Case Study

Expandable clad solution enables full-bore access while reducing oil-based mud losses

Contact

In Brief

Enabling full-bore access and lowering oil-based mud losses with a reliable expandable clad system

Product Line

Region

Customer Challenges

- The client had an open hole interval from 11,150’ to approximately 12,850’, which was known to encounter significant losses while drilling the horizontal section

- The losses resulted in substantial non-productive time (NPT) during hole conditioning and led to large financial losses due to consumption of oil-based mud

- The conventional solution of installing an additional liner (7 5/8’ x 9 5/8’) would have reduced the production hole size to 6.750’, increasing costs due to the need for premium 5.5’ production casing and potentially compromising cement quality due to the tight annular clearance

Expro Excellence

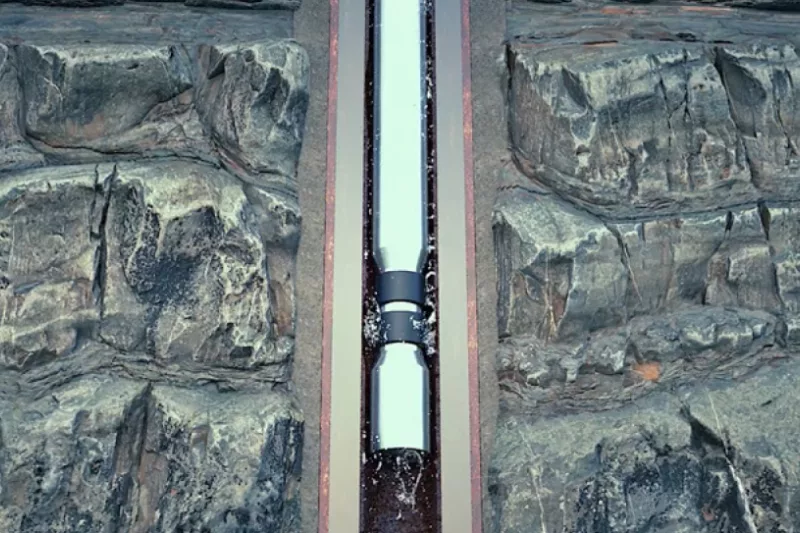

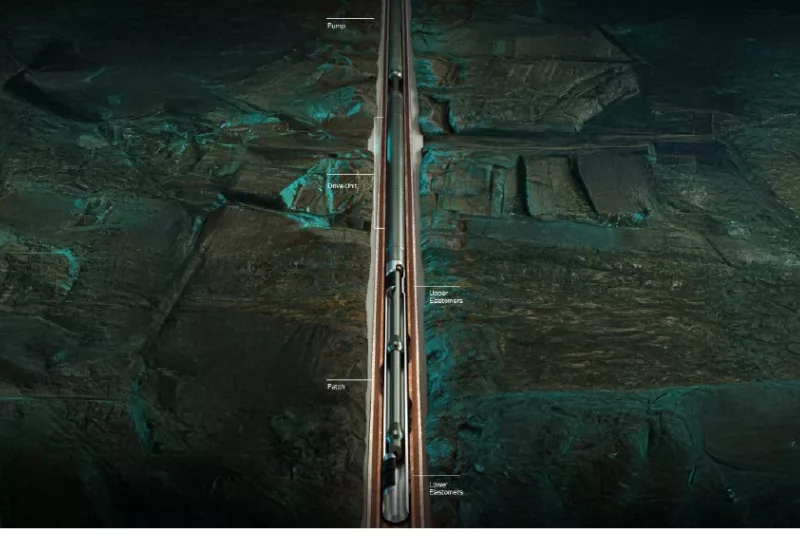

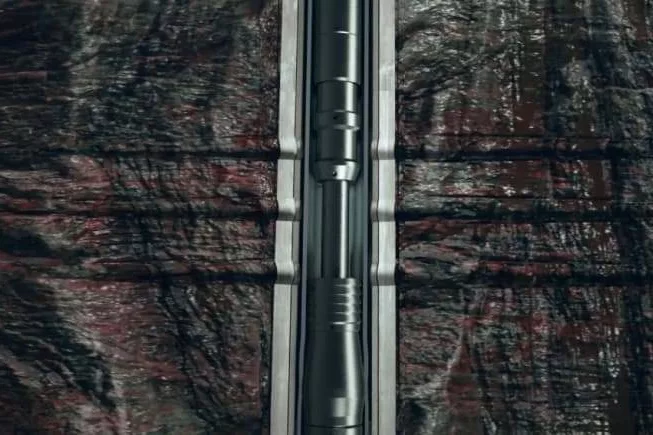

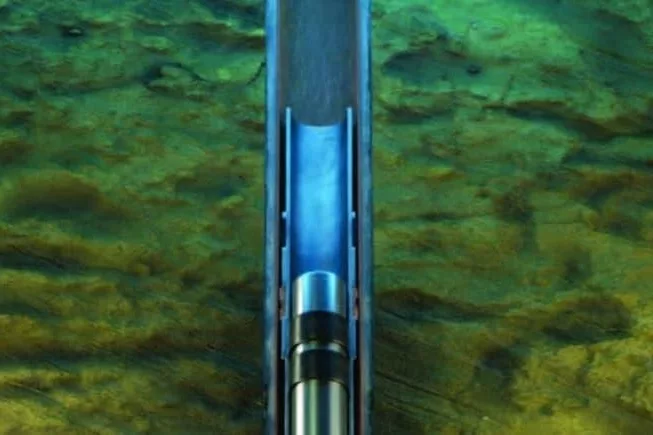

- Expro deployed a 2,000’ ReLine DL OH expandable system. The liner was anchored in the 8 ¾” open hole with cement expanded and tied back into the 9 5/8” 40lb intermediate casing. The system has a post-expanded ID of 7.997’ allowing the client to run 7 7/8” drilling tools through the interval to total depth (TD)

- This solution prevented further fluid losses and enabled installation of the next 7 5/8” liner per the well construction plan

Value to Client

- The liner was successfully installed, covering the interval from 11,038” to 12,935” maximizing internal diameter and mitigating major oil-based mud losses

- The operator had planned these wells months in advance to ensure all necessary equipment was available on location

- Additional value was delivered to the client through Expro’s ability to provide a combined service offering. By utilizing Expro’s TRS and Blackhawk Top Drive Cement Head alongside the CORE Reline DL system, Expro delivered a one-stop solution for the client

- A key driver to success of this project was the ability to store and mobilize equipment from our Midland facility reducing call out time and logistical costs

Contact

For further information, please contact coretrax@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU