Case Study

Norway’s first deployment of the Blackhawk Cement Head cuts HSE risk and saves rig time

Contact

In Brief

Norway’s first deployment of the Blackhawk Cement Head reduced HSE risk and delivered significant rig‑time savings

Product Line

Customer Challenges

- A major North Sea operator had relied on manual cement heads for full-bore casing cement jobs for many years. However, the use of conventional manual cement heads created significant HSE exposure due to repeated entries into the red zone, including man-riding and working at height during rig-up, rig-down, and operation. These manual activities not only increased risk to personnel but also constrained overall operational efficiency

- Aligned with their HSE improvement objectives, the operator sought a fully remote-operated full-bore cement head that could eliminate hands-on intervention, reduce exposure to high-risk areas, and maintain-or improve-operational performance

Expro Excellence

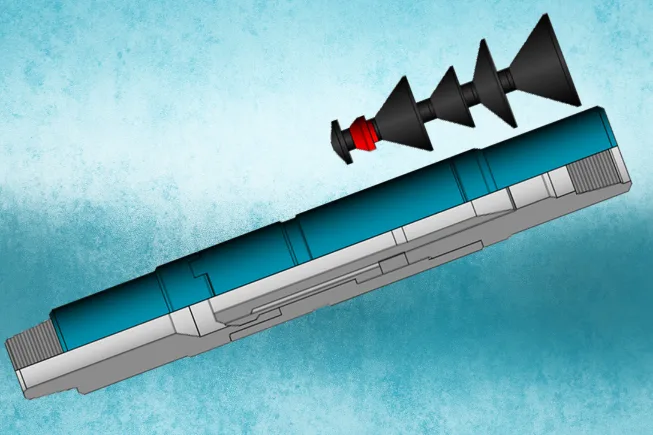

- Expro proposed deploying the Blackhawk wireless, remote-operated rotating plug launcher cement head integrated with the Skyhook system – to trial the technology and demonstrate its operational and HSE benefits

- The wireless technology enables all cement head functions to be performed from a safe location outside the red zone, removing the need for manual intervention

- The Skyhook system further enhances safety and efficiency by providing a completely hands-free method of connecting high-pressure hoses or iron to the cement head – an industry step-change compared with conventional equipment. The cement line can be connected without personnel entering the red zone, this task can be completed offline while pre-job circulation is underway, delivering measurable time savings

- Additional efficiency gains are achieved by configuring the cement head with the correct casing connection prior to operations. This allows the TRS equipment used during casing running to also support rig-up and rig-down activities, while enabling the casing running tool to deliver higher pre-job circulation and post-job displacement rates

Value to Client

- Across three completed jobs, the operator experienced zero HSE incidents and zero NPT, demonstrating the reliability and safety of Expro’s solution. The Blackhawk wireless cement head, combined with the Skyhook system, eliminated all red-zone entries – previously as many as twelve per operation – significantly reducing personnel exposure

- The operator also realized meaningful time saving, with 2-3 hours reduced from rig-up and rig-down compared with earlier manual equipment

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU