Case Study

Shell – SeaCure & CoreCure 20” Surface Casing

Contact

In Brief

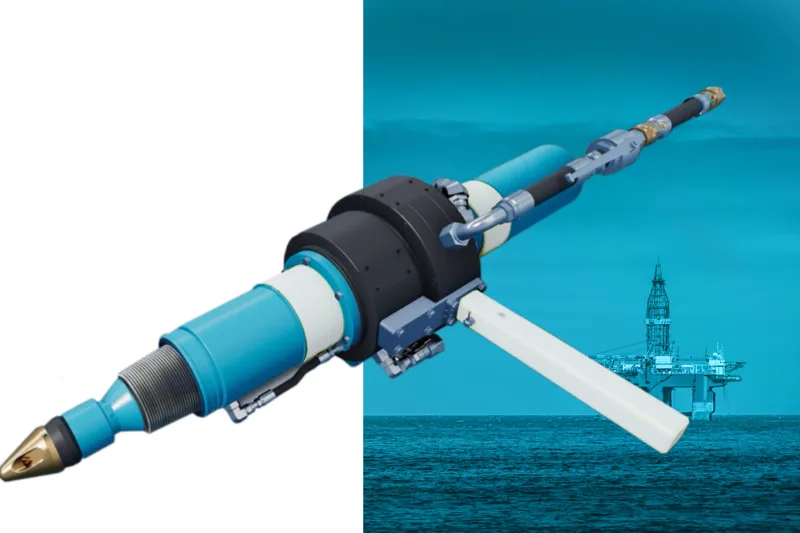

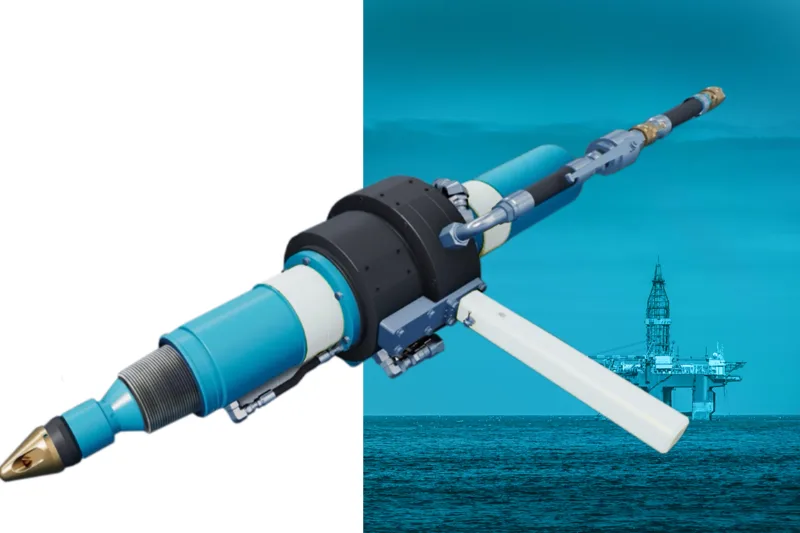

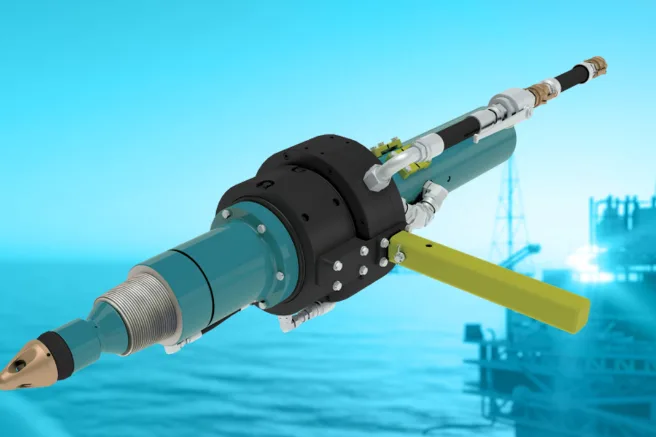

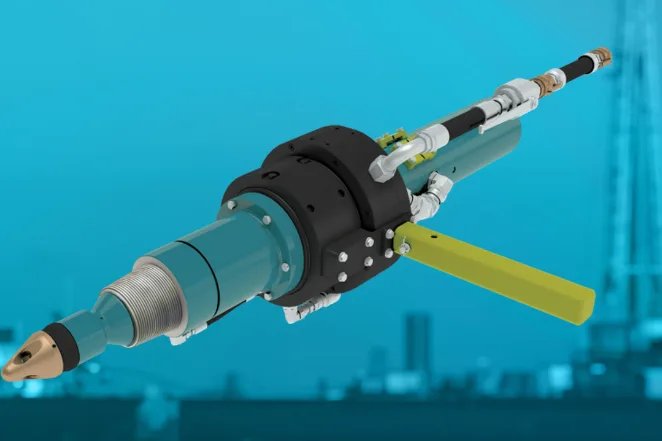

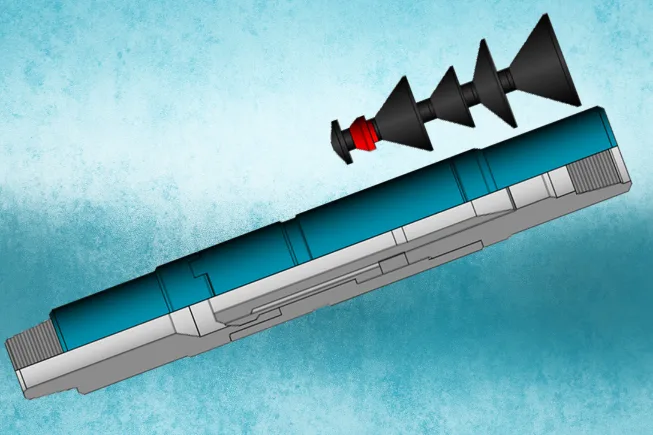

SeaCure® services significantly de-risks potential NPT event on 20” cement job

Product Line

Customer Challenges

Risks associated with mudline hanger suspension wash port pressure testing over cemented shoe track, and major risk exposure in float failure scenario for 20”

Expro Excellence

Expro’s SeaCure® offers open hole isolation throughout wash port manipulation and pressure testing over cemented shoetrack, and major risk exposure in float failure scenario for 20”

Value to Client

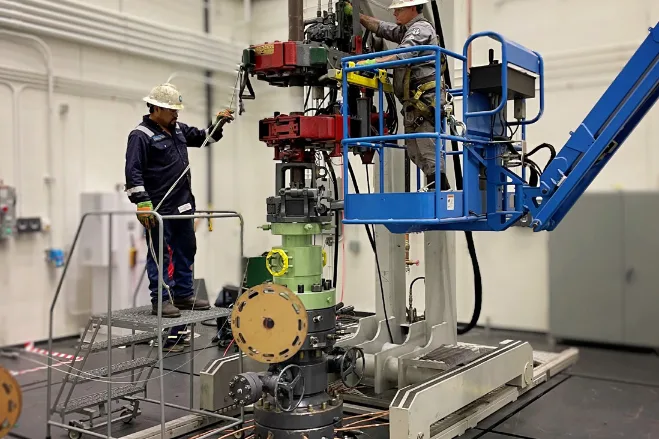

- Surface casing cement job executed with 1,662 bbls of 12.5ppg lead slurry and 222bbls of 16.0ppg tail slurry

- 30” x 20” annulus circulated clean with seawater post-cement job

- Open hole isolation with stabbed in SeaCure® throughout washport manipulation and pressure

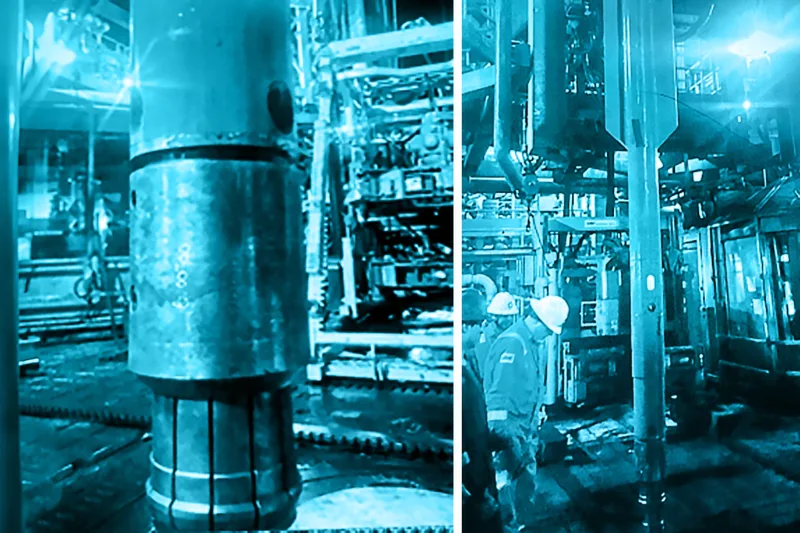

- CoreCure sample confirming hard, quality cement at shoe

- Drilled SeaCure® shoe out in ~60 minutes

- Zero NPT

- Pressure tested casing on green cement to 500 psi (34 bar) with inner string engaged, removing the risk of a wet shoe

- Achieved the required LOT at 20” shoe after the drill-out

Contact

For further information, please contact cementing@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU