Case Study

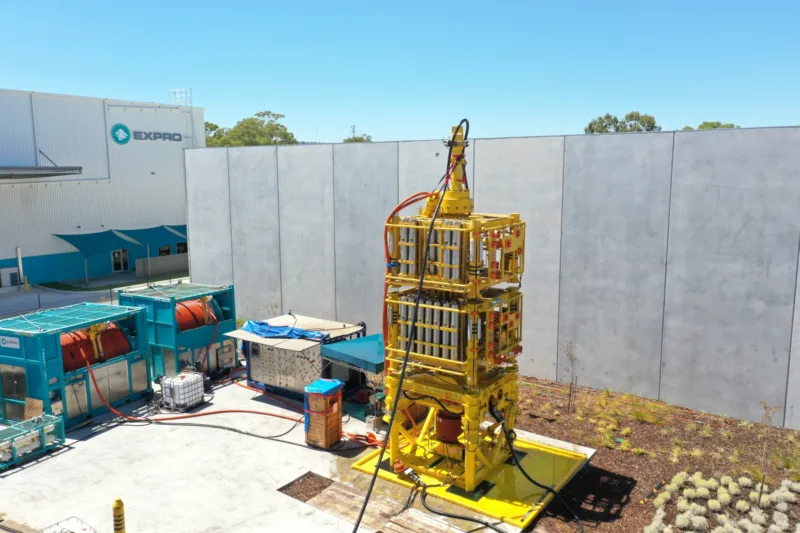

Expro completes nine well decommissioning campaign with zero NPT

Contact

In Brief

Expro's large bore SSTTA reliability contributes to successful abandonment of nine subsea wells in Ireland's first decommissioning project

Product Line

Customer Challenges

- This was the first decommissioning project in Ireland with the campaign requiring the abandonment of nine subsea wells, utilizing an anchored semi-submersible offshore drilling unit

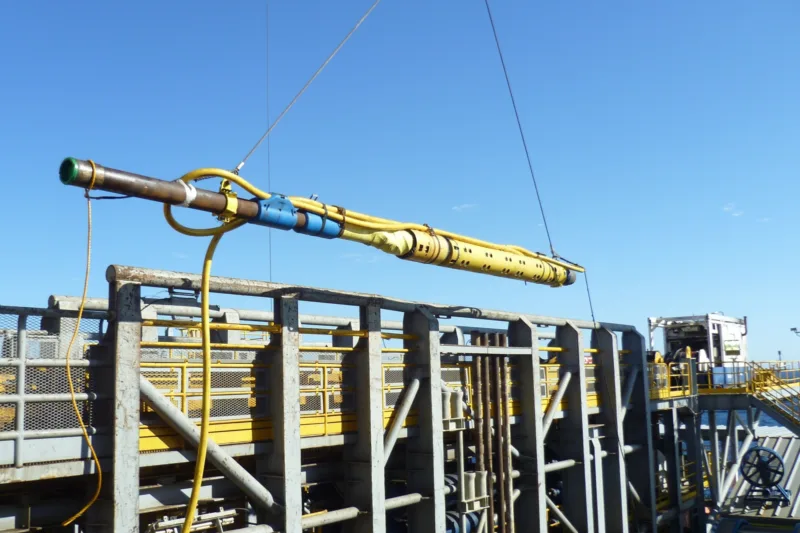

- The customer had a requirement for a throughBOP intervention riser system, complete with topside direct-hydraulic control system, to provide well barrier isolation and disconnect capability during a subsea well abandonment campaign in the challenging environment of the Celtic sea

Expro Excellence

- Expro provided both a primary and back up 7-3/8” ELSA-DH SSTTA c/w offshore service personnel as well as project management, interface engineering services personnel to deliver the customer’s scope of work

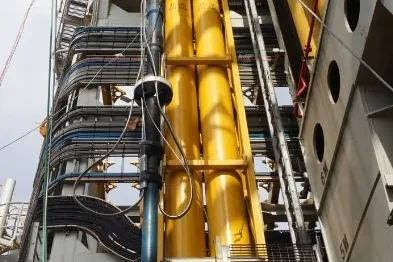

- The primary and secondary 7-3/8” ELSA-DH SSTTA systems performed three operations each, with maintenance performed on the primary system to complete the final wells

- Maintenance was carried out on the primary system whilst the secondary system was utilized allowing the rig time to be optimized between operations

- The system was unlatched at the subsea test tree for over 93 hours due to the weather conditions and relatched with no issues, proving system reliability

- Safety was the key priority in delivering fit for purpose equipment and carrying out the customer’s work scope

Value to Client

- The nine well campaign was executed successfully, with over 1,290 in hole hours with zero NPT, during COVID-19 pandemic

- The client commended Expro’s performance when evaluating our service quality, equipment performance, QHSE, communication, and proactive personnel

- The equipment was delivered on schedule with a short planning time from Expro’s global subsea support hub in Aberdeen

- Expro provided a cost-effective fit for purpose solution for the customer, based on the well parameters and challenging harsh condition

Contact

For further information, please contact subsea.enquiries@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU