Case Study

SeaCure Zero Shoetrack Solution - Cementing Tech

Contact

In Brief

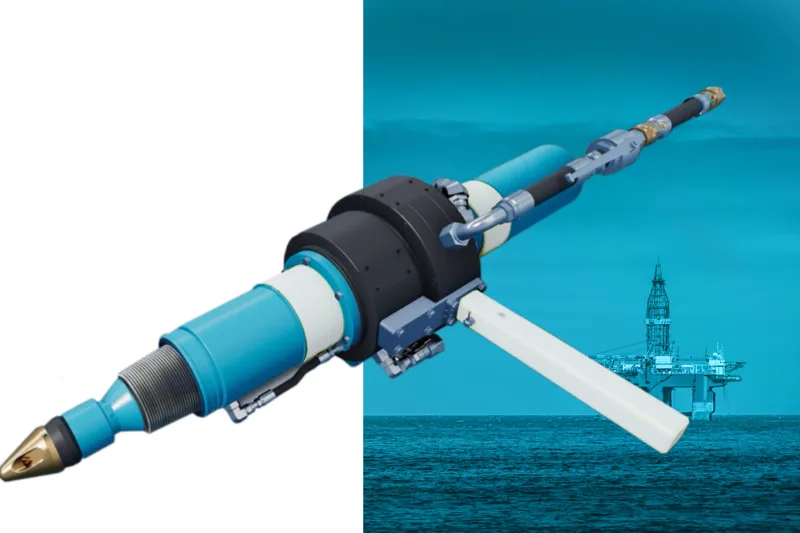

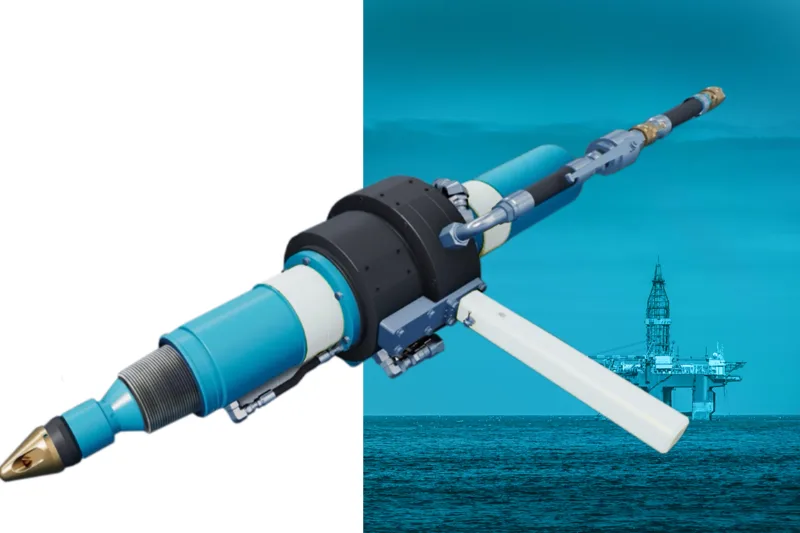

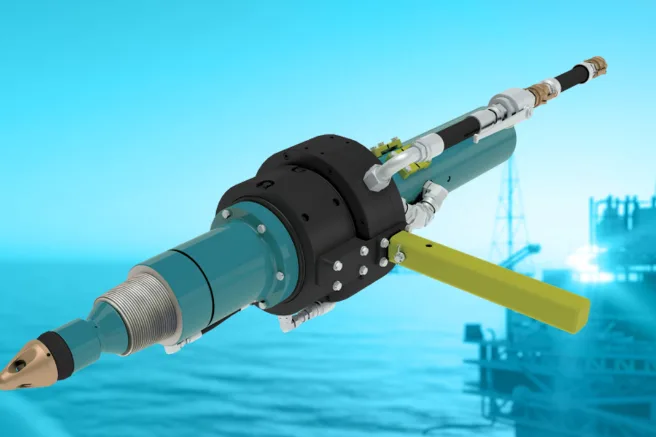

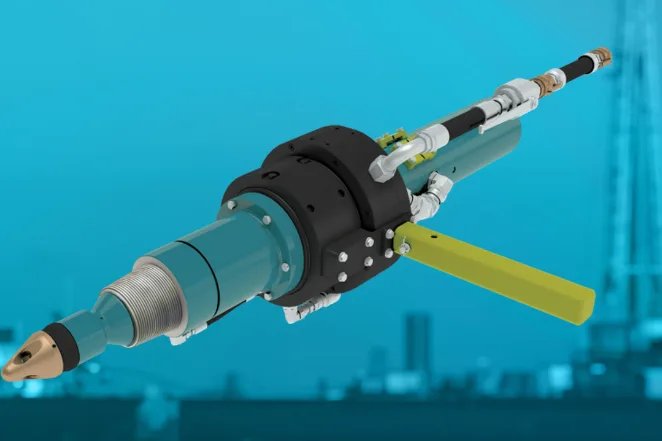

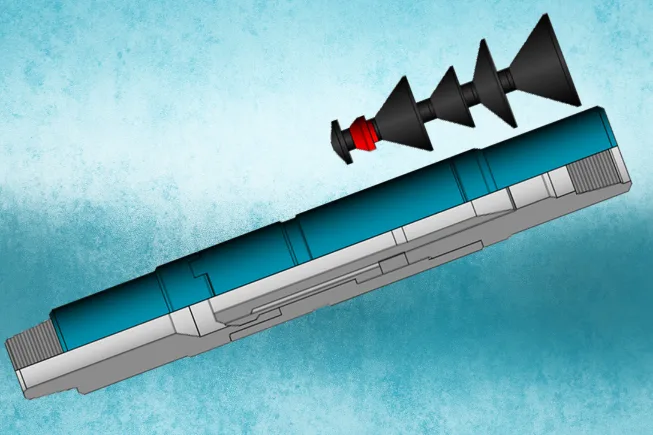

SeaCure® zero shoetrack solution enables reliable pilot hole drill ahead

Product Line

Customer Challenges

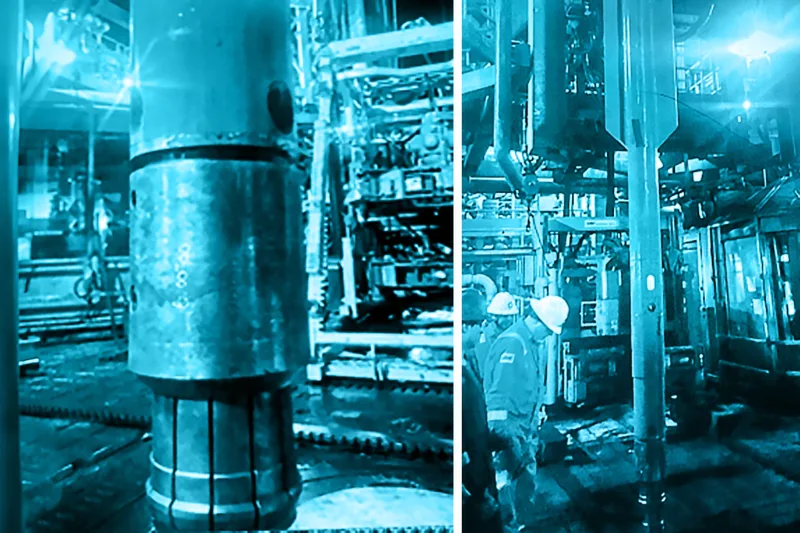

- The customer had the requirement for an 8 ½” pilot hole drill ahead out of 13-3/8” shoe which had previously needed a clean out trip to clean out the shoetrack or significant risk of a stuck Bottom Hole Assembly (BHA)

- The operator was seeking a solution to an NPT event from their previous campaign

Expro Excellence

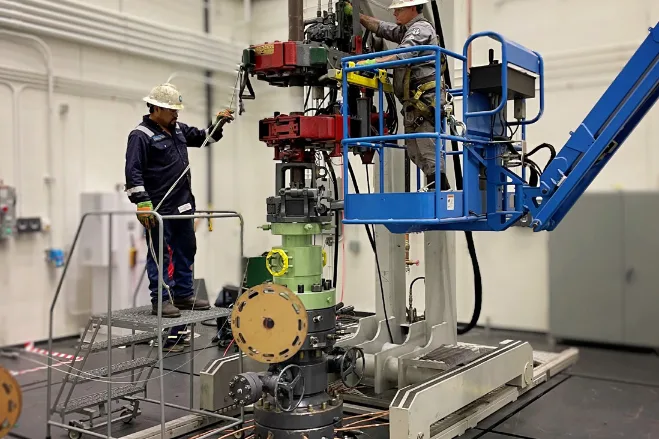

- Expro’s SeaCure® delivers a zero shoetrack solution, enabling 81/2” drill ahead out of 13 3/8” shoe and removed the requirement for a clean out trip/risk of a stuck 8 ½” Bottom Hole Assembly (BHA)

- Our simple, reliable SeaCure® operation eliminates all risks from previous NPT event to deliver a zero NPT solution

Value to Client

- Our solution saved the customer multiple hours and MT of CO2 on critical path operation in comparison to a previous campaign

- The drill out of 13 3/8” shoe with 8 ½” pilot hole Bottom Hole Assembly (BHA) in 30 mins

- The surface casing cement job displacement volume reduced to 46bbls (7m3)

- Our SeaCure® latch in adaptor moving the hydraulic seal to conduct the cement job to the shoe and removing the risks associated with running tool/ball valve leak

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU