Case Study

SeaCure deliver optimized solution Africa - Cementing Tech

Contact

In Brief

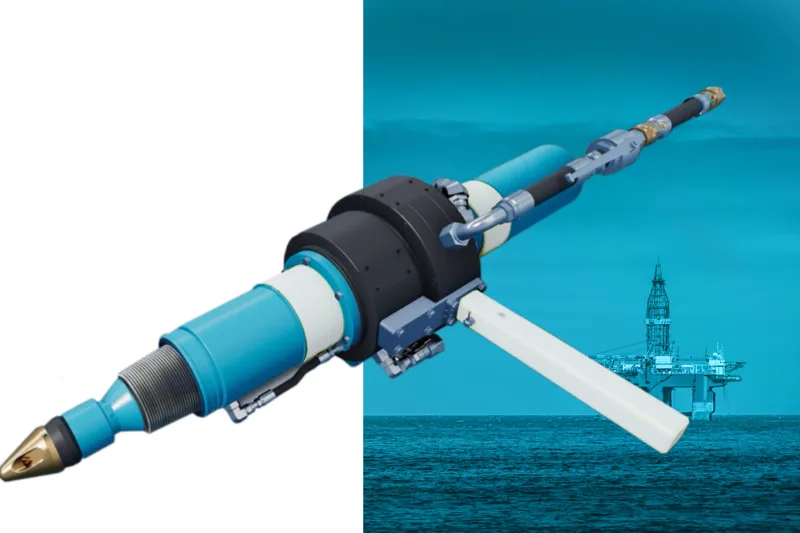

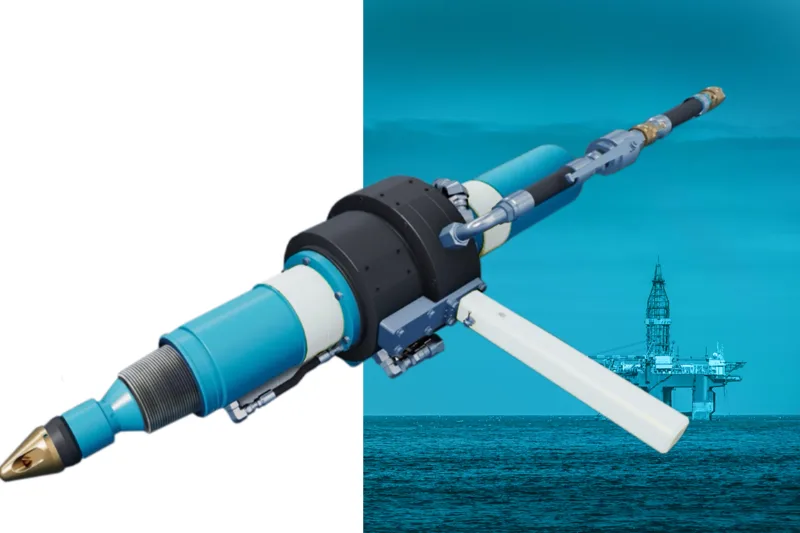

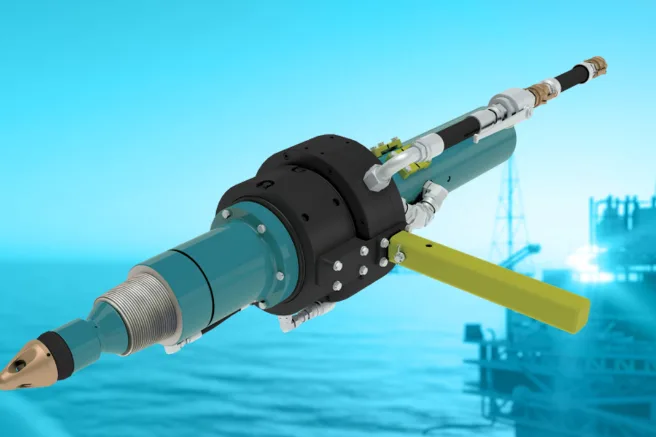

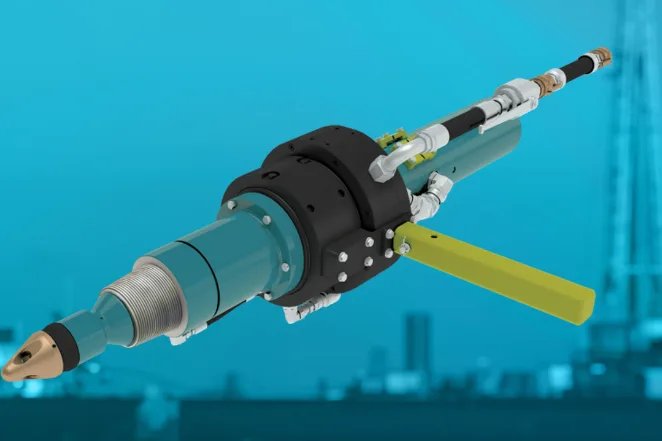

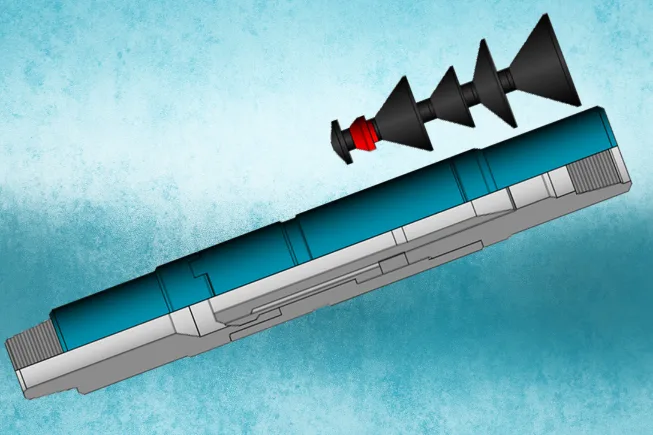

SeaCure®, QuikCure® and CoreCure® deliver optimized cementing solution offshore West Africa

Product Line

Customer Challenges

- Improve drill out of 20” shoetrack to mitigate risk of bit/BHA damage whilst also eliminating risk of CART seal leak and improving cement compressive strength development

Expro Excellence

- SeaCure® provides an optimized shoetrack solution whilst moving the primary seal for the cement job to the shoe plus QuikCure® to optimize the time for the tail slurry to reach 100psi compressive strength

Value to Client

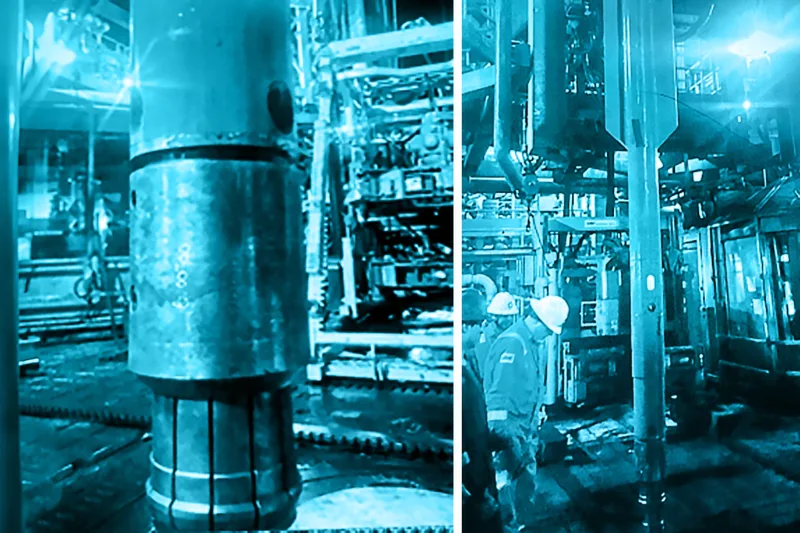

- Drilled out 20” shoe in 14 minutes with 17 ½” bit ensuring TD was reached in one run and mitigating risk of Bit/BHA damage, whilst also mitigating the risk of introducing swarf into the wellbore

- Improved early compressive strength development of primary cement job

- CoreCure® sample confirming hard, good quality cement at the shoe

- Risk of CART seal leak eliminated with the SeaCure® BHA latched into the shoe and the running tool ball valve left open throughout operations

- Successful 3,300 psi surface casing pressure test conducted

- Successful LOT achieved

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU