Case Study

Expro drilled and set 13-3/8” Casing, 17 hours ahead of schedule and saves 17 hours delivering CwD services with FA-1

Contact

In Brief

Expro saves operator 17 hours with its CwD expertise

Product Line

Region

Customer Challenges

- The customer was looking to reduce drilling time and enhance the efficiency of the well construction in a shallow-water exploration well

Expro Excellence

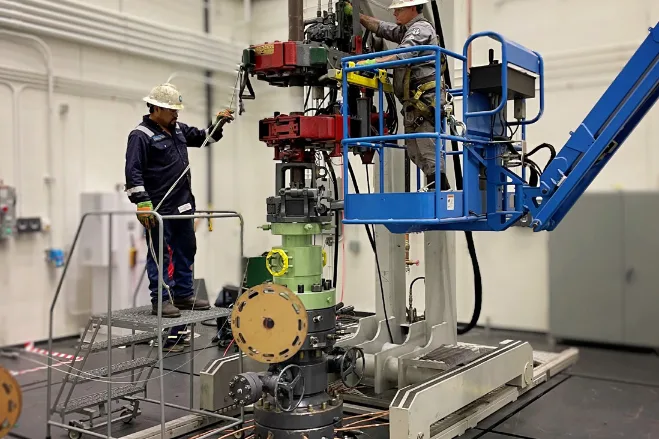

- Expro provided hydraulic and torque and drag engineering analysis

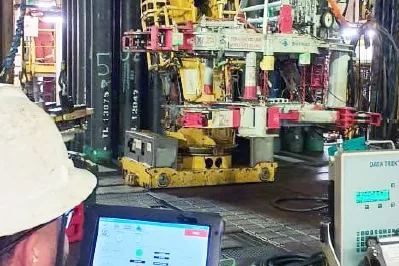

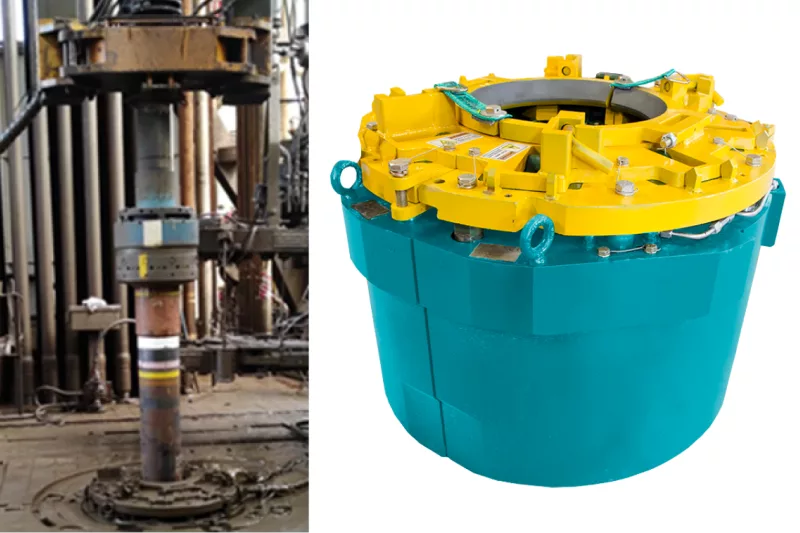

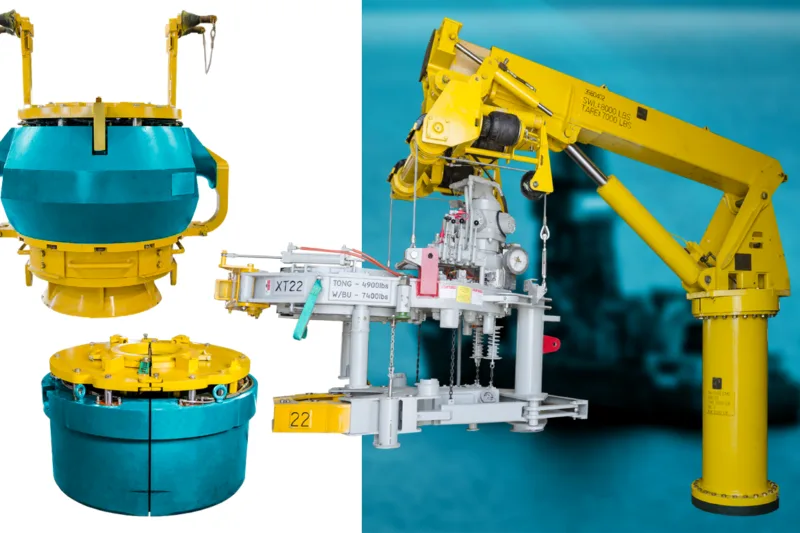

- Expro was able to perform the drilling operations with a robust hydraulic casing running tool (CRT) FA-1 – 14”

- Expro provided CwD service to drill and case the hole, simultaneously

Value to Client

- We reached TD 17 hours ahead of the customer schedule without any NPT and managed to save costs for the customer

- Drilling through hard stingers and managed to case and cement the hole section in a single trip, without mobilizing a full drilling BHA and its related consumable component

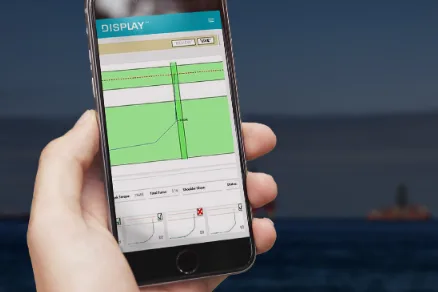

- Utilization of Expro’s Tubular Running Services’ FA-1 Hydraulic CRT enabled a seamless drilling process from remote pick up of casing from the V-Door, connector make-up and torque monitoring, fill-up, reciprocation and drilling

- The FA-1’s intelligent interlock system, providing safety interlock and remote driller visibility of status of the spider, the CRT, single joint manipulator, and single-joint elevator reduced manual handling and kept personnel away from the red zone, while enhancing communication between the drilling and casing crews

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU