Case Study

HI Tool replaces competitor in 8 1/2" build section, reduces Stick-Slip by 76% and boosts ROP by 18%

In Brief

A reputable customer in the Middle East drilled an 8 1/2” build section using a competitor's vibration mitigation tool.

Product Line

Region

Customer Challenges

- A reputable customer in the Middle East drilled an 8 1/2” build section using a competitor’s vibration mitigation tool

- Severe stick-slip and high-level lateral/axial shocks were observed throughout the section, significantly impacting drilling efficiency and equipment stress

- These dysfunctions not only compromise bit life and BHA integrity but also reduce drilling efficiency and increase operational costs

- In the sidetrack section, the client aimed to drill the same 8 1/2” build section using Expro’s HI Tool as an alternative solution

- All conditions remained consistent: same rig, same formation, same bit and BHA specs, and identical mud properties — the only variable changed was replacing the competitor tool with the HI Tool

- Expro was chosen for the sidetrack due to our strong field record, engineering support, and proven performance in vibration-sensitive environments

Expro Excellence

- Expro deployed the HI Tool in an 8 1/2” sidetracked build section on top of RSS BHA after poor performance was observed with a competitor tool in the original hole

- All conditions were identical between the two runs (rig, formation, bit, BHA, mud); the only change was replacing the competitor tool with the HI Tool

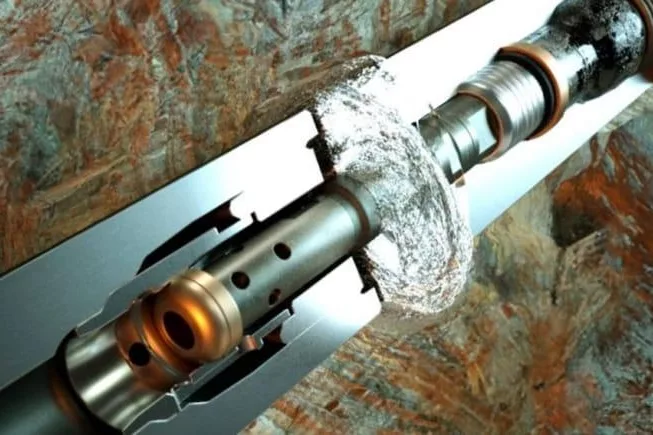

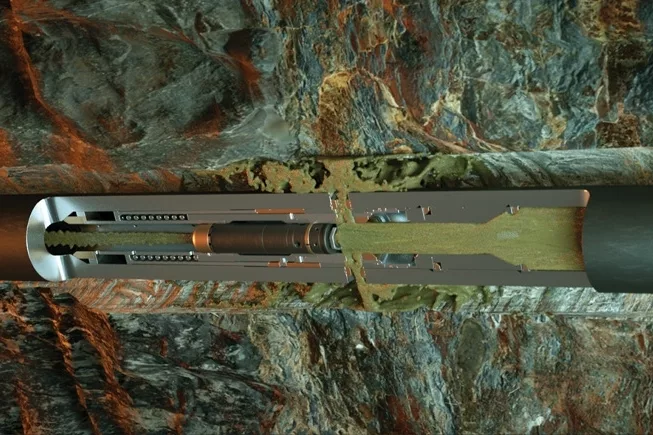

- The HI tool is designed through its gear connection to decouple the BHA and drill bit from drill string dynamics and redistribute the high shock loads in the drill string to the wellbore

- By isolating the drilling dynamics from the bit, the bit will be able to drill uninterrupted with full

contact with formation and better cutting structure and improved bit efficiency , which results in more efficient energy for rock cutting and less stick slip vibrations

Value to Client

- The 8,612 ft build section was drilled in 1 BHA run (shoe to shoe)

- Stick-Slip Reduction:

- Stick-slip index (SSI) dropped from 332.4 c/m (competitor) to 79.5 c/m (HI Tool) — a 76% reduction

- 75% of the section drilled with the HI Tool had low-to-medium stick-slip

- In contrast, the offset section with competitor tool saw high-to-severe stick-slip in 97% of the section

- Vibration Management:

- HI Tool significantly reduced the frequency of high-level lateral and axial vibration peaks

- Drilling Performance:

- Enabled wider drilling parameter envelope (higher RPM and WOB) while maintaining vibration control

- Improved mechanical specific energy (MSE) due to reduced stick-slip and shock

- Achieved 18% increase in ROP compared to the competitor tool

- One-run success with HI Tool eliminated additional trips and reduced overall drilling time

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU