Case Study

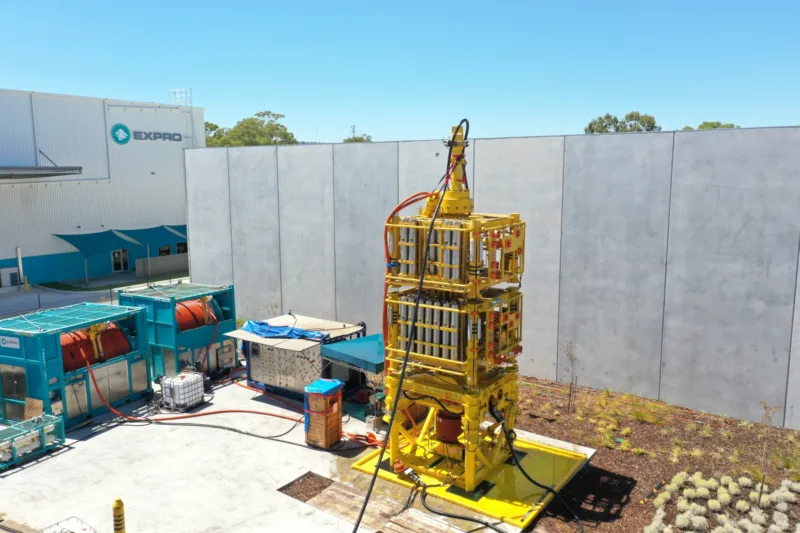

Bespoke subsea system for BP’s Quad 204 development

Contact

In Brief

Bespoke subsea system for BP's Quad 204 development, increasing features despite decreasing size

Product Line

Customer Challenges

- To deliver a suitable landing string for BP's Quad 204 development in the North Sea

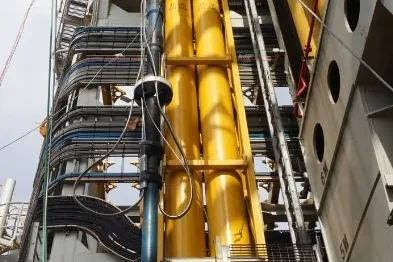

- This was a technically challenging scope of work due to the rig BOP configuration/orientation as well unique completion/installation methods and bespoke SPS interface- this was to suit BP's rig of convenience which was a new semi-submersible was being used that had been optimised for drilling operations and harsh environments

- A dual bore vertical xmas tree (VXT) solution was selected by BP

Expro Excellence

- Expro's long -standing relationship and track record using similar technology, allowed the Subsea team to use previous experience and lessons learnt to ensure complete compliance with the customer's expectations for the project

- Engineering work was undertaken to provide a landing string that fitted the BOP without compromising our customer's specific project requirements, nor reducing the landing string functionality

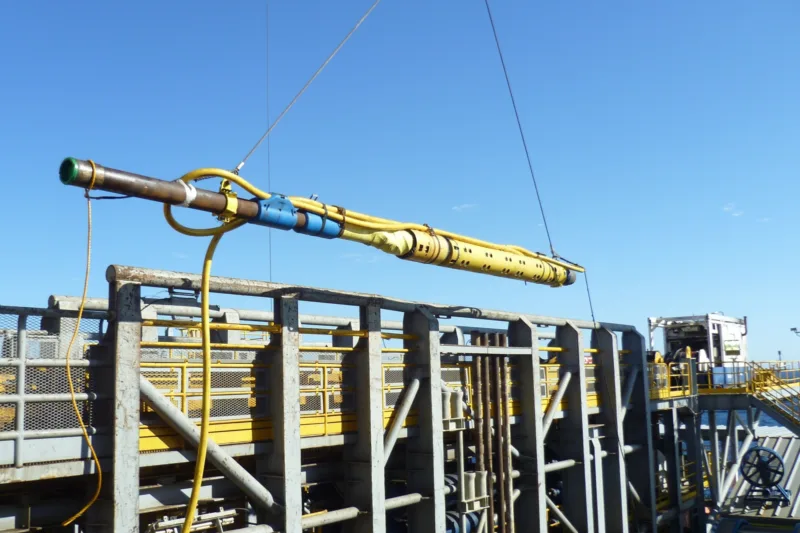

- Re-engineering work resulted in the creation of a combined Integral Slick Joint (ISJ) and Tubing Hanger Running Tool Adapter (THRTA), reducing the overall landing string assembly length so to accommodate the rig BOP dimensions and configuration

- Production and annulus access requirements, along with full helix orientation, BOP and SPS interface challenges highlighted the unique features within Expro's bespoke landing string

- Engineering analysis for FMECAs, stress analysis and multiple GRAs to account for various scenarios were undertaken

Value to Client

- Expro's modular/flexible subsea system allowed use of a rig of convenience

Cost efficiencies due to a reduction in equipment complexity:

- Monobore landing String

- Integral Slick Joint

- No requirement for dual bore riser due to Expro's technical solution, single completion string deployment, full well control inclusive with THOJ/orientation helix arrangement

- Accelerated timeline achieved within nine months, in line with rig delivery

- Expro added value with a dual bore VXT configuration that allowed:

- Orientation helix of BOP alignment included in the system (full well control and disconnect features were not compromised)

- Deployment with monobore tubing, eliminating the need for a dual bore riser

- Primary barriers allowing well flow clean-ups prior to the installation of the dual bore xmas tree

- Provision of dual bore access for manuipulation of the annulus and mechancial access for intervention

Contact

For further information, please contact subsea.enquiries@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU