Case Study

Instrumenting dual string completions at the sandface

Contact

In Brief

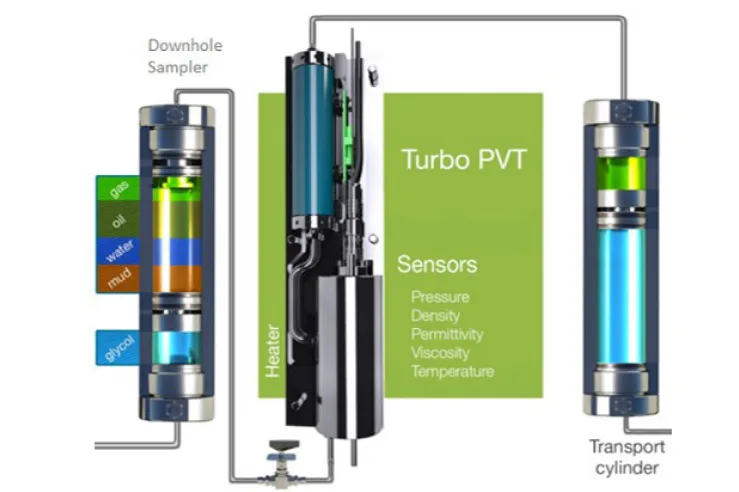

Retrofitting CaTS wireless downhole gauges in a dual string production well in Nigeria enabling measurements at the sandface

Product Line

Customer Challenges

- As part of the Petroleum Drilling and Production regulations in Nigeria, operators are required to report production data to the Department of Petroleum Resources every 6 months. This data must include reservoir parameters including temperatures and pressures

- In the Niger delta region, there are many dual string production wells where Permanent Downhole Cabled Gauges are not being installed. This is mainly due to space constraints in the wellbore and being unable to fit cabled gauge mandrels inside the casing with two production strings present. Furthermore, completion components such as packers would require electrical cable feed-throughs and this has the potential to increase the risk of compromising well integrity downhole

- Other options to capture downhole reservoir data include performing regular surveys with memory gauges/ This increases the number of well intervention operations needed to deploy and retrieve the gauges, which adds time and costs operating the field and impacts on production levels

- Instrumenting dual string production wells with a retrofit wireless gauge and provide data-to-desk is an attractive option for the operator

Expro Excellence

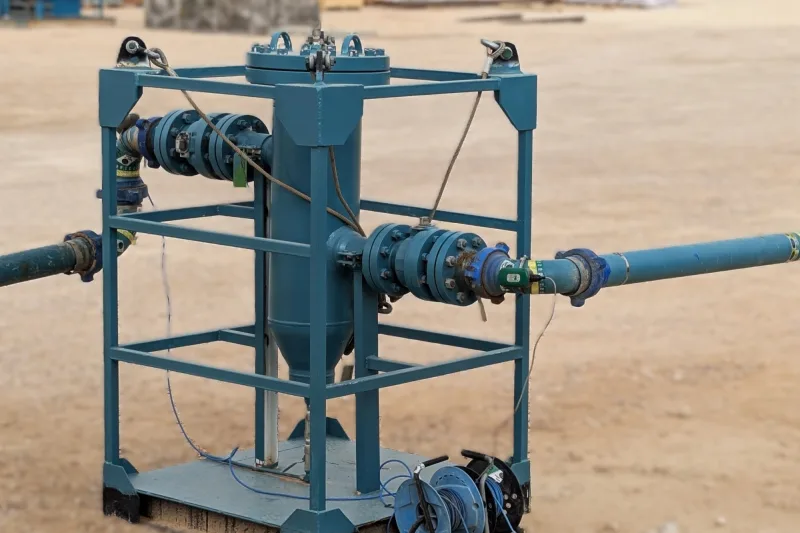

- Our customer provided us with a dual completion candidate well to trial the technology. The well was located onshore near Port Harcourt

- During the planning stage, it was possible for us to influence the completion design and optimise the tailpipe arrangements ready for the CaTS Gauges to be deployed by slickline later. This made the well wireless ready

- Both CaTS Gauges were deployed using standard slickline intervention methods and set into the designated profiles with standard lock mandrels

- The short string gauge was set at just over 8,700ft and the long string was set at just over 9,000ft, in a 54-degree deviation. The wireless signal was transmitted from downhole to surface in a single hop and no repeater tools were required to be set higher in the well

- In terms of data rate, each gauge was set to transmit one pressure and temperature data point every two days with a predicted system life of two and a half years. A slickline intervention would then be required to replace batteries

- The internal gauge memory was programmed to log data every 12mins throughout the duration. Therefore, when the gauges are retrieved a higher density data set can be downloaded and compared with the transmitted SRO data

- The CaTS surface receiver panel was also interfaced to a third party wireless RTU, which relayed data to the local gathering station a few kilometers away

- Both gauges transmitted to a single surface panel and the system commissioned successfully

Value to Client

- The ability to instrument dual completion wells at the sandface without the added complexities of running cabled gauges in this environment can save significiant time and cost when completing the well

- There is less risk of compromising well integrity long-term without running cables through completion components such as packers

- With the wireless gauges installed long-term, there are less interventions required, and this reduces operational risks and minimises impact on production rates

- Ultimately, the operator is able to develop an effective reservoir management strategy and meet their data reporting obligations

Contact

For further information, please contact wireless@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU