Case Study

HI TOOL® prolongs BHA life to achieve first shoe to shoe 12 ¼” section in Sicily

Contact

In Brief

The HI TOOL® helped provide an effective method of control shock and vibration during the drilling of interbedded formations which are typically prone to major vibration issues

Product Line

Customer Challenges

- Our customer required a solution to reduce vibrations during drilling in order to minimize down hole tool (DHT) failure and the resulting need to execute multiple runs to drill a 12 ¼” section

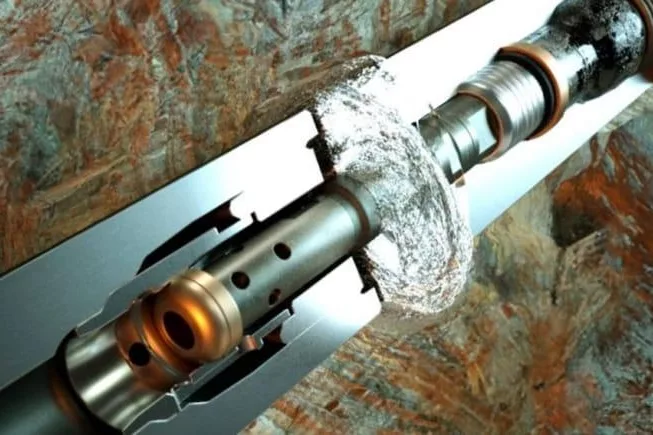

- Expro’s HI TOOL (Harmonic Isolation Tool) was run above the measuring/logging while drilling (M/ LWD) suite of tools

- The main goal was to prevent vibrations from travelling from the string down into the lower part of the bottom hole assembly (BHA); the HI TOOL® actively decoupled string harmonics through its flexible geared connection and mitigated lateral and axial vibration generated by the drillstring from the lower assembly where the M/LWD and RSS package was located

- The RSS and bit were therefore allowed to dynamically self-centre and drive the hybrid drill bit efficiently, while protecting valuable downhole equipment from premature failure

Expro Excellence

- Our HI TOOL® delivered its objective by protecting the MWD/LWD/DD tools from shocks and vibration, including stick slip, as seen from the log. This in turn led to minimized bit-whirl and supported prolonged bit life

- The logs show that only minimal shock levels were reported during the entire 12 ¼” section, consisting of clay, sandstone, shale, limestone and chert

- The HI TOOL® helped provide an effective method of control shock and vibration during the drilling of interbedded formations which are typically prone to major vibration issues, while achieving an unprecedented shoe-shoe run at a high rate of penetration

Value to Client

- Improved wellbore quality due to greatly reduced vibration energy impacting on the wellbore

- Significant improvement in ROP from the best offset in the field. This is first time the section was drilled shoe-to-shoe; significant reduction in section completion time

- Reduction of shock and vibration – we were able to make significant improvements compared to offsets of axial and lateral shocks with very low orders of stick-slip, resulting in prolonged life span of the bits’ cutting structure

- Expro’s HI TOOL® placed above the M/LWD suite isolated the lower BHA allowing for smooth running, which aided in maintaining wellbore verticality

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU