Case Study

Expro delivers Tubular Running Services for Hirai CCS project

Contact

In Brief

Expro runs high-chrome tubulars for INPEX CCS project in Japan

Region

Customer Challenges

- INPEX engaged with Expro to support the Tubular Running Services for the Hirai CCUS project involving the completion of three wells

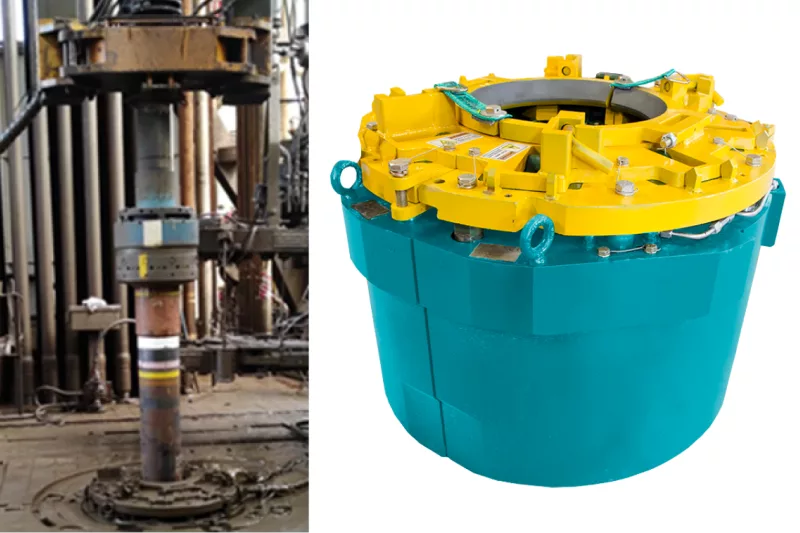

- Our customer faced technical challenges which required expertise in the installation of corrosion-resistant alloy (CRA) tubulars, including 13Cr Super Chrome pipe

- The CRA chosen by INPEX has strict handling procedures to preserve the finish and needs highly reliable tubular running operations to protect the pipe whilst handling and running

- It is essential that tubulars are not damaged while running the completion, to mitigate the risk of corrosion and integrity issues in the future

- INPEX is a long-standing client, and chose Expro due to our proven track record in safe, efficient CRA handling, access to specialized equipment and our high-performing, experienced team

Expro Excellence

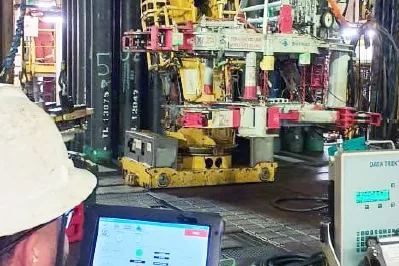

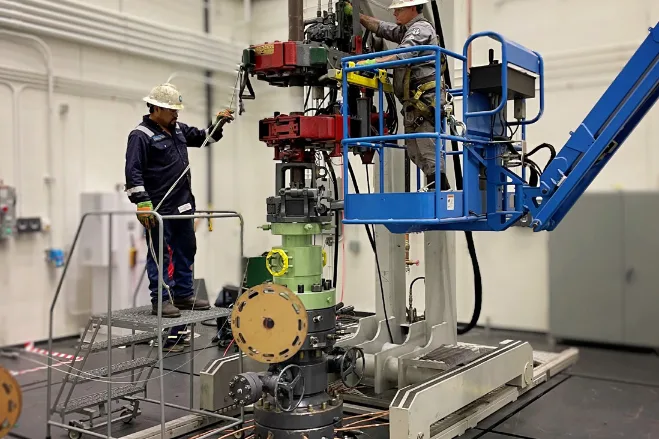

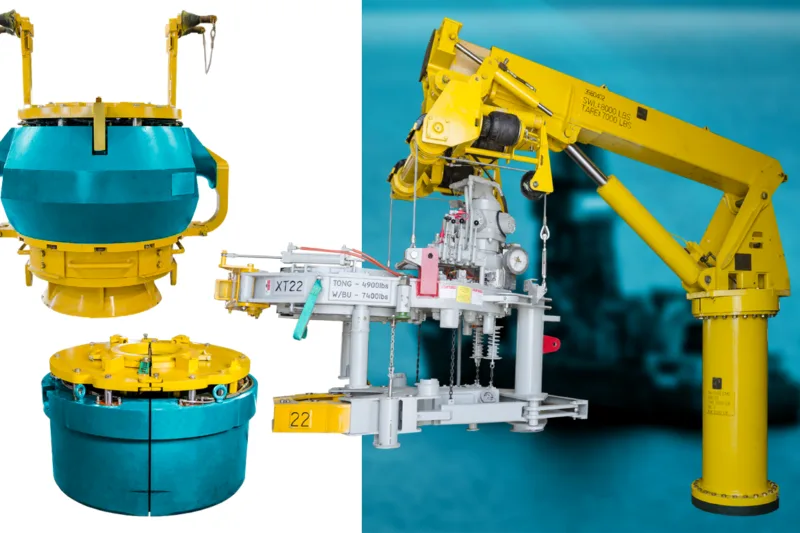

- Expro was responsible for providing tubular running services for six casing and tubing sizes: 20”, 13-3/8”, 7”. 3-1/2”, and 2-3/8” as part of the Hirai project

- The scope included the conventional running of casing using power tongs, along with specialized handling and make-up for the CRA tubulars 13 Cr Super Chrome from 7” to 2-3/8” (COBRA CLMA, RS350/250 spiders, and Fine Point dies)

- The operation involved the integration of a 1” flat pack control line, which required precision and co-ordination during the run

- Expro’s key differentiator was in the deployment of our dedicated CRA handling equipment and our welltrained crew, all specifically selected to protect the integrity of the CRA connections and pipe body

- Our strong working relationship with INPEX was supported by our local agent KBK, who played a key communication role, ensuring alignment throughout the project and reinforcing Expro’s service quality

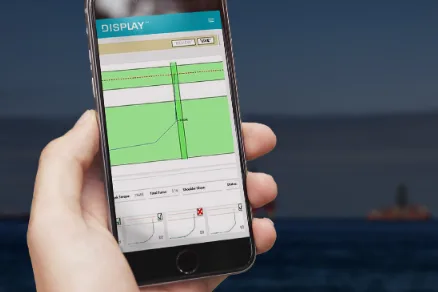

- Proper planning, pre-job equipment checks allowed for a seamless execution

- Expro delivered a tailored solution, providing the right equipment and skilled personnel to ensure success while strengthening the client’s trust in our ability to perform under technically demanding conditions. Our unwavering commitment to quality, safety, and technology-driven innovation positioned us as the preferred service provider

Value to Client

- The successful execution of the Hirai CCUS tubular running campaign delivered significant value to INPEX with zero NPT and no equipment related issues

- All tubulars (including CRA strings and the control line) were run smoothly in a single attempt, resulting in cost savings and operational efficiencies

- Expro’s technical expertise, reliable equipment, and skilled crew ensured the integrity of high-value CRA tubulars was preserved helping the client avoid potential damage-related costs, delays and future well integrity or recompletion work scopes

- 95% Job Performance Report, illustrating INPEX’s high level of satisfaction

Contact

For further information, please contact ExproSES@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU