Case Study

CaTS retrofit wireless monitoring system delivers real-time data-to-desk to optimize water injection

Contact

In Brief

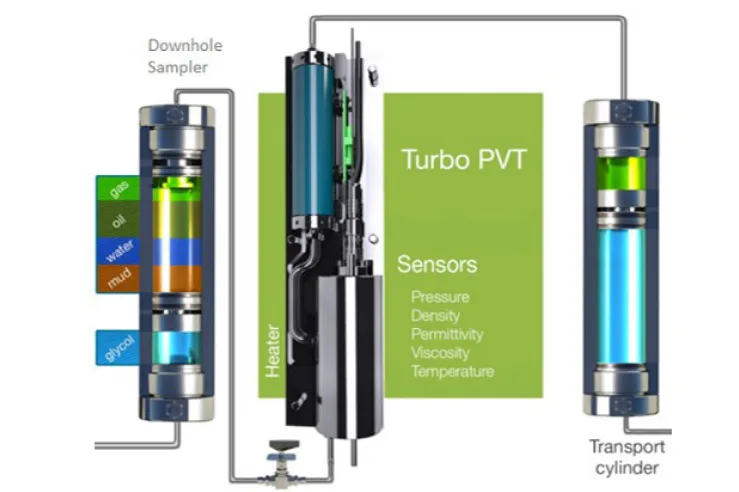

Using downhole wireless gauges to optimize field injection operations

Product Line

Region

Customer Challenges

- Our customer operates a large offshore platform with several producer and injector wells

- There was a requirement to obtain real-time pressure and temperature (P&T) data for a minimum of one year from a water disposal well that did not have any existing downhole gauges

- It is necessary to understand the pressure transmissibility at different disposal rates to de-risk the current injection scheme on the platform, and continuously monitor the UER pressure for anomalies or evolution

- Memory gauges or slickline surveys could not be used as they required frequent well interventions, and this would not provide real-time data

- Performing a well Workover to install a conventional cabled permanent downhole gauge was outside of the budget and timeframe

Expro Excellence

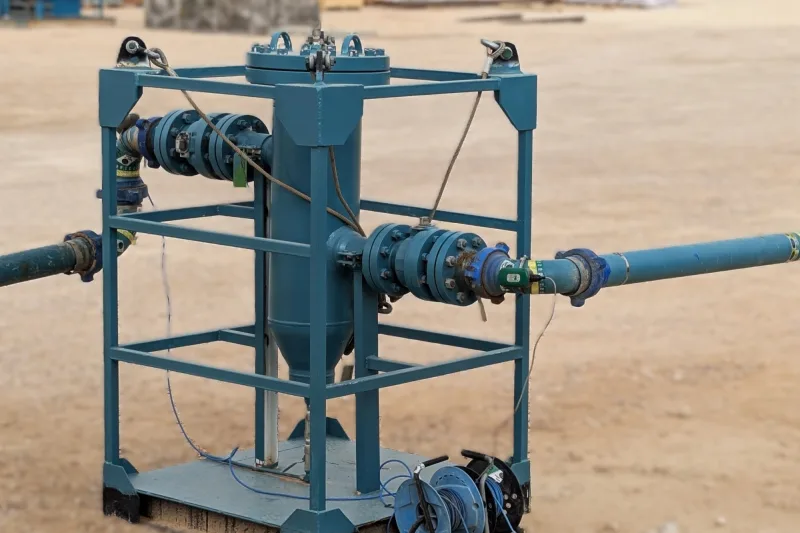

- Expro performed a topside and in-well survey to accurately assess the environment and operating envelope of the system. This allowed the optimisation of data transmission settings

- The casing was powder coated, which can impact the local wireless signal coupling. We designed a solution to optimise the EM contact without impacting the deployment

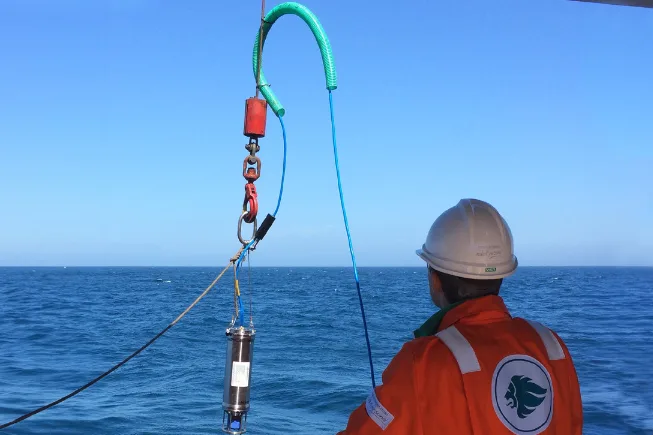

- This was an integrated project using our Wireless Well Solutions and slickline services, where the gauge was run using standard slickline, during a routine intervention campaign

- The CaTS gauge was set at 442 ft and programmed with multiple schedules to meet the data objectives and system life requirements

- A high-expansion gauge hanger was used to set the gauge, which allowed flexibility with the setting depth

- Expro demonstrated excellent communication skills in dealing with multiple stakeholders throughout the project

Value to Client

- The customer was able to meet their objective for receiving wireless real-time data-to-desk from their water disposal well

- CaTS data is being used to optimize and derisk injection regimes on the platform and in the field, and provides continuous monitoring of the candidate well

- The gauge is retrofittable and retrievable using slickline, meaning the batteries can be easily replaced to extend the monitoring duration. The gauge can then be redressed and redeployed in other customer once the data objectives have been met, providing a cost-effective and long-term monitoring solution

- The wireless data was interfaced directly into the existing SCADA system installed on the platform providing data-to-desk access

Contact

For further information, please contact wireless@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU