Case Study

Creating savings through safe operations

Contact

In Brief

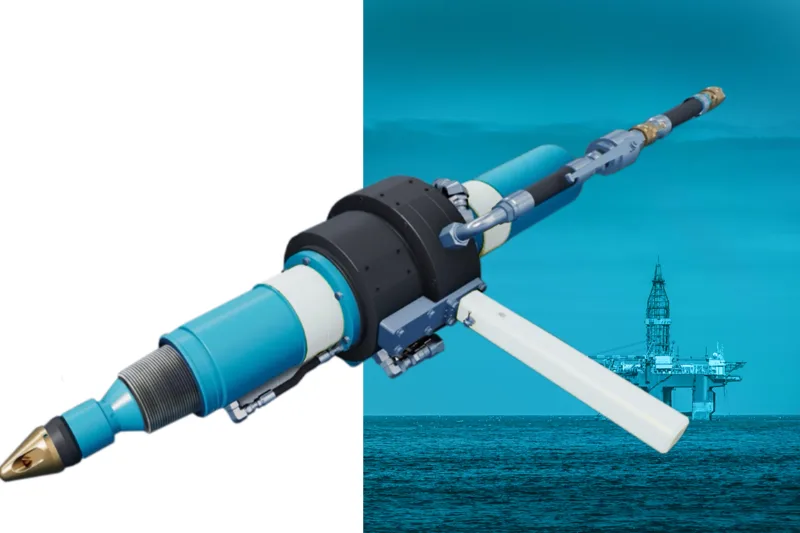

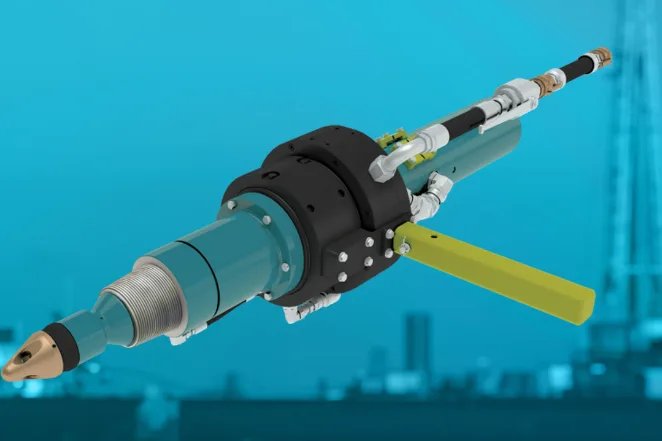

Expro was able to develop a safe running procedure with the use of the 750-Ton J-Slot Tool, to allow for the safe completion of this operation in Brazil

Product Line

Region

Customer Challenges

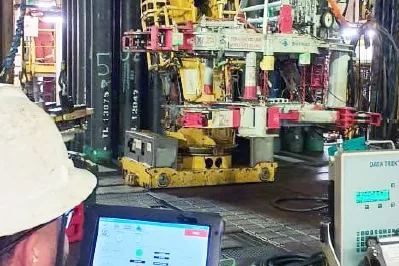

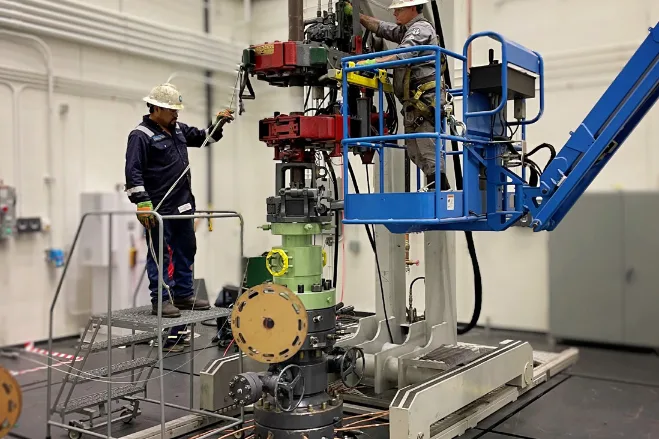

- An operator in Brazil approached Expro about running their 22” surface casing string offline

- In order to run this open water string offline, the rig would need to transfer the casing string from the auxiliary rotary to the main rotary upon completion of the drill ahead operation

- Expro recommended the 750-Ton J-Slot Tool to complete this operation due to the success within the Gulf of Mexico with similar operations

- Our experience in previously completed operations led us to make procedural adjustments to our equipment, accommodating differences in the rig set up. This enabled the equipment to be fit for purpose

Expro Excellence

- By working with the customer and rig personnel, Expro was able to develop a safe running procedure with the use of the 750-Ton J-Slot Tool, to allow for the safe completion of this operation in Brazil

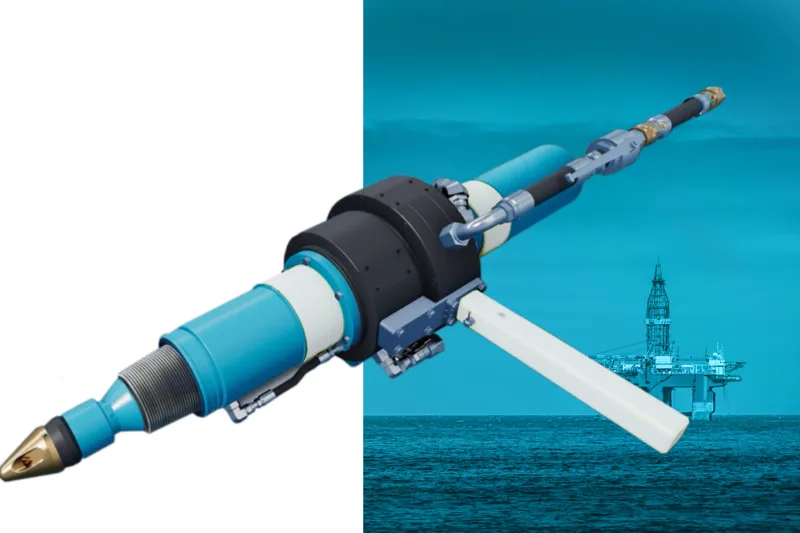

- With the ability to run the casing string offline, the customer was able to save over a day of rig time and successfully transfer the casing string after the

drill ahead operations - The use of the J-Slot tool allowed the rig to complete this operation without having to complete a dangerous “soft break” operation

- This same procedure can be used to complete hang off operations on other surface casing strings or for the movement of other mudline equipment

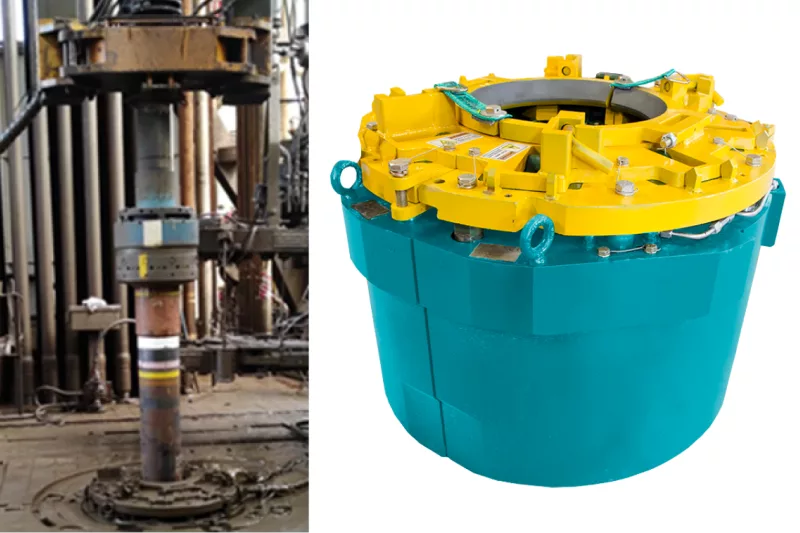

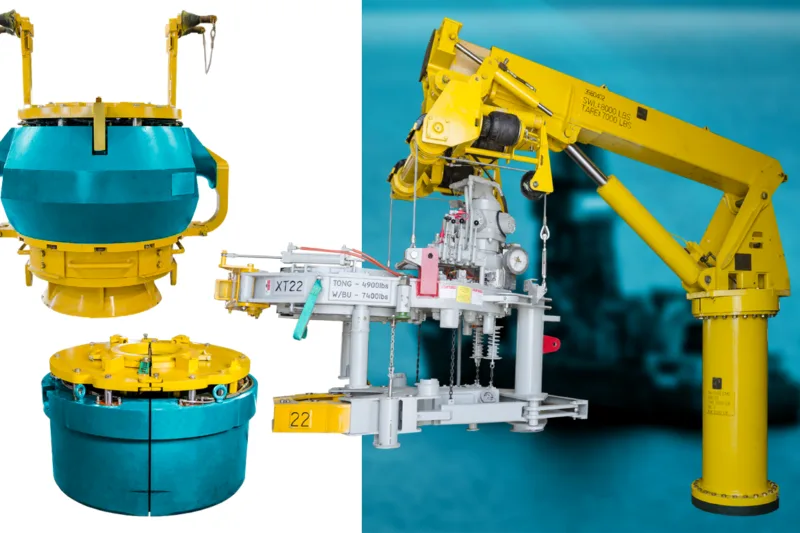

- Technologies used – Well Construction / Casing

- Main technology for handoff

- J-Slot Tool and supporting equipment

- Supporting technologies for casing running operations

- RTS-H XT22 Tong Cassette and Carriage

- 1250 Ton Slip-Type Extended Range™ Elevator and Spider

Value to Client

- The ability of the customer to run this casing string offline and simply transfer it to the main rotary after the completion of the drill ahead operations saved approximately 26 hours of rig time and over $542,000

- The use of this technology highlights Expro’s ability to save our customers time and money while not compromising the safety of onboard operations

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU