliver wells with fewer sections, saving rig time, cost and carbon emissions

- Dramatic reductions in torque & drag whilst running in hole

- Ability to circulate the buoyant string to depth at all times

- Ability to rotate the buoyant string during cementing

- Significant improvement in standoff during well cleaning and cementation

- Reduction in differential sticking risk

- Reduced circulation, losses and displacement volumes

- Improved drill out performance with minimised damage to drill bits and BHAs

- Reduced swarf quantities introduced into the wellbore

- Increase capacity of lower graded rigs derricks

Datasheets

Get in touch

Contact FloatCure®

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU