Case Study

Temporary facilities provide a boost to production

Contact

In Brief

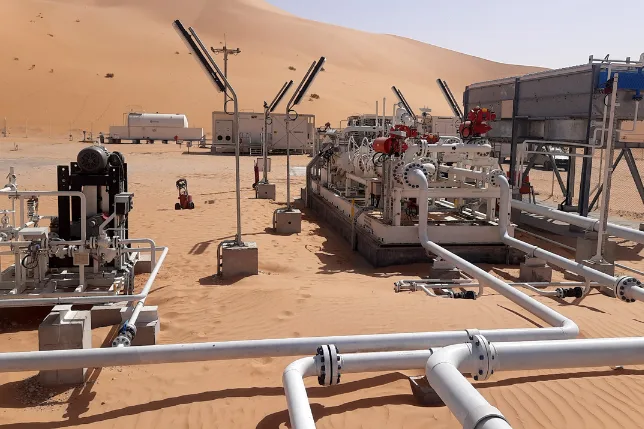

Expro supplies a temporary modular facility on a lease, operate and maintain basis, which allowed the client to increase production pending upgrades to its permanent flow station

Product Line

Customer Challenges

- The client was looking to increase production from their existing flow station but were experiencing delays in the bidding and contract award process for a permanent upgrade to their facilities

- The temporary facility was intended to be operated and maintained until the installation and commissioning of the permanent process facility were completed

- The safety challenges associated with Simultaneous Operations (SIMOPS), specifically the installation of the permanent facility while continuing hydrocarbon production via the temporary facility

- Remote location - the site presented difficult terrain, thereby complicating access and equipment installation

Expro Excellence

- Due to Expro’s experience with providing early production facilities and strong QHSE performance, we were chosen to deliver a fast-track production upgrade using existing in-country process facilities

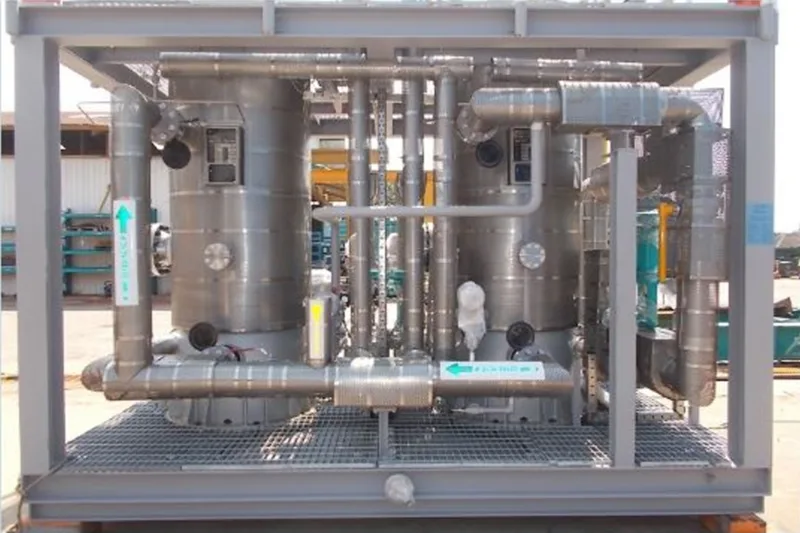

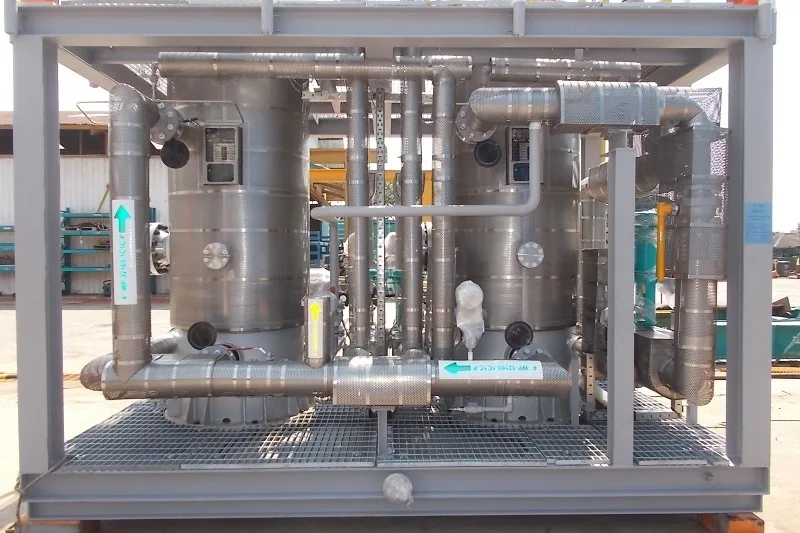

- Expro mobilized and installed an existing well-testing package that was configured such that additional equipment could be tied in to continue production at increased rates of up to 5,000 bpd

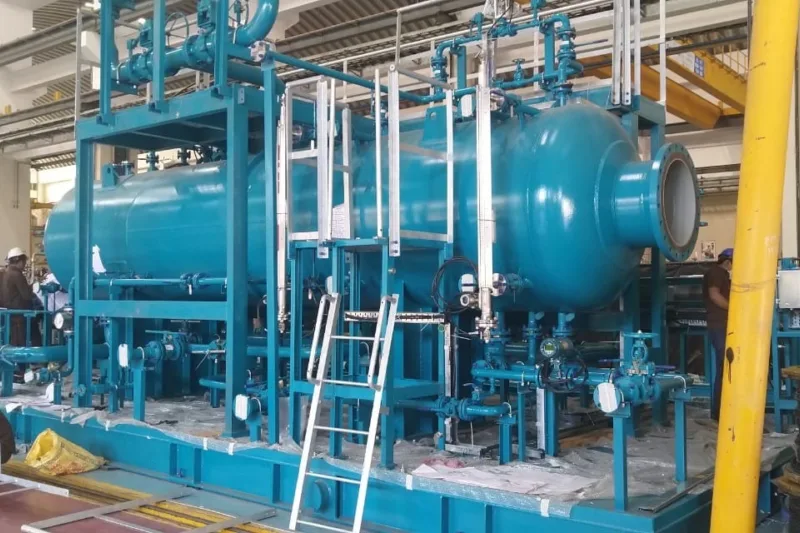

- Expro’s solution comprised an inlet heater with a dual coil, facilitating pre-heating of flow diverted from the existing facility to enhance separation efficiency

- Stabilized crude oil was transferred into the client’s tank farm, from where it was finally pumped into the Oziengbe/Oredo export Line

- Due to the continuous, 24/7 operational period, an automated pumping system was implemented to monitor and control tank levels without requiring constant manpower intervention. This measure effectively prevents liquid carryover to the flare or gas blowby to the client’s storage tanks

- The equipment was integrated into the existing flow station and supplied on a lease, operate and maintain basis, pending completion of the client’s permanent upgrade to their flow station

- The facility has maintained continuous operation with >99% uptime and availability since the start-up

Value to Client

- Although there were delays in the contracting process for a permanent upgrade, Expro successfully implemented a temporary fast-track solution, enabling the client to boost production

- The installation of the temporary equipment was meticulously engineered to ensure it did not interfere with the preparation of foundations and the installation of the permanent facility, thereby maintaining excellent safety performance during SIMOPs

- The piping between the process equipment and production manifold was strategically engineered and designed to minimize production suspension when transitioning from the temporary

- equipment to the permanent facility, thereby optimizing uptime and maximizing production and cash flow for the client

Contact

For further information, please contact production@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU