Case Study

Accelerated Production Solution provided customer with early cash to finance long term project

Contact

In Brief

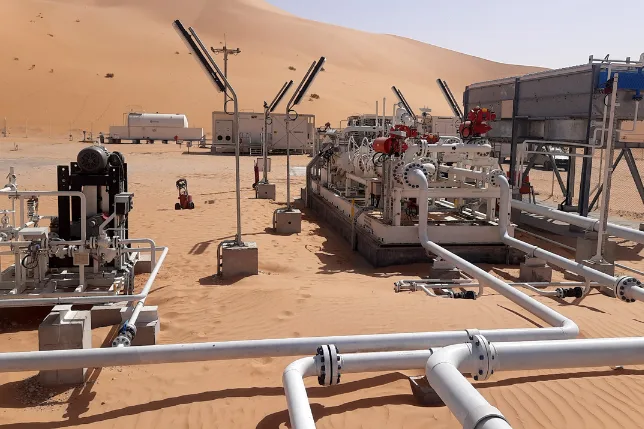

Expro mobilized and installed a well testing package that was configured such that additional equipment could be tied-in to continue production at increased rates of up to 10,000 bpd once the well test was complete

Product Line

Customer Challenges

- An independent operator in West Africa needed to generate early cash to fund investment in its long-term production facilities

- The Regulatory body requested well performance data before authorizing the start of commercial production

- The temporary facility was to be operated and maintained until the permanent process facility was installed and commissioned

- The safety challenges associated with SIMOPS – i.e. installation of the permanent facility whilst continuing to produce hydrocarbons via the temporary facility

- Remote location: Difficult terrain to access the site and then install equipment

Expro Excellence

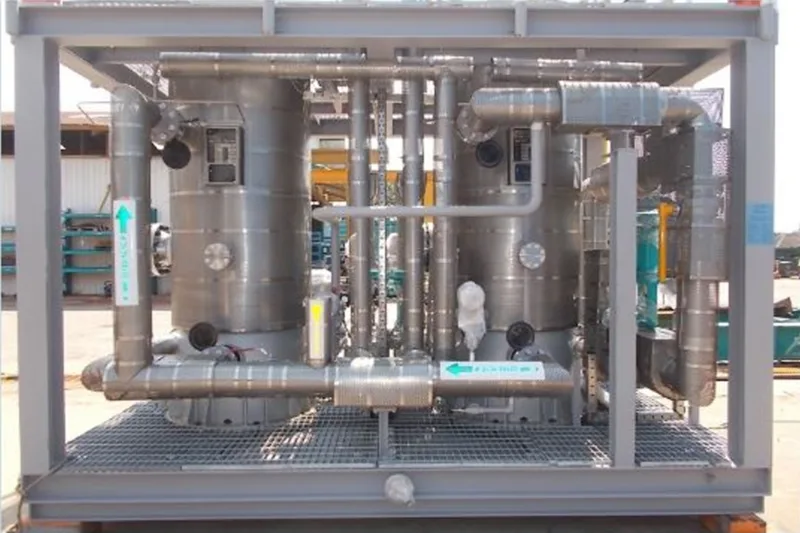

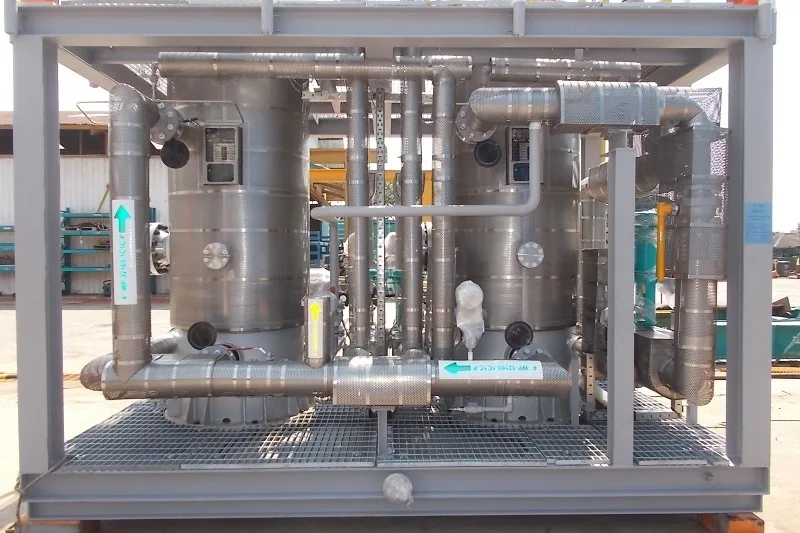

- Expro mobilized and installed a well testing package that was configured such that additional equipment could be tied-in to continue production at increased rates of up to 10,000 bpd once the well test was complete

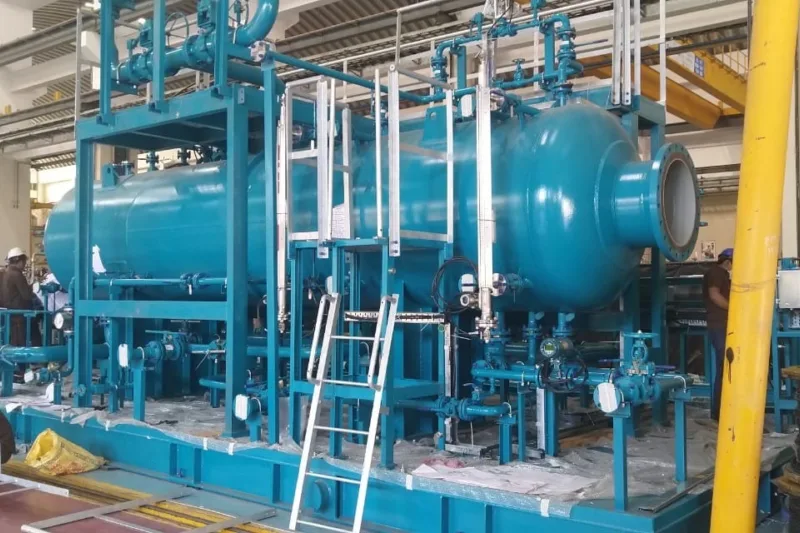

- Production commenced with a single train of standard well test equipment and was subsequently increased with the addition of a second train installed in parallel

- Stabilized crude oil was transferred into the client’s tank farm, from where it was finally exported to an FSO moored offshore

- Although the site was not easily accessible and represented a logistical challenge the in-country team and Expro’s logistics resources ensured a scheduled and safe delivery of the facilities

- The Expro central Production Solutions Product line together with the Expro Nigeria team managed the complete scope from contract award with engineering design, procurement, logistics, installation, commissioning, and start-up

Value to Client

- Installation of the temporary equipment was engineered such that it would not hinder the preparation of foundations and installation of the permanent facility; thereby providing excellent safety performance during SIMOPs

- The piping between the process equipment and production manifold was engineered and designed to minimize the suspension of production when switching from the temporary equipment to the permanent facility; thereby, optimizing uptime, and maximizing production and cash flow for the client

- Expro team provided the O&M services during the initial operation phase of the permanent facility and trained the client’s staff until they took over the operation of the plant

- Zero unplanned shut down, resulting in 100% uptime during operation by Expro team

Contact

For further information, please contact production@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU