Case Study

Leading Tubular Running Services trusted for multiwell CCS campaign

Contact

In Brief

Expro's expert Tubular Running Services supports multiwell CCS campaign

Region

Customer Challenges

- Our customer was developing an onshore carbon dioxide (CO₂) sequestration site as part of a larger carbon capture and storage (CCS) project on the US Gulf Coast in Texas

- Long-term integrity is a top priority for carbon storage projects and wells need to be designed and constructed to last on geological time scales

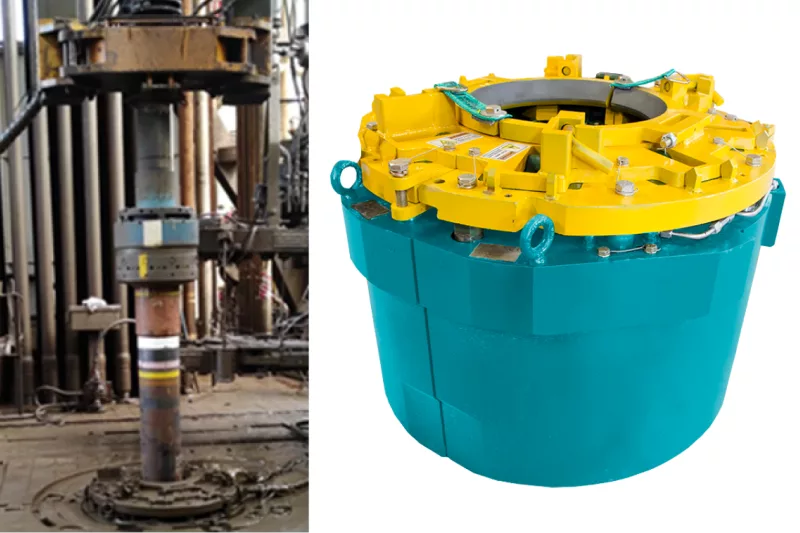

- To mitigate the potential for corrosion in the wells, our client used corrosion resistant alloy (CRA) tubulars for sections of the well exposed to CO₂

- Multiple CO₂ injection and monitoring wells were drilled to ensure optimal performance and a robust monitoring, measurements and verification (MMV) plan

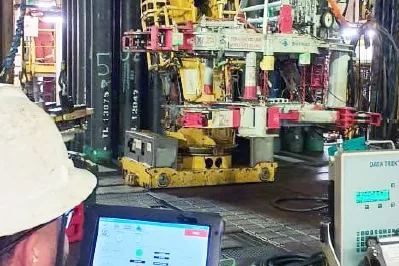

- Expro was chosen as the trusted partner for this high-profile project due to our longstanding relationship with our customer, our unique technologies to manage the handling and makeup of CRA tubulars and our expertise in running complex completion

Expro Excellence

- Expro ran 4-1/2”, 5-1/2”, 7” and 9-5/8” tubulars across 3 wells

- We used fine point dies to protect the outer chrome layer of the tubulars while making up connections. This limited penetration marks and eliminated iron transfer to the CRA tubulars, which could cause areas of weakness and lead to future integrity issues with the well

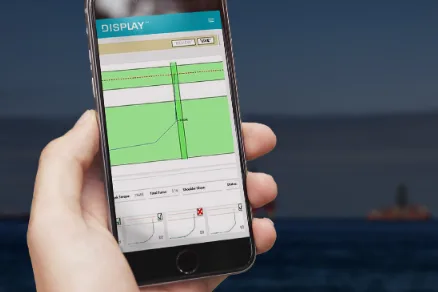

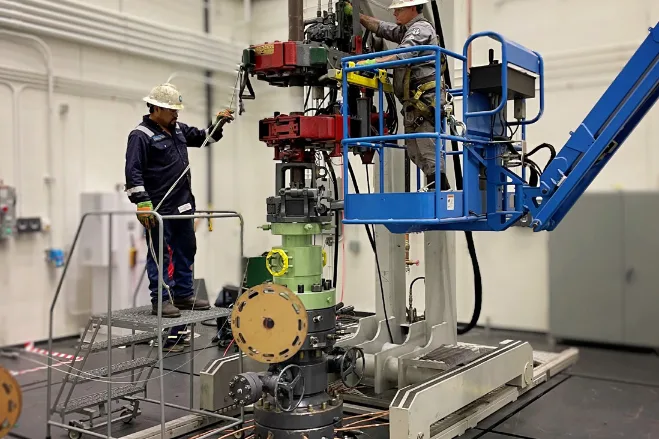

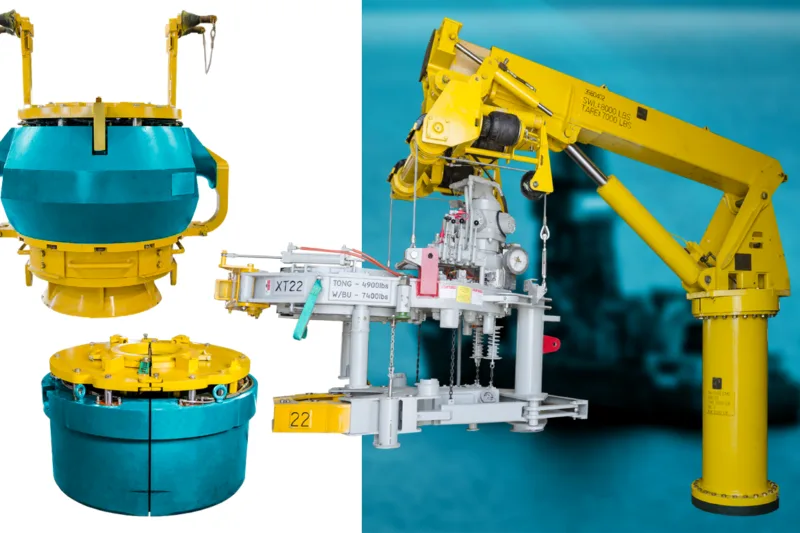

- Expro’s COBRA® Control Line Manipulator Arm was fitted with a bespoke roller to accommodate five separate control lines. This system was used to support and de-risk the manual clamping process whilst running completions with multiple fragile downhole monitoring systems

Value to Client

- Expro successful ran CRA tubulars and complex completions on three wells as part of the initial field development

- The COBRA® provided significant risk reduction by reducing the Red Zone risk exposure time of personnel on the rig floor associated with manually positioning permanent monitoring systems against the pipe

- Due to our wellsite performance and unique technology offerings, Expro has been requested to remobilize and continue running the tubulars for all future wells on this project

Contact

For further information, please contact ExproSES@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU