Case Study

Reinstating instrumentation in production observation wells

Contact

In Brief

CaTS gauges replace failed permanent gauges to provide critical data for production optimisation in the Middle East

Product Line

Region

Customer Challenges

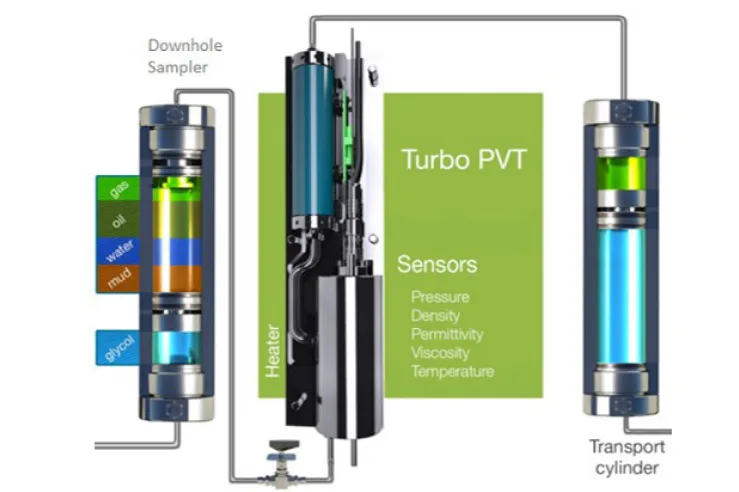

- A major operator located in the Middle East had previously drilled and instrumented a series of production observation wells. These wells are essential for providing reservoir performance updates, however over time many of the permanent cabled gauge systems had failed

- Our customer needed to continue gathering subsurface pressure data from these observation wells in real time in order to develop optimal production and injection strategies for the field

- A key driver here was to re-instate this monitoring in the most cost effective way

- Performing a well workover to deploy new cabled gauge systems wasn't deemed as a cost effective solution

- Collecting pressure data using memory gauges requires frequent intervention operations, which also adds time and cost overhead for gathering this data

- Memory gauges only provide access to historic data and therefore the operator is unable to make dynamic decisions based on this data. This can have a negative impact on production, particularly during high demand periods

Expro Excellence

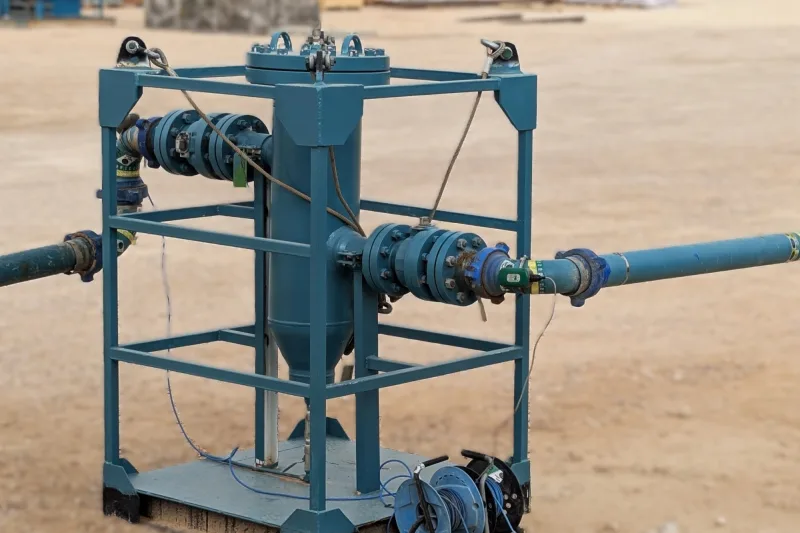

- 23 CaTS Gauges were installed in onshore production observation wells using standard slickline operations

- To set the gauges into the wells, wireline lock mandrels were attached to the top of the gauges and these locked the gauge assemblies into the existing X nipple profiles

- Seven of the wells did not have suitable nipple profiles to set the gauge in and so we implemented a novel and cost effective solution. This involved soft setting gauges on top of standard mechanical tubing stops

- Across the 23 gauge installations, the gauge setting depths ranged from 4500ft to 5700ft with relatively low downhole temperatures

- CaTS surface receivers were installed at each location and successfully interfaced to the existing onsite communications network to provide a data-to-desk service

- The Gauge data transmission schedules were programmed to deliver one data point every 14 days with a downhole battery life expectancy of 3+ years, before requiring a wireline intervention to replace batteries

Value to Client

- All 23 systems were installed and commissioned successfully, providing valuable reservoir surveillance data, which was not previously accessible

- This is another example where CaTS retrofit wireless gauges were a cost effective solution for reinstating downhole monitoring. The solution did not require the high cost of performing a well workover to install a new cabled gauge system

- The ability to access accurate reservoir data from these production observation wells is extremely valuable to the subsurface team, as it allows successful management of the reservoir and enables the operator to optimise production and injection strategies for the field

Contact

For further information, please contact ExproSES@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU