Case Study

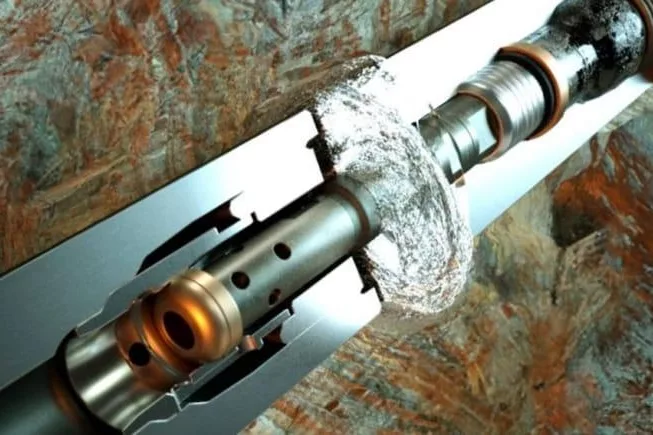

HI TOOL® Harmonic Isolation Tool results in successful coring run in West Texas

Contact

In Brief

The HI TOOL® was positioned above the core barrels in the bottom hole assembly (BHA) to reduce non-productive time (NPT), increase efficiency by minimizing vibrations and improving core quality, and eliminate unnecessary trips due to partially filled core barrels

Product Line

Customer Challenges

- A major operator sought a solution to retrieve quality core samples

- An operator requested the 800 series HI TOOL® Harmonic Isolation Tool to mitigate the harmful vibration harmonics observed when drilling a lateral 8 1/2’’ section. The goal was to protect the MWD tool while also increasing the overall efficiency of the drilling operation

Expro Excellence

- The HI TOOL® was positioned above the core barrels in the bottom hole assembly (BHA) to reduce non-productive time (NPT), increase efficiency by minimizing vibrations and improving core quality, and eliminate unnecessary trips due to partially filled core barrels

Value to Client

- The use of the HI TOOL® in the 8 1/2’’ section successfully retrieved quality core samples. The customer ran the HI TOOL® on four of the five planned coring runs with a starting coring depth of 9,225 ft. The run without the HI TOOL® was used as a data point to compare runs and showed a less steady rate of (ROP) compared to runs with the HI TOOL®

- Average ROP of 20.5 ft/h

- Successfully retrieved quality core samples

- Trial resulted in future runs with the customer

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU