Case Study

Custom solution sets record casing string run time

Contact

In Brief

Expro’s tailored solution, combined with operational planning and execution, led to a record setting casing run, with a total of 5 hours saved and zero rejected connections

Product Line

Region

Customer Challenges

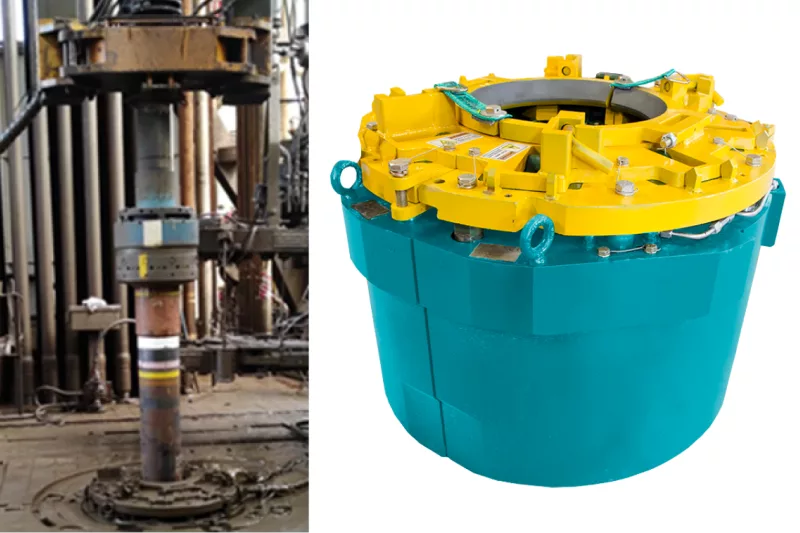

- A supermajor operator in Guyana sought to optimize running their 9 5/8 in. x 9 7/8 in. x 10 3/4 in. tie back string, including a section of 17Cr, while utilizing four different casing sizes to use up additional inventory. Part of the challenge with using multiple types of casing for one string include inherent inefficiencies with swapping tools during operations, which contribute to costly non-productive time (NPT). Along with the inefficiencies of swapping tool, the process will require personnel to enter the Red Zone introduce further hazards to the job

Expro Excellence

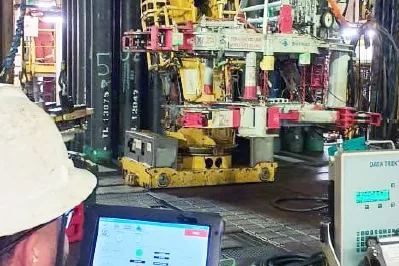

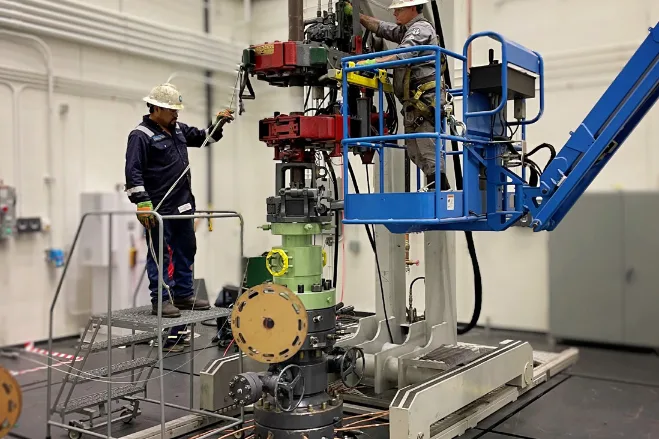

- Expro’s utilized multiple casing technologies that not only eliminated the need to swap tools to accommodate different casing types, but also allowed for faster run times and removed personnel from the Red Zone. Expro utilized the Mega Spider, EXTENDED RANGE™ Elevator, Tong Manipulation Arm (TMA), and VERSAFLO™ HD Tool, which are specifically designed to accommodate running multiple casing sizes with one set of equipment while reducing Red Zone entries

Value to Client

- Expro’s tailored solution, combined with operational planning and execution, led to a record setting casing run, with a total of 5 hours saved and zero rejected connections. Due to the size versatility of the Mega Spider and EXTENDED RANGE™ Elevator equipment package, the casing string was installed without requiring tools to be swapped as the OD of the casing changed and contributed to the time and direct cost savings. Additionally, the TMA system, which not only allows for the manipulation of Expro’s remote tong system, but also supports the full weight of the tong, contributed to the efficiency gains during the installation of the casing string, and reduced the need for personnel in the red zone

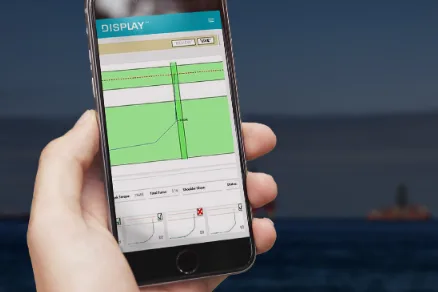

- Expro’s VERSAFLO™ HD Tool, a specialty fill-up and flowback tool that can be utilized on both casing and drill pipe, seamlessly reduced the time to crossover between the casing and landing strings during the operation, which greatly contributed to the overall efficiency gains during the operation

- Prevented NPT from tool swaps with versatile equipment package

- Remove personnel from the Red Zone with remote tong manipulation

- Zero rejected connections recorded

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU