Case Study

Expro in fire ice again

Contact

In Brief

Expro delivered a bespoke system which was planned to be in hole for 2 months

Product Line

Region

Customer Challenges

- Client wanted to perform an extended well test (60 days) with an ESP pump in the well. During extended well test operations, there is an increased chance that a subsea test tree disconnect will be required. To minimise potential downtime in these scenarios, ESP cables are required to be disconnected and reconnected at the subsea test tree latch interface

- Expro had successfully completed an operation for the same client in 2017 and they approached us again as a result of our track record and experience in methane hydrate operations

- Expro has both a strong presence in China and a strong reputation in subsea operations

- The customer was looking for an Electro-Hydraulic Deepwater E&A system, which could be modified for use in a methane hydrate testing environment

Expro Excellence

- For many years, Expro is the market leader in providing solutions for well testing operations and we are currently the only provider of systems which enable subsea test tree disconnect and reconnect to be conducted at the seabed and re-establish power to the ESPs deployed downhole

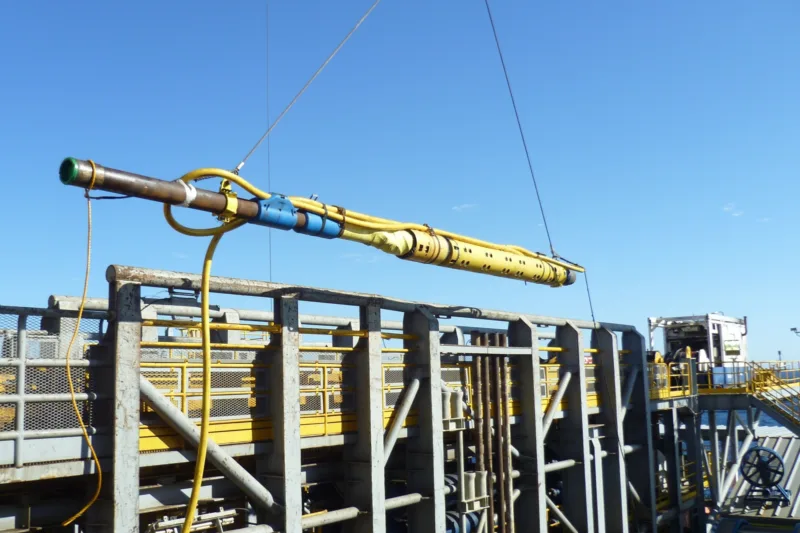

- The latest systems have been developed, with wet-mate connectors for each phase of the power cable enabling standard subsea test trees to be converted and used during well test operations. When deploying a power cable, different secondary disconnect systems are required, as string rotation for mechanical disconnect is not an option. Additional equipment to enable closure of annular rams and activation of the secondary system by pressure application underneath closed rams is included

- One of our main challenges in this project was the accelerated delivery of a more complex subsea string. After the project was awarded the delivery date was brought forward by several months

- If we had not met this tight time frame this would have resulted in a significant disruption of the client’s drilling and testing schedule with potential commercial impact due to rig standby

- Expro had to utilise and modify existing project specific assets rather than build bespoke equipment to ensure delivery

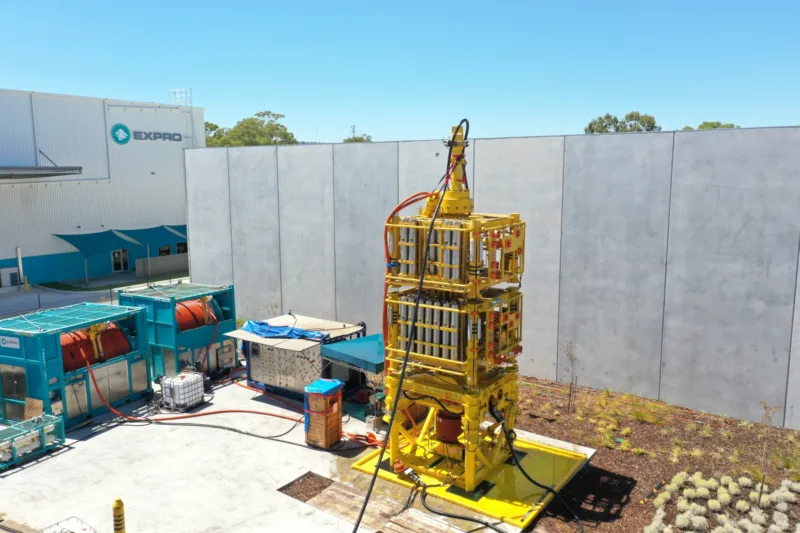

- Our Electro-Hydraulic deep-water subsea system was modified to suit and provide the electrical conduits to the downhole ESP and monitoring package

Value to Client

- Expro delivered a bespoke system which was planned to be in hole for two months

- The subsea system was reliable and the performance was vital in the completion of the extended well test

- Our equipment performed flawlessly throughout the project and allowed the extended well test to completed without issue or compromise

- Expro is the only provider of subsea system with wet-mate connectors for downhole ESP power cables. These systems have been used on projects evaluating well for methane hydrate, heavy oil and carbon capture where downhole ESPs were used

Contact

For further information, please contact subsea.enquiries@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU