Case Study

SONAR Meters Deployment on Dual Phase Trunk Lines for Flow Assurance and Leak Detection

In Brief

Expro’s ActiveSONAR™ delivered real-time accurate measurements for dual phase trunk lines, enabling production assurance and remote monitoring.

Product Line

Customer Challenges

- The customer was sourcing for a suitable flow metering solution to enable them to carry out accurate real time measurements at remote locations along their liquid export pipeline

- There were concerns on the regular downtime during operations due to several leaks which necessitated a metering solution that could help detect leaks in a timely manner and deliver production assurance

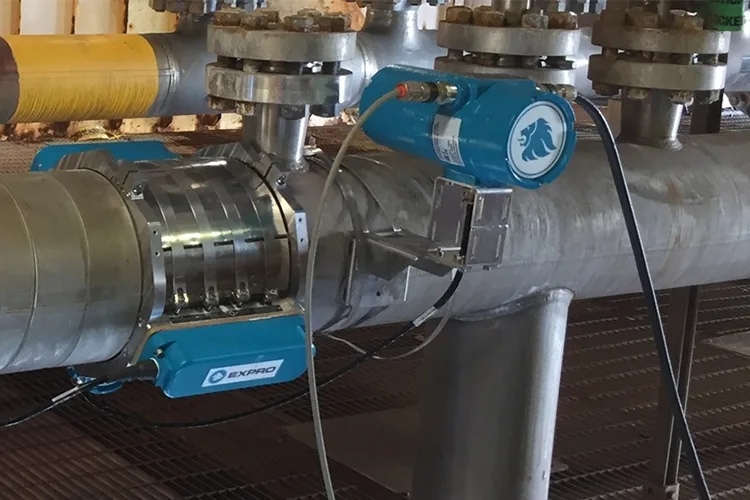

- Customer opted to avoid breaking containment to install an inline meter due to expected high NPT, HSE risks and cost of installation on large pipe sizes such as 24inch and 28inch

- Customer previously tried installing standard industrial clamp on meters on the flow line, but their performance was unsatisfactory due to multiphase nature of the fluids

- The Liquid export line contains oil and water with entrained gas. Water cut was dynamic, ranging from 10% to 30% during the meter commissioning

Expro Excellence

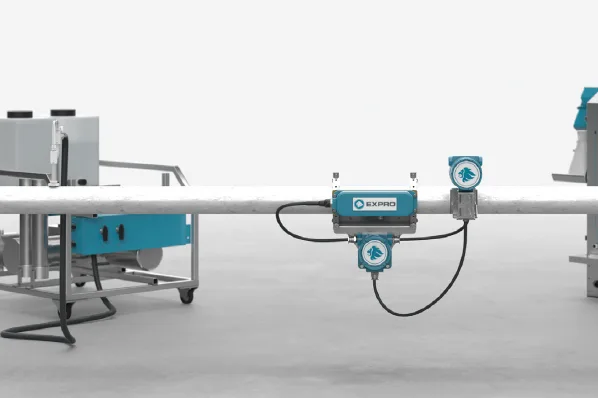

- Expro’s ActiveSONAR™ flow meter was proposed to the customer

- Technology was evaluated through a pilot program against an existing Coriolis Meter to verify the accuracy/ performance of the ActiveSONAR™ Meter

- Pilot test was successfully completed with SONAR Meter uncertainty within +/-2% of the existing Coriolis Meter

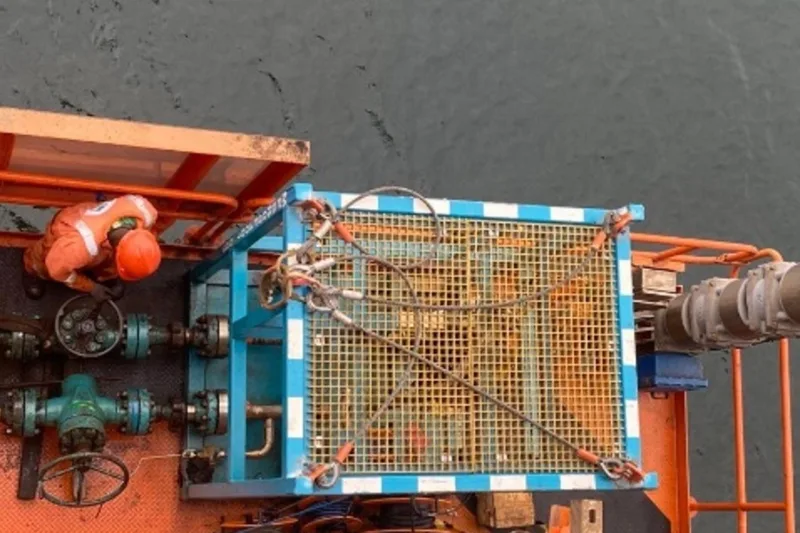

- Customer subsequently deployed 6x ActiveSONAR™ Meters of sizes varying from 10inch to 28inch to be installed at the inlet and outlet of each trunk line

- Installation and commissioning of the 6x SONAR Meters inclusive flow computers for real time data transmission was successfully completed on an expedited timeline

- Expro earned a 100% Job Performance score for outstanding execution across all sites

Value to Client

- Expro delivered a non-intrusive solution with no disruption to ongoing production

- Due to ActiveSONAR™ Multiphase tolerance, diagnostic data allowed the customer to identify changes in flow regime and process issues and highlighted its impact on production assurance

- Customer utilised the SONAR Meters capability to transmit data in real time through a satellitebased data transmission system allowing them to view real time performance of the meters at remote locations

- Based on the success of the project and the data quality, customer plans to deploy ActiveSONAR™ Meters across their entire crude export pipeline network

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU