Case Study

HI TOOL® improves drilling performance, sets field record ROP in a vertical well

Contact

In Brief

A Middle East operator sought a solution to reduce vibrations, improve performance and bit life.

Product Line

Region

Customer Challenges

- A Middle East operator sought a solution to reduce vibrations, improve performance and bit life

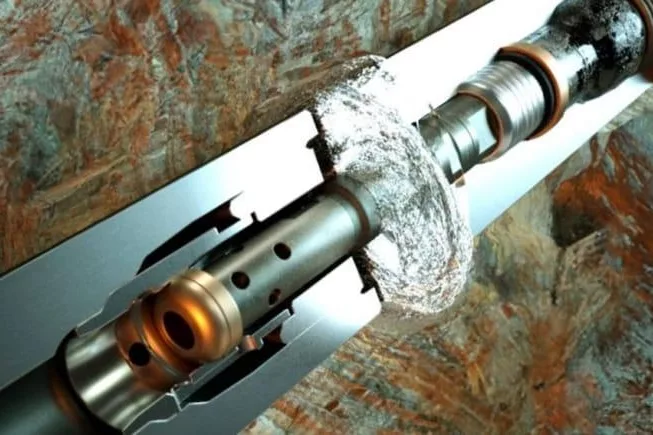

- The Expro HI TOOL® (Harmonic Isolation Tool) was deployed in drilling a 16” vertical section with a mud motor through the top interbedded formations. Its role was to protect the bit from the severe axial and lateral vibrations experienced on the previous assembly. The goal was to drill the 16” section shoe-to-shoe in one run, improve rate of penetration (ROP) and protect bit and bottom hole assembly (BHA)

Expro Excellence

The HI TOOL® was placed above the motor isolating the lower BHA, including a PDC bit, from upper string vibrations while maintaining verticality. The HI TOOL® was run as a second stabilization point above the motor to allow the PDC bit to sit evenly on the formation face, undisturbed by the string harmonics

Value to Client

- The HI TOOL® delivered on its objective, with significant improvements of axial and lateral shocks with lower orders of stick-slip. The performance of the HI TOOL® allowed the operator to apply higher weight on bit and achieve a constant rate of penetration, which resulted in a record for the field with 40% improvement in ROP. The 4,718-foot section was drilled in a smooth manner with the bit graded 1-1 WT in re-runnable condition

- Reduction of lateral and axial vibrations

- Smoother drilling throughout section

- Improved bit life and condition reflected by even wear

- 40% improvement in ROP

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU