Case Study

Ithaca Energy, North Sea – QuickCure, CoreCure & SeaCure

Contact

In Brief

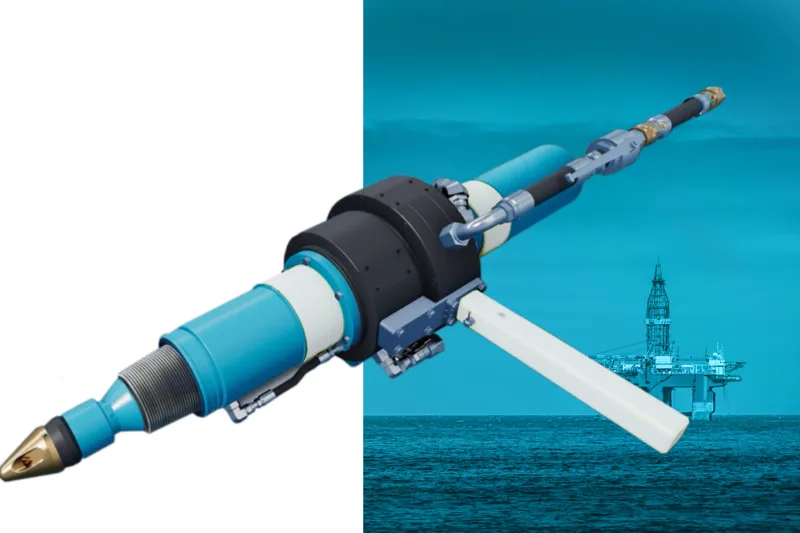

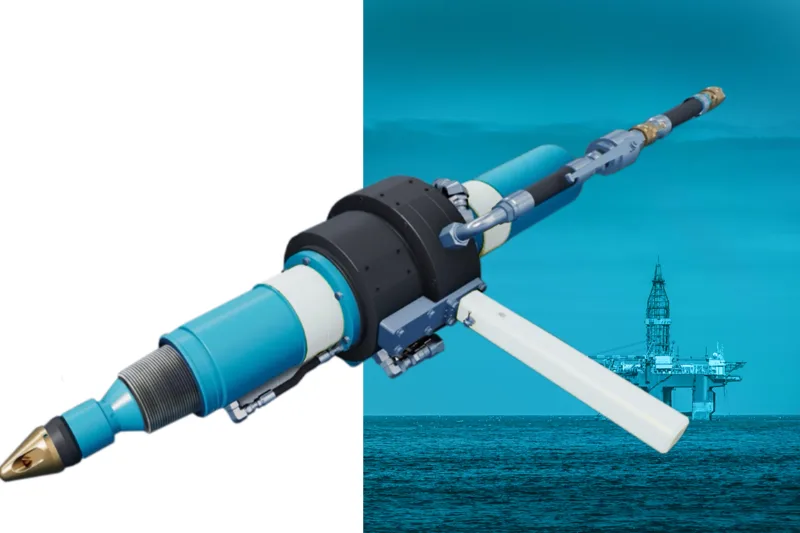

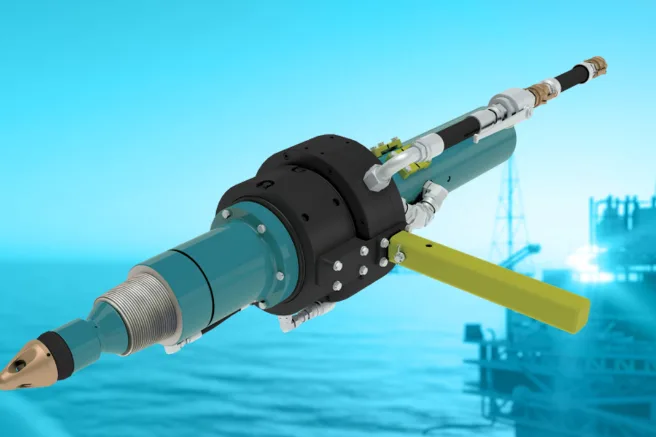

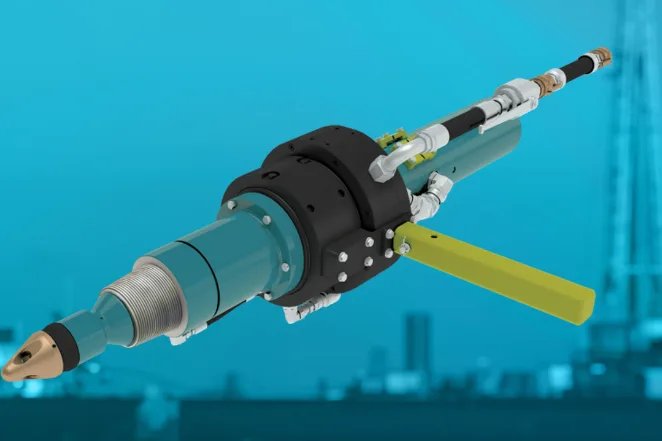

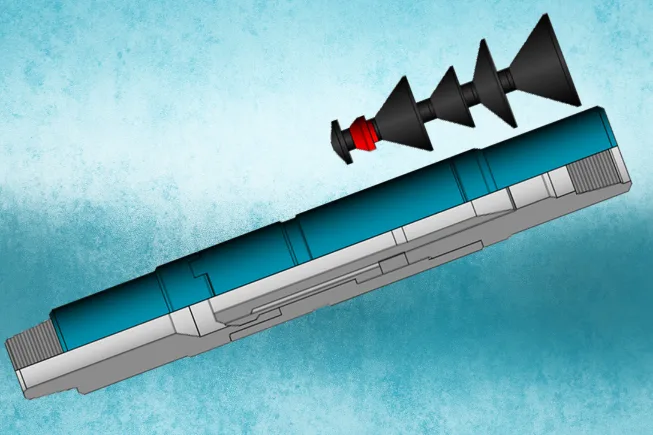

SeaCure®, QuikCure® & CoreCure® delivers full riserless cementing solution for North Sea operator

Product Line

Customer Challenges

- Long conductor wait on cement with G-neat slurry and the requirement for either a clean out trip to drill ahead with 8 1/2" pilot hole or major risk of stuck BHA without a clean out trip

Expro Excellence

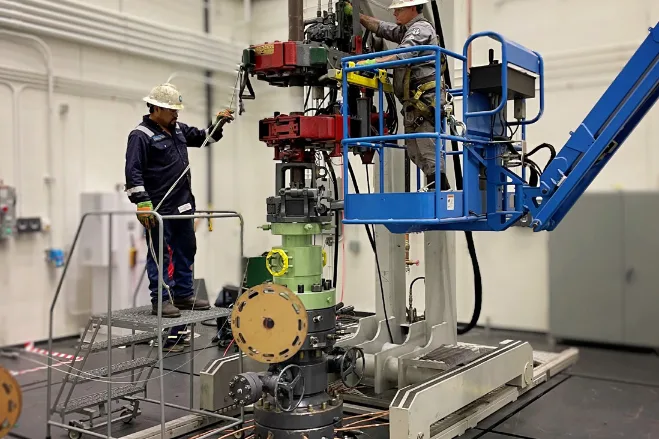

- QuikCure® reduced the conductor WOC and SeaCure® provided zero shoetrack solution for optimized drill out of 8 1⁄2”pilot hole BHA through 20” AND 13 3/8” shoetracks

Value to Client

- Reduced conductor WOC time by ~50% with data capture evidence to show cement hydration at just 3 hours after placement of QuikCure® heat sweep

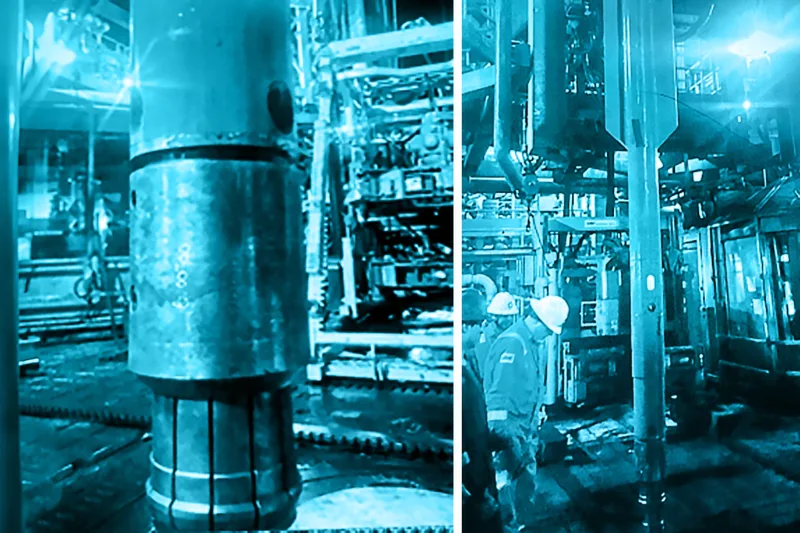

- Drilled out 20” shoe in 15 minutes with 8 1⁄2” pilot BHA – removing the requirement for dedicated clean out run / major risk

- Allowed 8 1⁄2” pilot hole drill ahead of 13 3/8” surface casing shoe with no BHA failure and bit drilled > 7,000 to section TD in one run, pulling 1-2 on dull grade

- Surface casing pressure test carried out on green cement with SeaCure® inner string to 2500psi prior to running BOP

- Saved rig time by utilizing the same simple cementing stand for conductor and surface casing cement jobs

Contact

For further information, please contact cementing@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU