Case Study

VERSAFLO™ Switch delivers 6+ hours of savings

Contact

In Brief

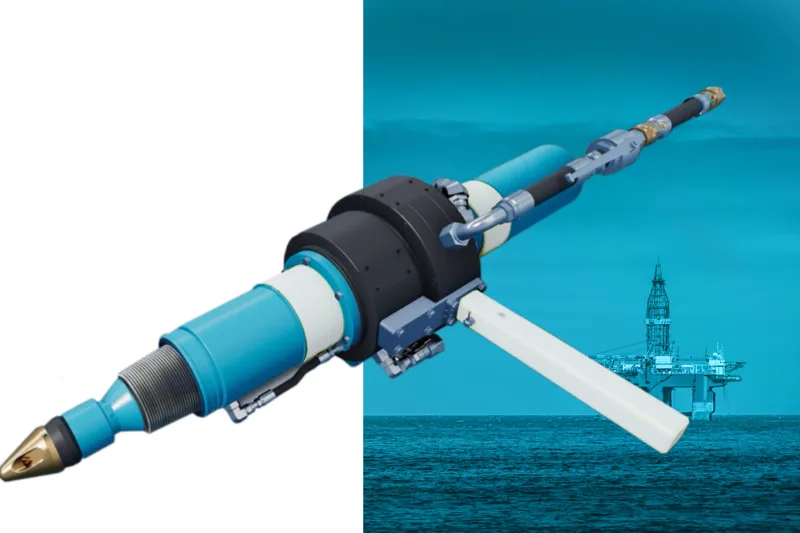

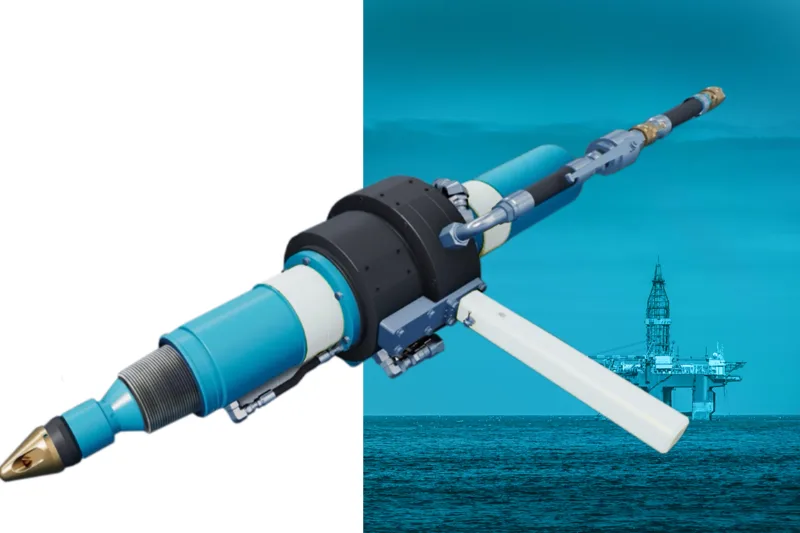

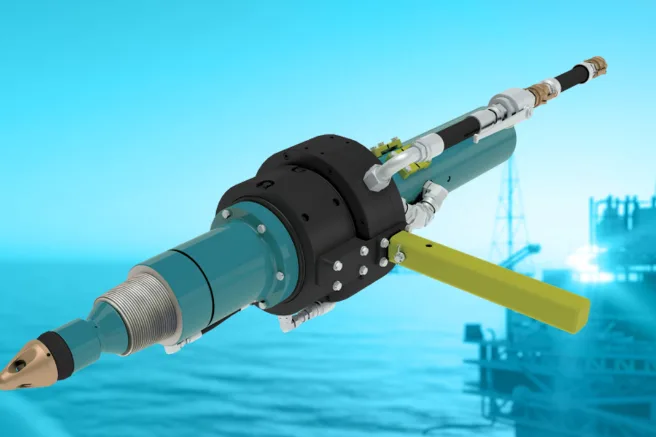

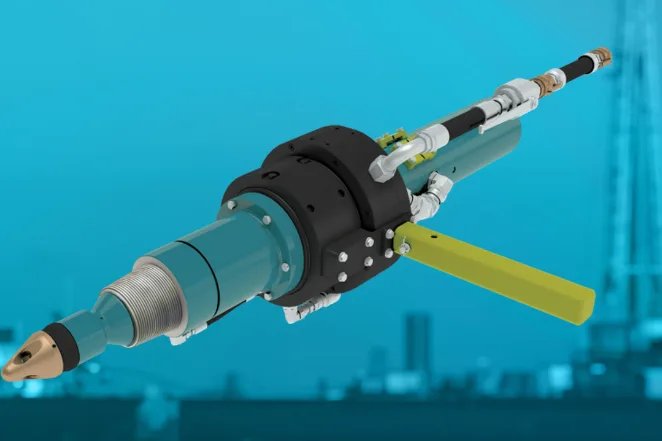

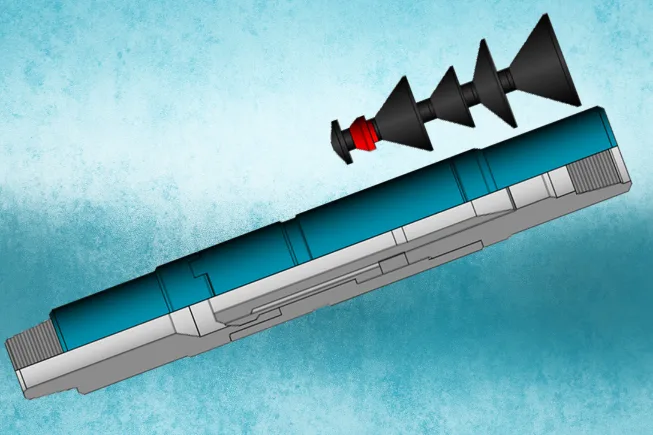

VERSAFLO™ Switch delivers 6+ hours of savings for deep water Mediterranean operator’s complex drilling and liner operations

Product Line

Customer Challenges

- A major IOC sought a solution to reduce time to trip out of hole with 12 1/4” drilling assembly as well as saving time to manage mud flow back while running 10” liner landing string in deep water drilling operations in the Mediterranean

Expro Excellence

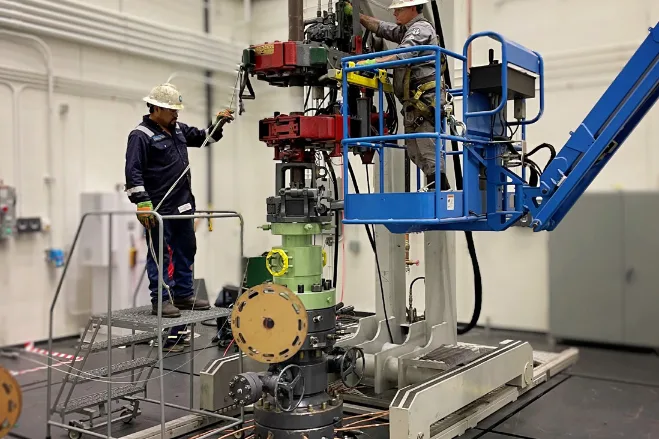

- Expro offered its VERSAFLO™ Switch patented flowback, fill-up and circulation tool that perfectly fits our client’s request to pump out of hole quickly and efficiently with the drill string on elevators, while circulating with the tool’s packer assembly. The VERSAFLO™ Switch was also proposed to run the landing string to take flowback without the need to mechanically connect the top drive to the drill string. Additional efficiencies can be seen by being able to install the VERSAFLO™ casing module and take flow back if required through the casing without the need to rig up separate tools for drill string and casing

Value to Client

- The drilling assembly was successfully circulated out of hole with the aid of the VERSAFLO™ Switch tool, saving our client a minimum of 50% of each connection times. Likewise, the 10” liner landing string was successfully run with VERSAFLO™ Switch to take mud flow back

- Cumulative rig-time saved is 6-7 hours equating to an estimated $240,000 USD of total rig-time costs

- The VERSAFLO™ Switch significantly reduced the amount of mud spilling on rig floor providing further fluids cost savings

- HSE exposure was improved by reducing personnel entry into the red-zone during operations; the VERSAFLO™ is operated from a wireless console inside the drill-shack

- Reduced wear and tear, improved life of consumable rig equipment (Saver sub and IBOP valve) saving additional costs and keeping personnel out of harm’s way

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU