Case Study

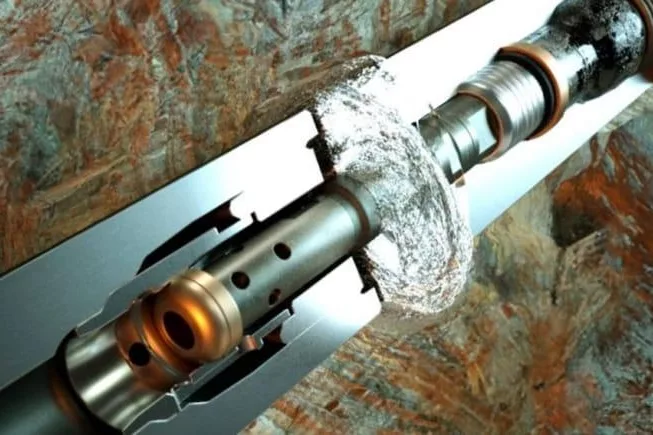

HI TOOL® Harmonic Isolation Tool reduces vibrations in challenging Papua New Guinea formation

Contact

In Brief

The 800 Series HI TOOL® successfully mitigated stick-slip and reduced lateral shocks in the 8 1/2” hole section, with lateral shocks being almost nonexistent on the RSS assemblies in the lower section

Product Line

Region

Customer Challenges

An operator in Papua New Guinea wanted to reduce vibrations in the challenging Darai Limestone Formation

An operator wanted a solution to reduce lateral and axial vibrations in the challenging Darai Limestone Formation found in the highlands of Papua New Guinea. The stratigraphy sequence in this area is unreliable with lithology sometimes repeating itself due to faulting and folding which can lead to losses and potential stuck pipe

Expro Excellence

repeating lithology in the Darai formation was determined, it was decided to start with a cost- effective rotary assembly. The HI TOOL® was used on all of the assemblies in the 8 1/2” hole, and the RSS was picked up later, once out of the Darai formation

Value to Client

- The 800 Series HI TOOL® successfully mitigated stick-slip and reduced lateral shocks in the 8 1/2” hole section, with lateral shocks being almost nonexistent on the RSS assemblies in the lower section

- The first 8 1/2” run on a rotary drop assembly (20° to 17° inclination) with the HI TOOL® was comparable to the last run in the 12 1/4” section on a rotary packed assembly (build to 20°). The green plot shows the lateral shock reduction from the HI TOOL® versus the 12 1/4” section in red

- Reduced lateral shocks from 3Gs at the base of the 12 1/4” hole to 0.75G for the upper section of the 8 1/2” hole in the limestone

- Reduced stick-slip in the 8 1/2” hole section

- Lateral shocks in the lower 8 1/2” hole almost nonexistent on the RSS assemblies

- Lower section with almost zero shocks on RSS over a continued build to 45°

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU