Case Study

Fast-track Early Production Facility for Middle East operator

Contact

In Brief

Expro deliver fast-track Early Production Facility for Middle East operator within 15 weeks to enable early oil production

Product Line

Region

Customer Challenges

To enable production of oil, from previously tested wells, for an operator's field in Kurdistan

Expro Excellence

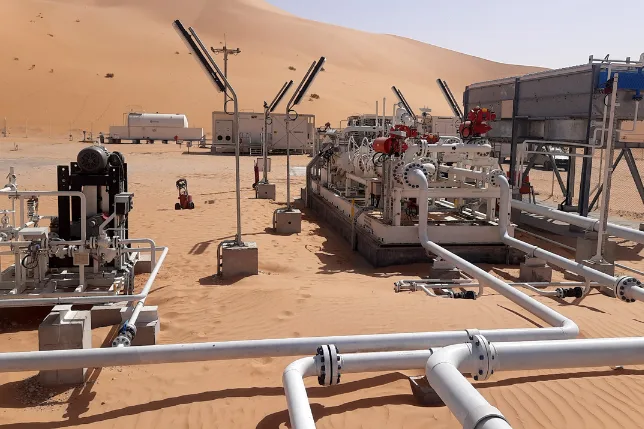

- In response to delays with civil works, construction, fabrication and commissioning, Expro were challenged to adapt plans for an Early Production Facility (EPF) into a fast-track Temporary Production Facility (TPF)

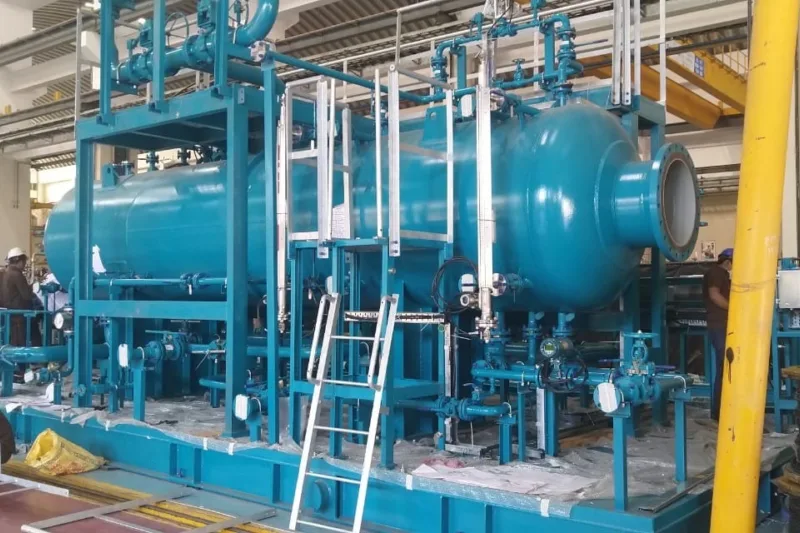

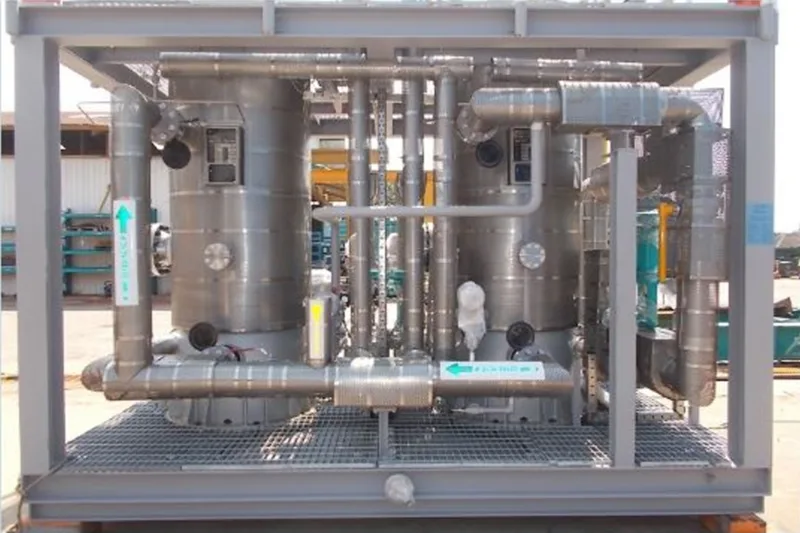

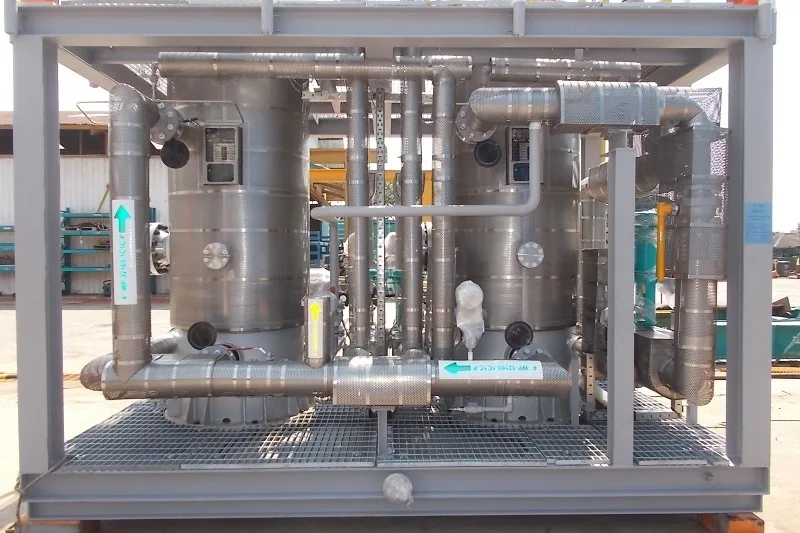

- Production equipment provided included: surface safety valves; indirect (dual fuel) heater; choke manifold; horizontal separator; surge tank; transfer pumps; vertical flare stack; and stack-match ignition system

- The EPF was constructed within 120 meters of the TPF location

- The TPF was sourced from existing inventory equipment, configured offsite and required minimal construction of site piping and ancillaries

- The testing package was set up on one well pad, with the effluent then produced via the package into onsite large capacity storage tanks, then pumped onwards to the tanker loading station (9 km away)

- Expro's flexible and proactive approach facilitated a smooth transfer between their equipment, client-owned storage tanks and loading station, and third party vendors

Value to Client

- The implementation of the TPF enabled the client to collect real-time production data to appraise reservoir performance, which in turn facilitated optimal design of their more permanent/long-term facility

- The EPF site was prepared and located 150 meters from the well site and 500 meters from the pipeline - a truck tanker loading station with initial capacity of 10,000 bbl/d was also constructed 9.5 km from the EPF near the main highway to facilitate domestic sales

Contact

For further information, please contact production@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU