Case Study

CaTS gauges deployed for asset integrity monitoring

Contact

In Brief

Deploying CaTS downhole wireless gauges to monitor dynamic pressure relief of an IBO (Internal Blow Out) Well System for our customer in South East Asia

Product Line

Region

Customer Challenges

- Our customer in South East Asia had a complex oil and gas field located offshore in water depths up to 45m

- The reservoir was highly compartmentalised and consisted of intermediate and deeper high-pressure gas zones that had the potential to charge shallower less competent oil reservoirs and cause subsurface internal blowouts

- To solve this problem a system of 20 Internal Blow Out Monitoring wells were developed specifically for pressure relief and monitoring of the blow-out affected reservoirs

- This well system was developed from converting the use of production wells, which had varying degrees of monitoring instrumentation available for use

- Some of the wells had existing PDGs that were still working but most of the monitoring was achieved by performing regular wireline interventions with memory gauges every 3 months

- Scheduling work around monsoon periods, combined with the ability to access remote platforms and juggling intervention priorities made the well surveillance strategy very challenging

Expro Excellence

- Discussions took place with the local Production Technology team to evaluate options to retrofit CaTS gauges into various IBO Monitoring wells and deliver data-to-desk in real time

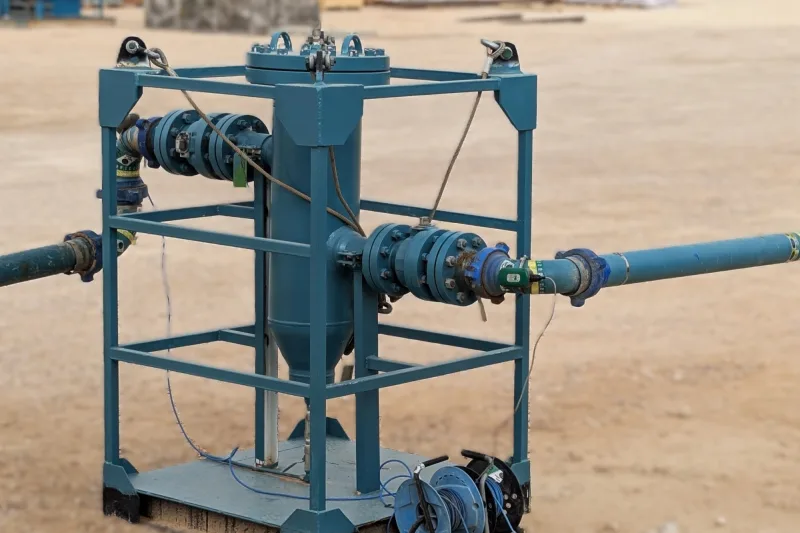

- Well parameter information was obtained, and offshore surveys were conducted on the Normally Unmanned Installations (NUI) to determine suitability of deploying the CaTS technology

- Expro developed a new type of signal detection method specifically for small offshore fixed platform installations, which provided EM background noise cancellation for the CaTS surface receiver panel

- Having identified several candidate IBO monitoring wells for CaTS, the customer purchased three complete wireless gauge systems

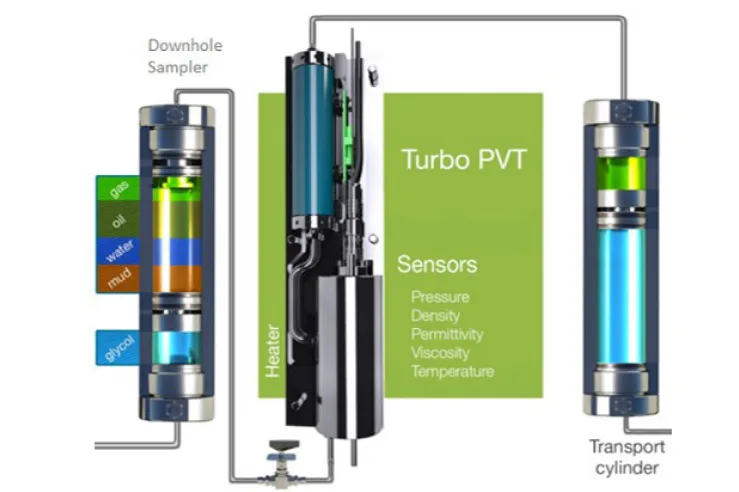

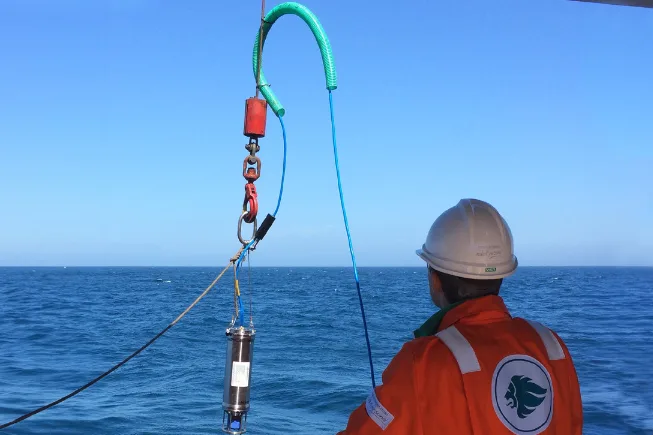

- CaTS Gauges were retrofitted into the well using standard slickline equipment and real time reservoir pressure and temperature data was successfully transmitted to surface

- The depth of the gauges varied between 1400m and 2200m without the need for in-well repeaters

- Gauges were configured to transmit a pressure and temperature data point every 3 days for 2 years. A standard slickline operation is then performed to replace batteries in the downhole gauge

Value to Client

- CaTS Gauges were successfully installed to reinstate downhole monitoring in offshore wells on a Normally Unmanned Installation

- Having access to real-time data allowed the dynamic management of the IBO wells system an ensured production optimisation whilst maintaining integrity of the producing reservoirs

- The number of interventions required on the Normally Unmanned Installation are reduced, saving cost, reducing operational risks and lowering the operational carbon emissions for the client

- Retrofitting CaTS Gauges provides the customer with a cost effective and flexible solution to retrieve and re-deploy real-time downhole monitoring as and when required

Contact

For further information, please contact wireless@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU