Case Study

iTONG™ impresses the deepwater market by reducing connection make-up times by 50%

Contact

In Brief

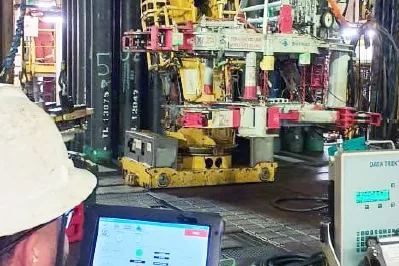

Expro successfully implemented advanced digital and remote technologies, notably the iTONG System, to enhance safety and efficiency by automating connection makeup and reducing personnel exposure in high-risk areas

Product Line

Customer Challenges

- A major operator in West Africa aimed to reduce Red Zone exposure and increase operational efficiency on their multi-well deepwater development campaign

- Recognizing Expro’s capabilities in this field, the operator supported Expro’s recommendations to deploy digital and automated technologies to help achieve their operational goals

Expro Excellence

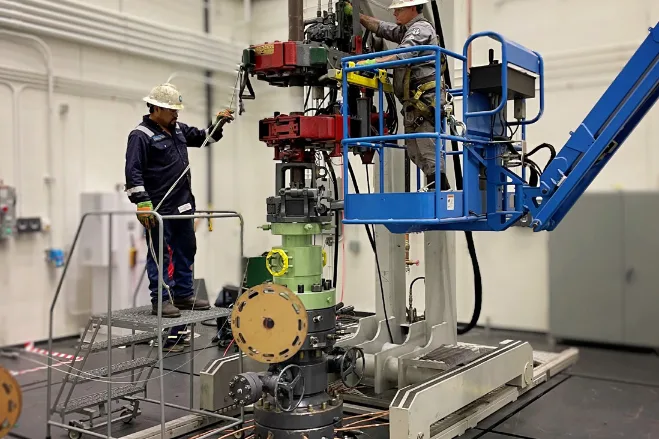

- Expro rose to the challenge and deployed a suite of digital, automated and remote-control equipment that delivered on the promise of risk reduction and improved efficiency

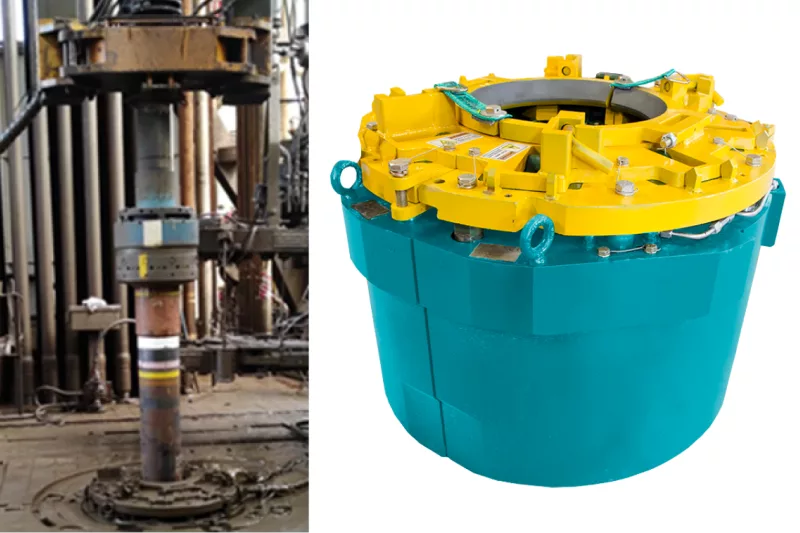

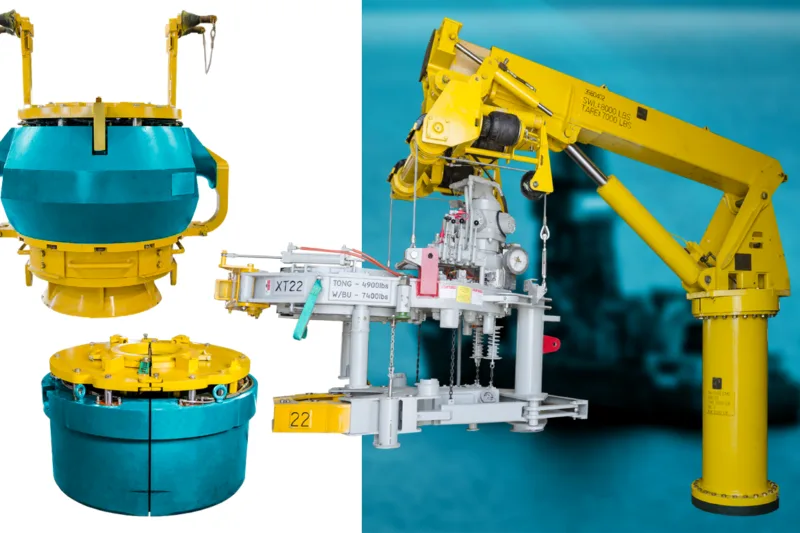

- Of most notable success was the introduction of iTONG™ - the industry’s most technologically advanced tubular make-up solution, enabling the operator to complete an entire connection makeup, including makeup validation, with the push of a single button

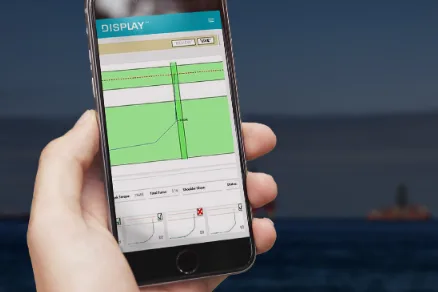

- iTONG™ markedly reduces operational risk by removing personnel from the Red Zone and assuring Connection Integrity using the AI-enabled iCAM™ - Connection Analyzed Make-Up System

Value to Client

- The deployment of iTONG™ reduced the client’s net well construction cost as a result of the improved efficiency

- By reducing connection make-up times by 50%, iTONG™ saved an estimated 10 hours of Rig Time per completion, equating to an estimated 15 hours of Rig Time savings per month

- The AI-enabled technology of iCAM™ is an integral part of the iTONG™ system, removing the human element of graph acceptance, and continuously monitoring and optimizing the operation of the Power Tong in real-time

- Following the success, the customer is exploring opportunities for additional iTONG™ deployments throughout their global well operations

- iTONG™ has set a new standard in efficiency, safety and wellbore integrity for future operations

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU