Case Study

Customer upgrades clamp-on metering

Contact

In Brief

Customer upgrades clamp-on metering

Product Line

Customer Challenges

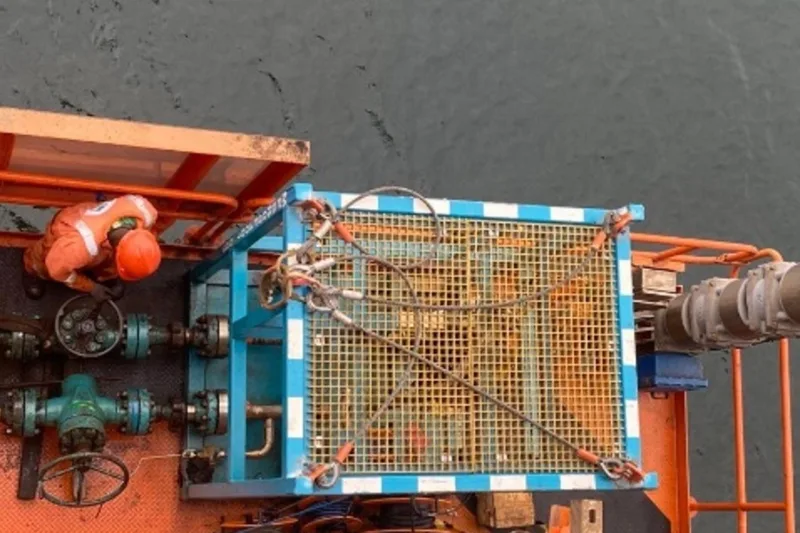

- A major operator approached Expro looking for a metering solution for the produced water overboard line on a North Sea platform

- To meet OSPAR regulations the customer needed to upgrade their existing in-line metering

The customer intitially installed other flow meter types:

- In line mag meter

- Clamp on ultrasonic meter

- Both meters provide unreliable flow measurements due to the high salinity, conductiivity and the presence of oil, fine sand and dissolved gas

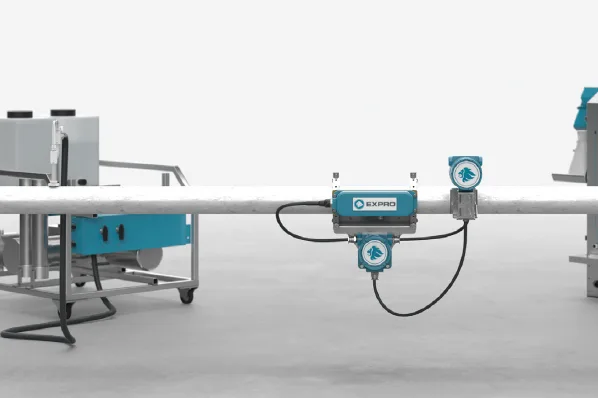

- Expro provided a non-intrusive permanent metering solution which had a measurement accuracy of (± 2%) which was well within the customer's requirements

Expro Excellence

- Our customer was cautious in purchasing a third meter, however an Expro ActiveSONAR™ flow meter was initially provided on a temporary surveillance basis. The meter was clamped onto the pipe downstream of the pipe reducer and also positioned upstream on the in-line magnetic flow meter and on the flow line control valve, non ideal flow conditioning

- There was no adverse effect on the Expro ActiveSONAR™ meter measurement due to the salinity, solids and or oil. Expro's flow studio diagnostics demonstrated the presence of entrained air from the pumps

- Subsequently the flow meter was integrated into the platform DAQ system to provide real time data

Value to Client

- Expro's ActiveSONAR™ meter provided a successful solution in providing metering where multiple flow meter types had failed previously

- The customer was satisfied with the data provided onsite during the surveillance and decided to purchase the meter

- The customer met OSPAR regulations with a measurement accuracy ± 2%

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU