Case Study

DAV MX: Field-proven solution delivering 46-hour rig-time savings in unconventional reservoir

Contact

In Brief

Phenomenal time savings delivered utilizing DAV-MX in Argentina

Product Line

Region

Customer Challenges

- A major operator in Argentina was drilling the 171.5 mm (6 3/4") horizontal section in the unconventional shale reservoirs of the Vaca Muerta Formation, utilizing Managed Pressure Drilling (MPD) and Oil-Based Mud (OBM) with a density of 1,650 kg/m3 (13.7 ppg)

- The operator experienced partial fluid losses. Despite pumping LCM at low concentrations, the losses persisted, and flow-out trends indicated a progressive deterioration of returns until reaching a condition of total losses

- As part of ongoing field trials of the Expro DAV MX Circulation Sub, and upon recognizing its potential to address the severe losses, the client approved its deployment in this well. This deployment represents the second instance in which the maximum LCM concentration equivalent to 400 kg/m3 (~140 ib/bbl), as defined by the operator's decision tree for total fluid loss mitigation, was pumped through the valve

Expro Excellence

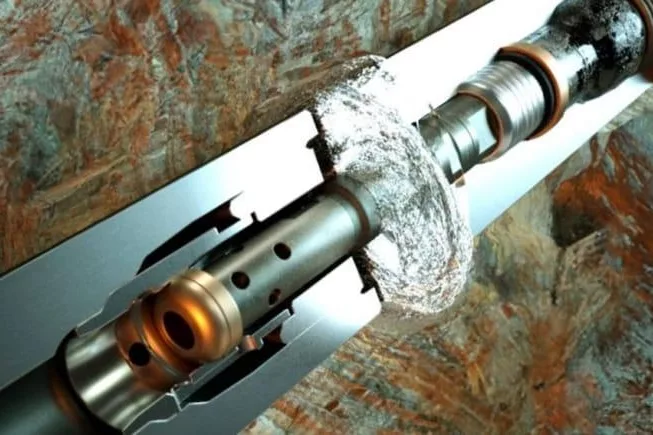

- Expro's 127 mm (5") OD DAV MX, equipped with two 19.1 mm (3/4") side ports, was placed in the closed position above the directional drilling tools within the BHA, allowing it to remain dormant during normal operations. The DAV MX provides the capability to open and close the flow path to the annulus up to five times. Upon dart activation, the tool is capable of diverting flow, providing an effective bypass around sensitive downhole components

- Each cycle involved a reliable open/close sequence, with clear surface indications confirming the opening dart landing and ports opening. After sequentially pumping 22m3 sweeps by two activations with 12 m3 sweeps of 400 kg/m3 (140 ppb) LCM concentration, ports closure were confirmed by a pressure increase when the Universal Closing Dart (UCD) sheared the opening dart into the catcher, validating proper tool function

Value to Client

- The DAV MX was successfully activated on three occasions using the 50.8 mm (2") OD Ultra-Series Standard Diverter Dart (SSD). All darts were circulated to the valve within a string volume, and deployment velocity clearly demonstrates the rapid and efficient performance of the darts, ensuring timely activation during critical operations

- For the client, who had previously used in another well in the area the Ultra-Series Split Flow Dart (SFD) - which distributes flow between the BHA and the ports - this run served as a clear demonstration of the tool's versatility

- The successful open/close cycles, efficient LCM treatment, and consistent surface indications confirmed the tool's performance under challenging operational conditions, validating the DAV MX as a reliable and robust solution for managing severe losses in unconventional reservoirs

- The operator saved 46 hours by deploying the DAV MX to pump high-concentration LCM, thereby eliminating conventional remedial operations. These operations typically required pulling the drilling BHA to surface, running an open-ended string, spotting LCM, retrieving the string, and subsequently re-running the directional BHA to resume drilling

- With losses under control, the well successfully reached the planned Total Depth (TD) of 7,080 meters (23,228 ft)

Contact

For further information, please contact coretrax@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU