Case Study

Coretrax MAXVAX & DAV MX Combined for Successful Recovery of ESP Bands Lost Downhole for ME Operator

Region

Background

After pulling an ESP completion to surface, it was identified that 5 metal bonds were missing from the packer and needed to be recovered to allow for the well to be clean and debris free for recompletion.

A conventional reverse circulating junk sub was deployed to 7,135ft and 63° inclination and reverse circulating was initiated. Upon the tools returning to surface, no bands had been recovered and a second run was sanctioned. After a second run one band was recovered, but it was recognized that a different approach was required to quick remove the remaining ESP metal bands.

Solution and Operation

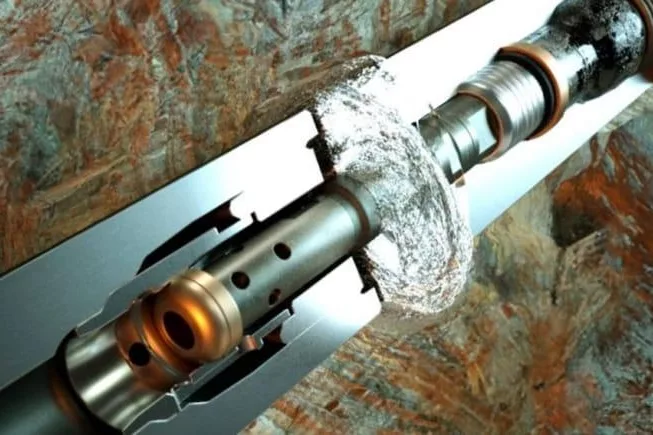

The Coretrax MaxVax was deployed with a DAV MX circulating sub to create optimum well conditions for debris recovery.

Function tested at surface, the tools were ran to 7,135ft and a 30bbl hi vis pill circulated. On the first run, 2 bands were recovered with a second run recovering the remaining 2 bands leaving the well clean and ready for the next stage of operations.

Achievements

- All bands recovered efficiently, fishing the components quicker than conventional methods

- MaxVax and DAV MX were run together to create the conditions required with the 8.6ppg (65pcf) brine without any requirement to displace incumbent well fluid

- Tools created a powerful fluid vacuum allowing for debris to be captured from the low side quickly and easily, overcoming challenging well deviation (63°)

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU