Case Study

HI TOOL® Harmonic Isolation Tool optimizes drilling of lateral wells in Permian Basin

Contact

In Brief

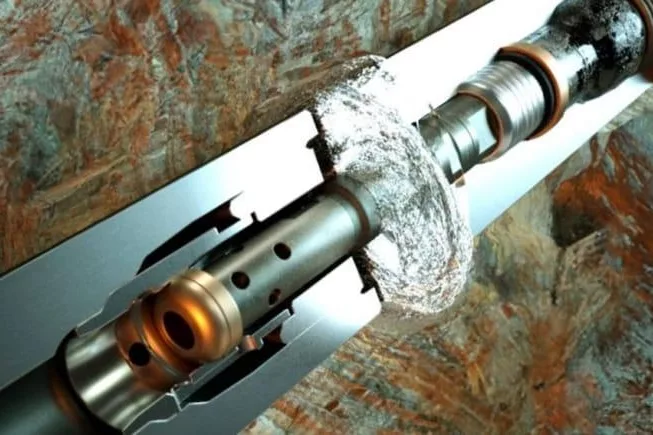

By reducing wear, the HI TOOL® extends the life of BHA components

Product Line

Region

Customer Challenges

- A West Texas operator sought a solution to optimize drilling capabilities

- For this application, two wells utilized Expro’s 800 series HI TOOL® Harmonic Isolation Tool. The tool was placed above the RSS and MWD LWD in order to protect these critical BHA components and support increased drilling parameters

Expro Excellence

By reducing wear, the HI TOOL® extends the life of BHA components. It also allows the entire face of the bit to stay more directly engaged with the rock which results in a higher ROP

Value to Client

- The two wells utilizing the HI TOOL® were compared to two offset wells without any vibration mitigation strategies, with all wells operating within similar parameters. The wells with the HI TOOL® benefitted in multiple ways, including increased ROP, increased section length, reduced of number of trips, and reduced time to complete the lateral sections

- Increased ROP by an average of 39%

- Increased section length by an average of 4200 ft.

- Reduced the average number of trips by 2.5

- Wells with the HI TOOL® completed the operation an average of 5 days sooner

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU