Case Study

HI TOOL® completes 8 1/2" section saving 45 drilling hours

Contact

In Brief

With the HI TOOL® at the top of the BHA we achieved extremely steady parameters (MSE) and completed the section with extremely good RoP

Product Line

Customer Challenges

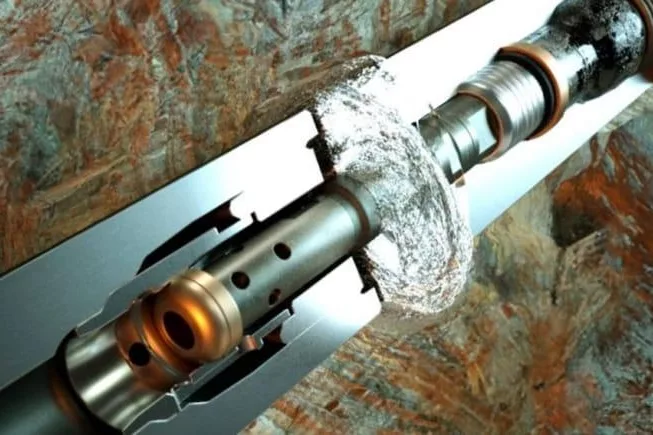

- The Expro HI TOOL® (Harmonic Isolation Tool) was deployed in a offshore development well in Gabon. The application while drilling the reservoir section holding verticality while maintaining constant parameters, and to minimize corrective actions by the BHA which would lead to smooth running of the 7” production tubing afterward

- The BHA was a rotary steerable (RSS) with the placement of the HI TOOL® at the top of the BHA in order to decouple the vibration from the string down into the M/ LWD preventing failure and thus additional NPT trips. Typically, this section is drilled with 1-2 BHA runs

Expro Excellence

Placement of the HI TOOL® at the top most point of the BHA (#12) replacing what is normally an integral blade stabilizer; typically, Expro’s aim to replace an already planned stabilizer thus no disruption to the directional capabilities of the BHA. The top position of the HI TOOL® was optimal as most of the damaging harmonics were string generated

Value to Client

- In this section, with the HI TOOL® at the top of the BHA we achieved extremely steady parameters (MSE) and completed the section with extremely good RoP. The bit came out in re runnable condition (1,2,WT,C,In,TD)

- Significant reduction in SS-vibe time

- Lateral vibes in green all the way (level 1-2)

- Improved RoP by 45% with constant parameters

- Improved MSE efficiency of the BHA

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU