Case Study

CBI tool enhances hole cleaning and ECD management in North Sea

Contact

In Brief

A North Sea operator sought a solution to remove excessive accumulation of cuttings and manage equivalent circulation density (ECD) in a high angle 17½” section of a well where the formations are renowned to be unstable.

Product Line

Customer Challenges

- A North Sea operator sought a solution to remove excessive accumulation of cuttings and manage equivalent circulation density (ECD) in a high angle

171/2” section of a well where the formations are renowned to be unstable. The initial build up was to be performed in the 24” section in the Nordland Group where the angle was to be built up to over 35° and the 20” casing was to be set at 759m MD. Along the consecutive 17 1/2” section, the build up was to be continued to a sail angle of 67.8° over the Utsira and Skade Section TD was planned at 2050m MD in the undifferentiated Hordaland. Offset wells have posed serious problems with wellbore instability and consequential hole cleaning issues

Expro Excellence

- Based on the unstable formations in the area and high hole angle requirement of over 35°, Expro recommended to install the 5⅞” series CBI™ Cutting Bed Impellers in the 17½” section

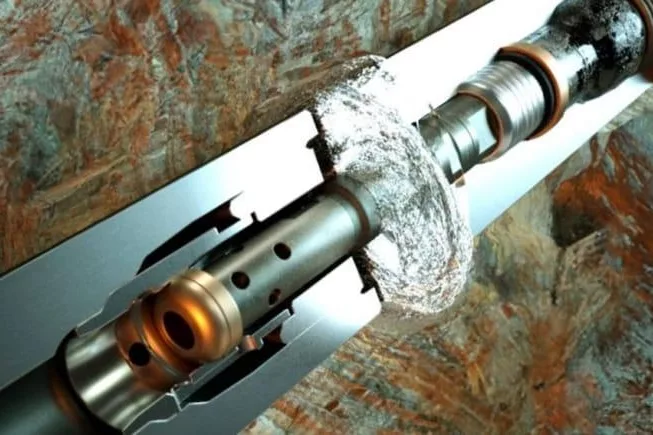

- The CBI™ tool is a downhole drill string tool used in deviated wells where excessive build-up of cuttings causes drilling issues, typically in hole angles greater than 30°

- The solution included spacing of one tool per two stands made up to the 5⅞” drill pipe, covering a total length of 1351 meters

Value to Client

- The hydraulic and mechanical dual acting mechanism in the CBI™ tool removed cutting beds efficiently inside the casing and in the open hole without distressing the unstable formation

- Its specialized design allows for easy removal of cuttings that tend to settle out of the mud in high-angle sections of the wellbore

- Drilling the 17½” section using Expro’s CBI™ tool showed a trend on both pick-up and slack-off weights, which followed a friction factor of 0.16—nearly matching the predicted factor of 0.15

- The application of the CBI™ tool in this case also improved ECD control and helped ease tripping and the subsequent 13⅜” casing run, resulting in reduced non-productive time (NPT)

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU