Case Study

QPulse™ Revolutionizing Production testing with non-intrusive Multiphase Flow Measurement

In Brief

QPulse™ enabled accurate, non-intrusive multiphase flow production testing at 65% Gas Void Fraction and high water cut

Product Line

Region

Customer Challenges

- A customer in the Middle East was seeking a non-intrusive solution to accurately test production flow rates for unconventional wells

- The field was producing critical oil with a high water cut and a Gas Void Fraction (GVF) ranging from 65% to 75%

- A high turndown testing solution was required, with minimal pressure drop, alongside the capability to measure a wide range of liquid production rates. This was essential to identify potential liquid loading and water influx in individual wells

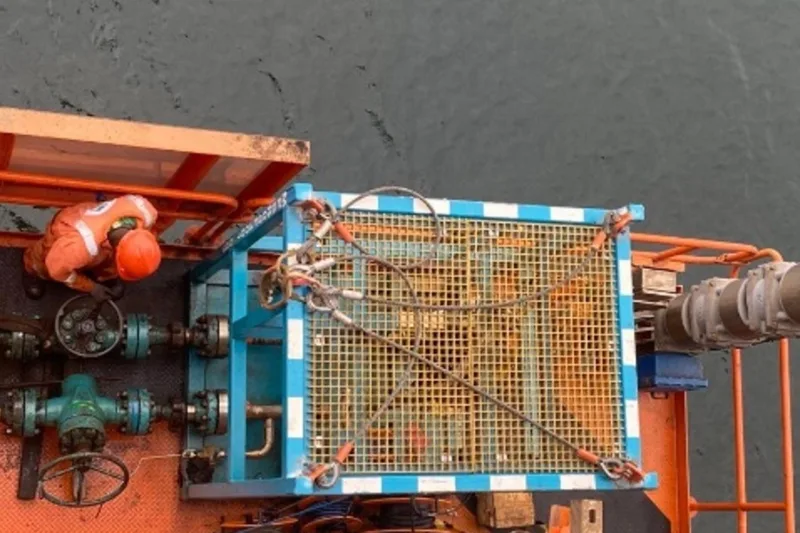

- The solution needed to be operational even on remote wellheads with limited access

Expro Excellence

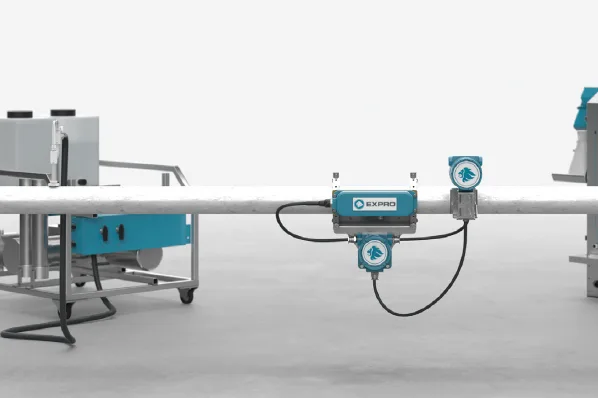

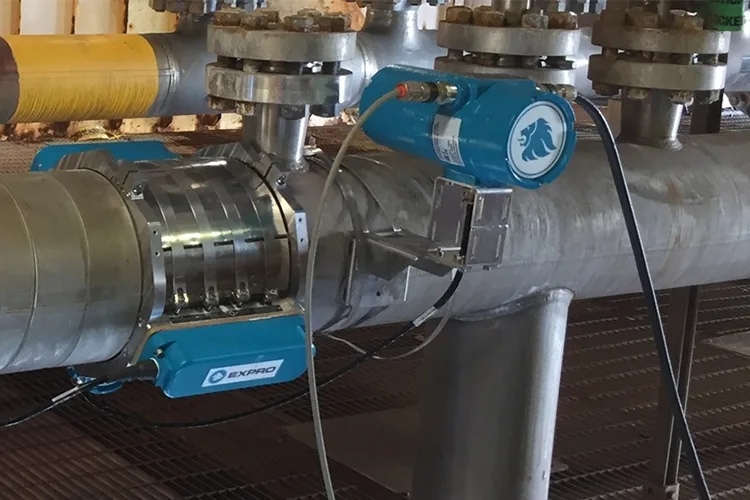

- Expro provided its QPulse™ solution, a non-intrusive, portable multiphase flow surveillance system that integrates proprietary SONAR clamp-on technology with MultiTrace® technology

- SONAR Technology: The Expro SONAR Meter effectively operates in multiphase flow, offering a total volumetric flow rate and accurately measuring gas flow

- MultiTrace® Technology: This system directly measures condensate and water flow rates, utilizing a non-radioactive tracer dilution technique for precise results

- The use of QPulse™ enabled testing at actual flowing conditions without any production interruption. The data gathered was compared to conventional test separator data as part of the field setup, ensuring consistency and accuracy

- Key parameters like Gas-to-Oil Ratio (GOR2) and shrinkage were measured onsite as part of the standard QPulse™ dataset, enabling accurate reporting of both total and “separator” gas

Value to Client

- Direct, Accurate Measurements: QPulse™ provided precise and independent measurements for gas, condensate, and water rates, eliminating the need for PVT or water cut computations

- Enhanced Production Profile Understanding: The solution gave the client vital data to better understand the production profile of the assets

- Lower Carbon Footprint: QPulse™ is a compact, mobile solution, resulting in a reduced environmental impact compared to traditional testing methods

- Proven Performance: The technology was validated during pilot testing against a test separator, meeting key performance indicators (KPIs) with an accuracy of within 5% for gas, oil, and water measurements

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU