Case Study

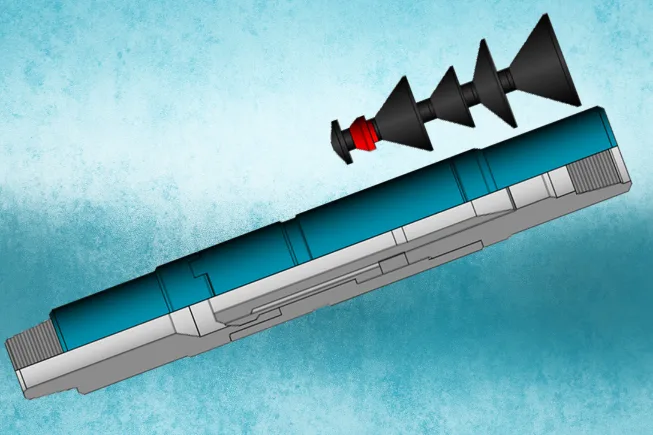

Gen-X Quintuple wireless cement head with SkyHook™ 9-5/8" two stage cement job

In Brief

World's first hands free five plug stage cementing operation with Expro's Gen-x Cement Head and SkyHook™

Product Line

Region

Customer Challenges

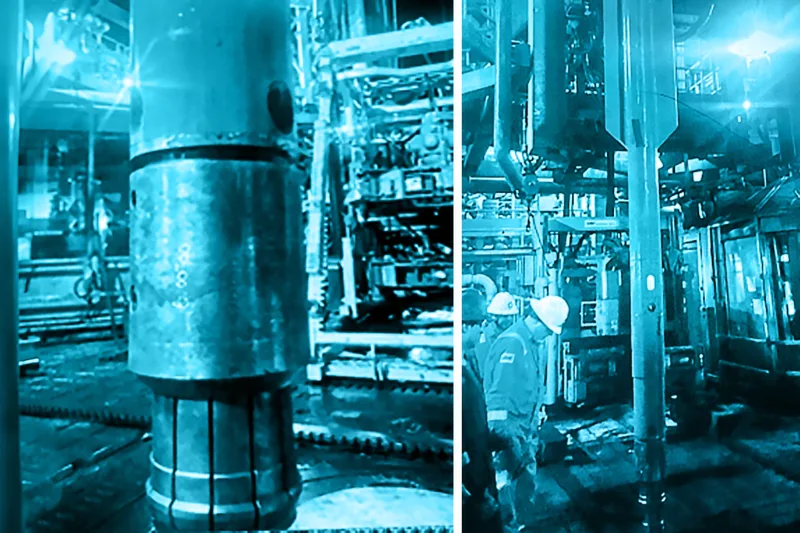

- Expro’s cementing team in Kingdom of Saudi Arabia was contacted to provide a solution for a cement job on the longest 9-5/8” casing run (+/- 15,000ft) in a challenging high-pressure gas field that was being developed

- The multi-stage cement operation required five downhole components to be launched during the job, including top and bottom first stage plugs, casing annulus packer freefall isolation cone, stage tool opening cone, stage tool opening cone and second stage displacement shut-off plug

- The customer wanted to improve operational efficiency by having all components pre-loaded in a controlled shop environment eliminating personnel exposure

Expro Excellence

- The modular body design of the 13-3/8” x 9-5/8” Gen-X Cement Head allowed for an industry first all five required plugs and cones to be pre-loaded in a controlled shop environment

- This resulted in significantly improved operational safety when benchmarked against a conventional plug container manifold that required personnel to make numerous trips into the red zone to manually function the valve and reload the plug container which consumes critical rig time and exposes personnel to potential hazards in the red zone

- Once casing was landed, well static time was decreased with Expro’s quick and easy tool rig-up that allowed for optimal time management and wellbore fluid conditioning

- The wireless components provide hands-free, automated operation of all equipment, allowing for remoteoperated launch of all plugs “onthe-fly”. Eliminating the need to stop pumping and reciprocating, reducing the likelihood of costly and hazardous remediation for fluid migration during primary cementing operations

- Unlike conventional plug launchers, Expro’s RPL allows for displacement fluids to be pumped with rig pumps via top drive, maximizing flow rates to achieve turbulent flow for cement placement improving

Value to Client

- All downhole components were preloaded which resulted in improved operational efficiency and reduced exposure to personnel in the red zone

- Wireless functionality further eliminated personnel exposure in the red zone including all high-risk man riding operations

- Integration into the top drive provided increased capability to manipulate the casing string (reciprocate or rotate) resulting in improved operational efficiency

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU