Case Study

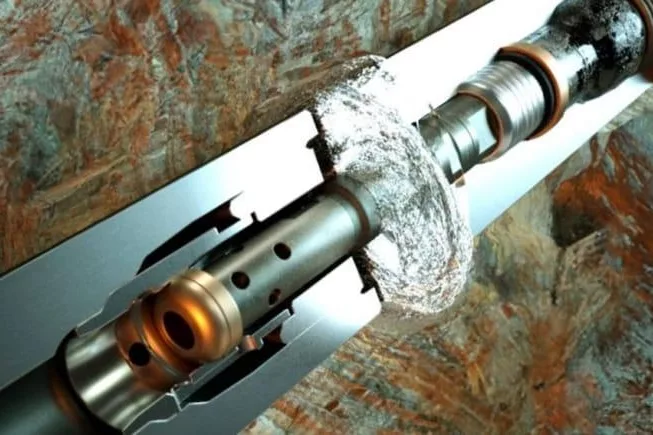

Pioneering the world’s first 7 5/8” Reg HyPR Holesaver™ cut

Contact

In Brief

Achieving a world-first 7 5/8" Reg HyPR Holesaver™ cut, setting a new benchmark in well construction

Region

Customer Challenges

- During drilling a highly deviated gas well, total losses were encountered in the 17.5” section

- The customer attempted to mitigate losses by pumping LCM and eventually performing a cement squeeze job

- The losses recurred twice while drilling with two separate BHAs. On the third BHA, following the cement job, the string became stuck at 7,422ft at an inclination of 63 degrees

- Jarring operations proceeded to pump acid, however, this approach was also unsuccessful

- The decision was taken to sever the string using the HyPR Holesaver™ tool which enabled the customer to: • Recover the drill string above the HyPR tool

- Attempt fishing operations on the fish profile left on the HyPR tool to recover the remaining stuck BHA below the HyPR tool

Expro Excellence

- Expro operates under a five-year contract with the customer

- The HyPR HoleSaver™ and DAV MX™ tools were preplaced into the drillstring during the job design with Expro guidance to offer a complete contingency option where they can be activated as and when drilling challenges arise, such as mud losses or stuck pipe events that occurred in this well

- HyPR HoleSaver™ was subsequently activated by the rig crew with the guidance of the Expro onshore support

- Pipe severance was immediately achieved once the decision to sever the pipe was made - no additional equipment or personnel required for the operation

- A fishing dart was deployed allowing the operator to fish for the remaining BHA. After deploying the dart, the flow rate was increased, and the cut commenced

- The HyPR HoleSaver™ profile allowed for fishing operations to commence immediately and for the safe efficient recovery of the remaining BHA

- This was the first 7 5/8” HyPR Holesaver™ pipe cut for this pipe size in Expro history

Value to Client

- Upwards of 72 hours were saved against a traditional stuck pipe recovery operation, completed in just 12.5 hours

- Significant cost savings were achieved by successfully recovering all drill pipe equipment and drill pipe above the HyPR Holesaver™ tool

- Unlike traditional methods, the HyPR Holesaver™ tool does not require the use of wireline cutting tools or explosives eliminating the need to deploy specialist wireline crews and reducing third party operational and mobilization costs for the customer

- The HyPR Holesaver™ tool allows for multiple options where either fishing or cementing operations can resume immediately

- The DAV MX™ and HyPR Holesaver™ are designed to be ran by the client with onshore Expro support reducing POB

Contact

For further information, please contact Coretrax@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU